In the domain of metal fabrication, the importance of selecting the appropriate machinery cannot be emphasized enough. The world of C channel roll forming, a pivotal technology in structural steel production, necessitates a profound understanding of the key features and specifications associated with the roll forming machine. In this extended exploration, I will delve into the indispensable aspects that demand careful consideration when opting for a C channel roll forming machine.

Introduction to C Channel Roll Forming Machines

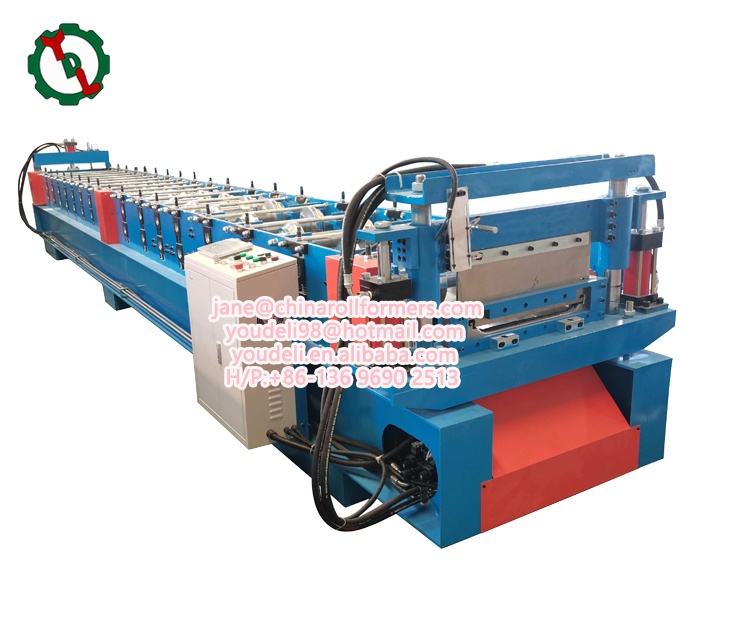

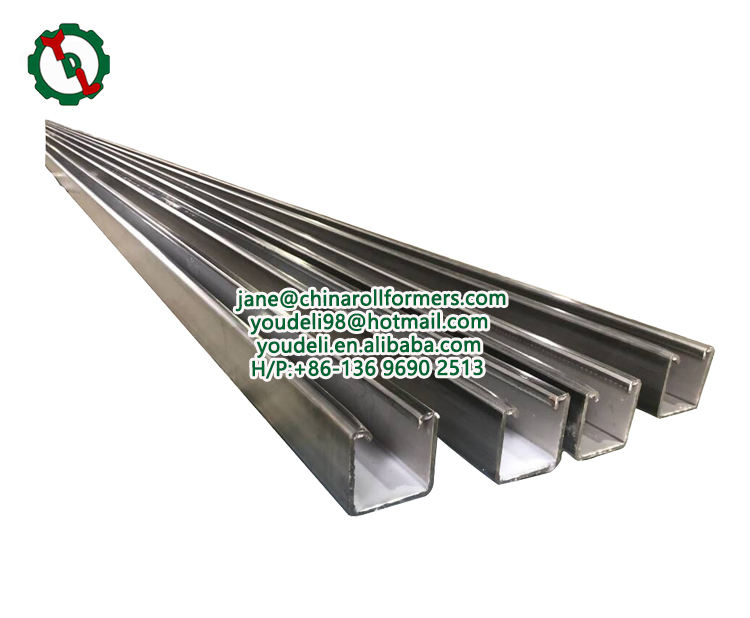

C channel roll forming machines play a crucial role in the production of a diverse array of structural elements, with C-shaped steel profiles standing out as prime examples. These profiles boast excellent tensile strength, bending resistance, and compression performance. The roll forming process ensures precision in dimensions, automated length cutting, and a high degree of automation. The resulting C-shaped steel finds applications in a myriad of industrial and civil engineering structures, ranging from main factories, warehouses, and aircraft hangars to exhibition halls, theaters, sports stadiums, and market roofing and wall support.

Key Features Revisited:

- Material Compatibility:

The foremost consideration in selecting a C channel roll forming machine is its compatibility with various materials. Superior machines should proficiently handle a spectrum of materials, including different grades of steel, ensuring versatility in production for a wide array of applications.

- Forming Speed and Production Capacity:

Beyond basic considerations, the forming speed and production capacity of the roll forming machine are critical factors influencing overall efficiency. A comprehensive evaluation involves an in-depth examination of the machine’s speed capabilities and production output to ensure alignment with specific project requirements.

- Customization Options:

A reliable C channel roll forming machine distinguishes itself by offering extensive customization options. This involves the flexibility to adjust dimensions, thickness, and other parameters according to the unique specifications of the desired C channel profiles. The ability to customize ensures adaptability to diverse project requirements and industry standards.

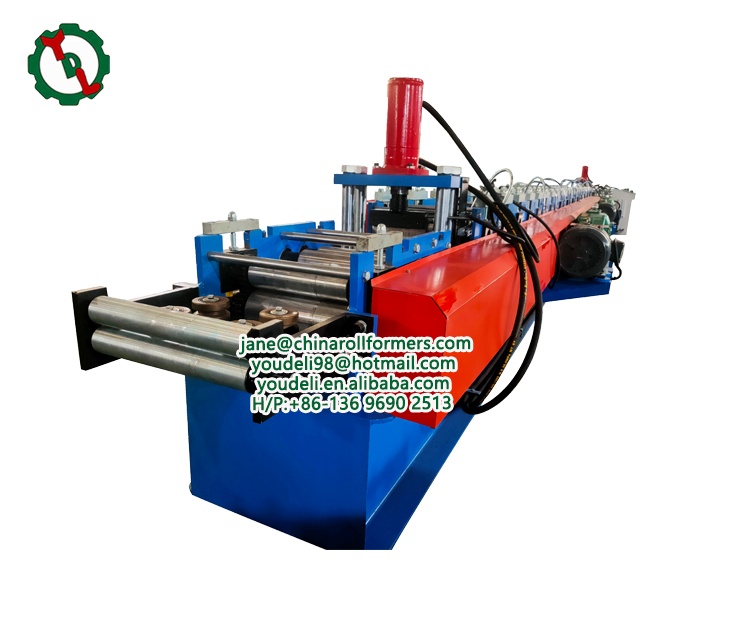

- Automation Level:

Automation remains a pivotal feature that sets advanced roll forming machines apart. A high level of automation not only enhances production efficiency but also significantly reduces dependency on manual labor. Look for features such as automatic length cutting, hole punching, and other automated processes to streamline operations.

- Tooling Design:

The design and quality of the tooling have a profound impact on the precision and consistency of the formed C channels. Optimal tooling design ensures the smooth and accurate shaping of profiles, contributing to the overall quality of the final product. Consider machines with innovative tooling solutions for enhanced performance.

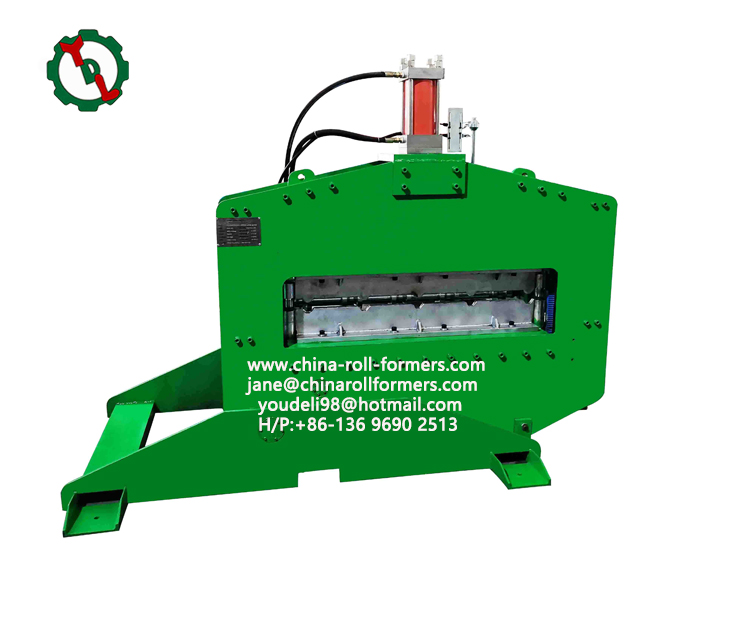

- Ease of Installation and Maintenance:

A user-friendly C channel roll forming machine not only simplifies installation but also ensures ease of maintenance. Machines with intuitive controls, comprehensive documentation, and readily available support contribute to minimized downtime and continuous production.

Technical Specifications Unveiled:

- Roll Forming Stations:

The number of roll forming stations in a machine is a critical determinant of its forming capabilities. Machines with a higher number of stations can produce complex profiles with higher precision. A thorough evaluation of the specific requirements of C channel profiles aids in determining the optimal number of roll forming stations for your application.

- Power Requirements:

A comprehensive understanding of the power requirements of the roll forming machine is essential for seamless integration into your facility. Factors such as electrical specifications and power consumption should be carefully considered to ensure compatibility with your existing infrastructure and energy constraints.

- Dimensions and Weight:

Practical considerations such as the physical dimensions and weight of the machine play a vital role in both installation and transportation. Ensure that the machine aligns with the available space in your facility and can be transported if necessary. Consider machines with a robust yet compact design for efficient space utilization.

- Material Thickness Range:

Different projects may necessitate C channels of varying thicknesses. Verify that the roll forming machine can accommodate the full range of material thicknesses you anticipate working with. A versatile machine capable of handling diverse material thicknesses ensures flexibility in catering to varied project requirements.

- Control System:

The control system serves as the brain of the roll forming machine. Opt for machines equipped with advanced control systems, such as programmable logic controllers (PLCs), for precise and efficient operation. A user-friendly interface contributes to the ease of operation, reducing the learning curve for machine operators.

Advanced Features for Unparalleled Precision:

In the realm of C channel roll forming machines, the pursuit of excellence extends beyond the basics. Delving into advanced features, consider machines equipped with innovative tooling systems that not only ensure precision but also facilitate swift adjustments for diverse profiles. Optimal tooling design is the linchpin, contributing to the seamless transformation of raw materials into precise C-shaped steel profiles.

Additionally, explore the intricacies of the control system. A cutting-edge control setup, featuring programmable logic controllers (PLCs) and intuitive interfaces, enhances operational efficiency. This advanced technology empowers operators to navigate complexities with ease, ensuring a seamless production process.

Material compatibility takes center stage, emphasizing the machine’s ability to handle an extensive range of materials. Look for machines designed with adaptability in mind, accommodating different steel grades effortlessly. This versatility not only broadens the spectrum of applications but also future-proofs your operations against evolving material requirements.

When considering customization options, envision a machine that goes beyond the conventional. The ability to tailor dimensions, thickness, and other parameters on the fly is a hallmark of a truly adaptable C channel roll forming machine. This flexibility ensures that your production aligns precisely with the unique specifications of diverse projects.

Lastly, in the pursuit of operational excellence, evaluate the forming speed and production capacity in granular detail. A nuanced understanding of these factors ensures that your chosen machine seamlessly integrates into your workflow, meeting project timelines with unwavering efficiency.

In the dynamic landscape of metal fabrication, where precision meets versatility, choosing a C channel roll forming machine is not just a selection—it’s a strategic investment in the future of your production capabilities.

Conclusion Extended:

Choosing the right C channel roll forming machine involves a meticulous consideration of key features and technical specifications. The machine’s compatibility with different materials, customization options, automation level, tooling design, and ease of installation and maintenance are pivotal factors. Additionally, delving into technical specifications such as the number of roll forming stations, power requirements, dimensions, material thickness range, and control system ensures a comprehensive evaluation.

Investing time and effort in understanding these aspects will undoubtedly lead to the selection of a C channel roll forming machine that aligns with your production needs, enhances efficiency, and contributes to the success of your metal fabrication projects. Whether you are involved in large-scale industrial applications or intricate civil engineering projects, a well-chosen roll forming machine sets the foundation for precision, productivity, and overall project success.