All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

- 10 Portable Standing Seam Roofing Machine

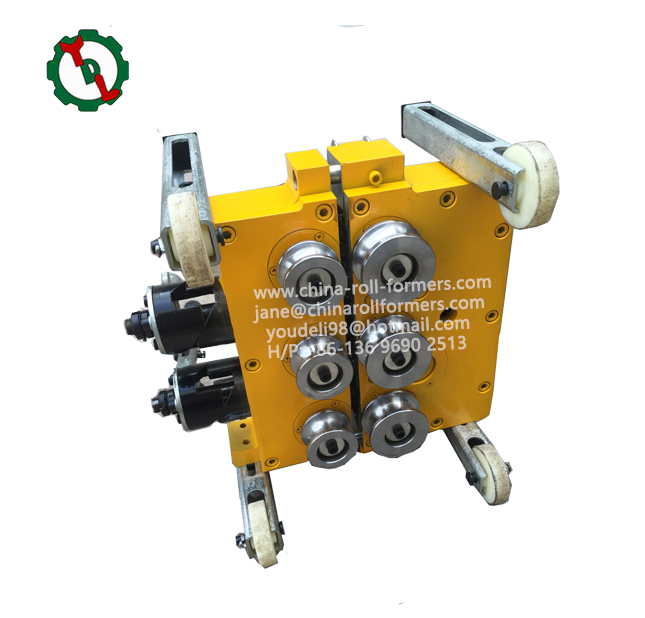

Introducing the Portable Adjustable Standing Seam Roofing Machine! This cutting-edge roofing machine is perfect for any job site, large or small. Its lightweight and portable design makes it easy to transport and set up in no time.

Equipped with an adjustable width stand, this machine can be used on any standing seam types. It is ideal for creating the perfect standing seam panels with precision, accuracy, and efficiency. Its high-quality construction and materials guarantee durability, longevity, and minimal maintenance.

The machine is designed with safety in mind, featuring protective covers and easy-to-access emergency stops. This ensures that operators can work safely and comfortably without any risk of harm. The machine's controls are easy to operate, and its adjustable settings allow for customized use based on specific roofing projects.

Not only is the Portable Adjustable Standing Seam Roofing Machine user-friendly, but it also provides outstanding results. Its seamless operation delivers a perfectly formed standing seam panel every time, with clean and precise lines that create a professional look that customers will love.

- 10 65MM Standing Seam Roofing Machine

The standing seam roofing roll forming machine is equipped with a series of rollers, which shape the metal sheets into standing seam profiles. The machine also comes with a cutting system, which ensures precise cutting of the panels to the desired length.

To ensure that the panels produced by this machine are of the highest quality, it is equipped with a high-precision control system. The control system monitors the entire production process and makes necessary adjustments to ensure that the panels meet the required standards.

The machine is made of high-quality materials that are resistant to wear and tear, ensuring its durability and long service life. It is also designed to be easy to operate and maintain, making it perfect for both small and large-scale roofing projects.

- 10 High Speed Hat Profile Machine

The Hat Profile/Omega Shape Purlin Roll Forming Machine is a specialized equipment used for manufacturing hat-shaped or omega-shaped steel purlins. Purlins are horizontal structural members used in roof framing to support the roof decking. They are commonly made of steel and are cold-formed by roll forming machines.

- 10 PU Sandwich Panel Machine

Functionality: The machine is designed to automatically produce PU sandwich panels of varying sizes, thicknesses, and densities. It typically includes a polyurethane foam mixer, a pouring system, a panel forming station, and a panel cutting device.

Process: The machine mixes the polyurethane components (isocyanate and polyol) in a controlled manner and then pours the foam between the metal sheets. The foam expands and cures, bonding to the metal sheets to form a sandwich panel.

Automation: Modern PU sandwich panel machines are highly automated, reducing the need for manual labor and improving production efficiency. The machine can automatically adjust the foam mixture ratio, panel size, and other parameters.

Quality Control: The machine typically includes systems for monitoring and controlling the quality of the foam and the sandwich panels. This helps ensure consistent and reliable product quality.

Applications: PU sandwich panels produced by these machines are used in a wide range of applications, including cold storage facilities, warehouses, industrial buildings, and even some types of residential construction.

Customization: Manufacturers often offer customized solutions to meet specific production needs, such as different panel sizes, thicknesses, or material requirements.

- 10 Floor Decking Roll Forming Machine

Web Floor Decking Roll Forming Machine: A Must-Have for Building Construction

In the field of building construction, the use of roll forming technology has become a popular practice due to its ability to produce high-quality and efficient metal sheets. One particular type of roll forming machine that has been widely used in this industry is the Web Floor Decking Roll Forming Machine.

The Web Floor Decking Roll Forming Machine is a specialized equipment that creates metal sheets, used as reinforced concrete flooring, called web floor decking. The machine operates by passing metal strips through a series of rollers, which bend and shape the metal strips to form a patterned web-like profile. This profile provides structural strength and support to the floor slab while the reinforced concrete is poured over it.

One of the primary advantages of the Web Floor Decking Roll Forming Machine is its ability to produce a large volume of web floor decking profiles quickly and economically. With the use of high-precision rollers, the machine can produce consistent and accurate profiles that meet specific design requirements. Furthermore, the machine's automatic control system ensures that the production process is efficient and seamless.

The Web Floor Decking Roll Forming Machine also offers versatility in terms of the type of materials it can work with. It can process a wide range of steel materials such as stainless, galvanized, and color-coated steel. This flexibility allows contractors to choose the most suitable material depending on their specific construction requirements.

Aside from its production and material flexibility, the Web Floor Decking Roll Forming Machine also offers safety benefits. Since the machine operates automatically, there is minimal manual intervention, which reduces the risk of worker injuries. Furthermore, the machine's roller design prevents the material from slipping or jamming during the production process, reducing the risk of material damage.

In conclusion, the use of the Web Floor Decking Roll Forming Machine is an essential component in building construction, particularly in reinforced concrete flooring. Its ability to produce a large volume of accurate and consistent web floor decking profiles quickly and economically, along with its material flexibility and safety features, make it a must-have equipment for any contractor. By incorporating this technology into their building processes, contractors can ensure a higher level of efficiency, safety, and quality in their construction projects.

- 10 Automatic Stacker

Color Steel Automatic Stacker for Double Furring Machine: A One-Stop Solution for Production Efficiency

Manufacturing color steel products for wall and roof cladding is a complicated process with a range of steps and machines. One of the essential machines in the production line is the double furring machine which shapes the color steel into the required profile. However, the machine can only produce the required design and size of the product. After that, the products need to be stacked, packed, and transported to the next stage of the production line, which is a tedious process if done manually.

This is where the color steel automatic stacker for double furring machine comes in. The automatic stacker is designed to automate the process of stacking the final products from the double furring machine. The machine is designed to work seamlessly with the double furring machine, taking the finished products and stacking them in the required size and shape, ready for the next stage of the production line.

Product Categories

Hot Articles

- October 1, 2024

In this article, we will explore the critical aspects of maintaining an electric seaming machine, covering everything from routine inspections to advanced troubleshooting, lubrication, and parts replacement.