A C purlin machine is an essential tool in the construction and metalworking industries, enabling the production of C-shaped steel profiles used for structural purposes in buildings, roofs, and walls. These purlins, typically used in steel-framed construction, offer an efficient and cost-effective solution for creating load-bearing beams, trusses, and support structures. The versatility of this equipment lies in its ability to process various materials, each selected based on specific requirements such as strength, durability, cost, and environmental factors.

In this article, we will delve into the various materials that can be used with a C purlin machine. By understanding the benefits and characteristics of different materials, you will be better equipped to choose the right one for your construction or manufacturing needs.

1. Understanding C Purlin Machines

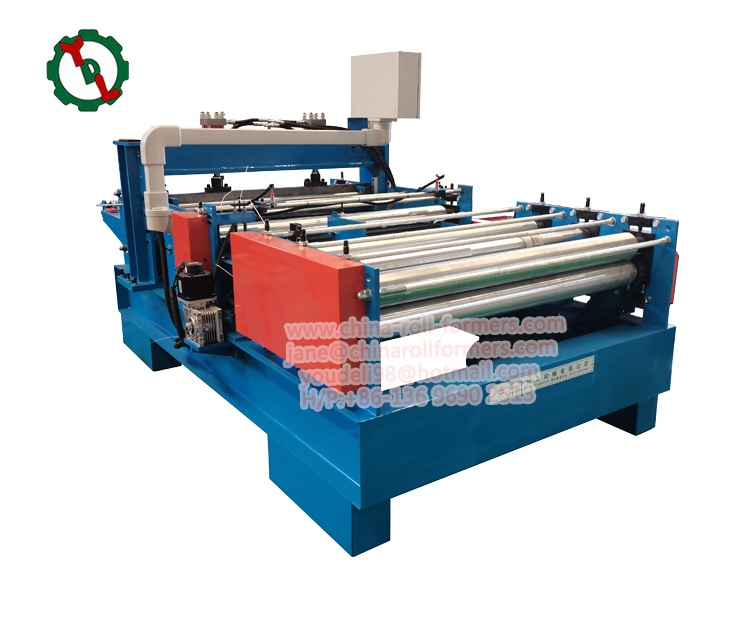

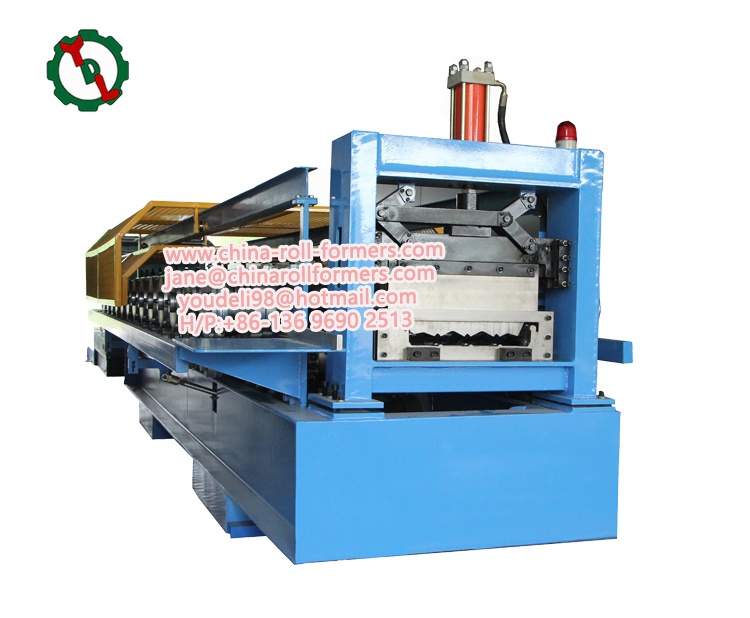

Before we dive into the materials, it’s important to understand the working principle behind a C purlin machine. A C purlin machine is a roll-forming machine designed to take flat metal sheets or coils and shape them into the C-section profile through a series of rollers. These rollers progressively bend and shape the material into the desired dimensions, followed by cutting, punching, and sometimes even coating, depending on the machine’s configuration.

C purlins are typically used as part of a larger structural system, supporting roofs and walls in industrial buildings, warehouses, agricultural structures, and more. The materials used in the production of C purlins directly influence the strength, durability, and overall cost-effectiveness of the final product.

2. Common Materials Used with a C Purlin Machine

A variety of materials can be processed by a C purlin machine. These materials differ in their physical properties, such as strength, corrosion resistance, and weight, making them suitable for different applications. Below are the most commonly used materials for C purlin production:

2.1. Steel

Steel is the most widely used material in C purlin production. It is strong, durable, and relatively affordable, making it ideal for use in a wide range of construction projects. Within the steel category, there are different types that can be processed by a C purlin machine:

- Carbon Steel: This is the most common type of steel used for manufacturing C purlins. Carbon steel is known for its high strength and ability to withstand heavy loads. It is cost-effective and suitable for general construction purposes, including agricultural and industrial buildings.Vorteile:

- High strength-to-weight ratio.

- Versatile and widely available.

- Relatively low cost compared to more specialized steels.

- Easy to weld and join with other steel components.

Anwendungen: Structural framing, roofing, and wall supports in industrial and commercial buildings.

- Verzinkter Stahl: Galvanized steel is carbon steel that has been coated with a layer of zinc. This coating helps protect the steel from rust and corrosion, making galvanized steel ideal for use in outdoor or exposed environments.Vorteile:

- Corrosion-resistant, making it ideal for use in areas with high humidity or coastal environments.

- Longer lifespan compared to uncoated steel.

- Requires less maintenance than non-galvanized steel.

Anwendungen: Roofing, wall cladding, and framing in areas exposed to weather conditions, such as agricultural buildings, warehouses, and industrial structures.

- Rostfreier Stahl: Stainless steel offers superior corrosion resistance compared to galvanized steel. It is often used for applications that require extra durability in harsh environments, such as chemical plants or coastal areas where saltwater can cause rapid deterioration of other materials.Vorteile:

- Exceptional resistance to corrosion, staining, and rust.

- Long-lasting and durable, even in highly corrosive environments.

- Aesthetic appeal due to its shiny, smooth surface.

Anwendungen: High-end construction, chemical plants, coastal buildings, and areas with extreme environmental conditions.

2.2. Aluminum

Aluminum is another popular material for C purlins, especially in applications where weight is a critical factor. Aluminum is known for its lightweight, corrosion-resistant properties, and ability to withstand harsh environmental conditions. Although it is generally not as strong as steel, its strength-to-weight ratio makes it an excellent choice for specific applications.

Vorteile:

- Lightweight, reducing the overall weight of the structure.

- Naturally corrosion-resistant, requiring little to no maintenance.

- Easy to handle, transport, and install due to its low density.

Anwendungen: Aerospace, transportation structures, lightweight buildings, and environments where corrosion resistance is important but weight reduction is a priority.

2.3. Pre-Painted Steel

Pre-painted steel, or color-coated steel, is a type of steel that has been coated with a layer of paint during manufacturing. This type of material combines the durability of steel with the aesthetic benefits of various colors and finishes. Pre-painted steel is often used for applications where the appearance of the final structure is a key consideration.

Vorteile:

- Offers a variety of colors and finishes to meet aesthetic requirements.

- Provides additional corrosion resistance due to the protective paint coating.

- Requires less maintenance because of the paint’s protective qualities.

Anwendungen: Residential, commercial, and industrial buildings where appearance is important, including roofing, wall panels, and facades.

2.4. High-Strength Low-Alloy (HSLA) Steel

HSLA steel is a type of carbon steel that contains small amounts of alloying elements such as copper, chromium, nickel, or molybdenum. These elements increase the steel’s strength without significantly increasing its weight. HSLA steel is used when higher strength is needed but lighter weight is still a priority.

Vorteile:

- High strength-to-weight ratio.

- Improved resistance to corrosion compared to standard carbon steel.

- It performs well under high-stress conditions, making it ideal for heavy-duty applications.

Anwendungen: Heavy-duty frames, large industrial structures, bridges, and other applications where high strength is required without excessive weight.

2.5. Galvalume Steel

Galvalume steel is a type of steel that is coated with a combination of aluminum and zinc. The dual coating provides the steel with excellent corrosion resistance, especially in environments where moisture and extreme weather conditions are common.

Vorteile:

- Excellent corrosion resistance, even in harsh environments.

- Long-lasting and durable, with a lifespan longer than traditional galvanized steel.

- Offers better heat resistance compared to regular galvanized steel.

Anwendungen: Roofing, agricultural buildings, and industrial construction, particularly in areas with high levels of moisture or extreme temperatures.

2.6. Copper

While not as common as steel and aluminum, copper is sometimes used in specialized applications where both durability and aesthetic appeal are important. Copper is highly resistant to corrosion and has an attractive appearance that is ideal for decorative purposes.

Vorteile:

- High resistance to corrosion and oxidation.

- Aesthetic appeal, as copper develops a patina over time.

- Durable in harsh environments.

Anwendungen: Decorative roofing and cladding, architectural features, and specialized construction in high-end commercial or residential buildings.

3. Choosing the Right Material for Your C Purlin Machine

Selecting the right material for your C purlin machine is crucial to ensuring the structural integrity, longevity, and efficiency of your purlins. Several factors, such as the application, environmental conditions, load requirements, and budget constraints, should guide your decision. Below are some key considerations when choosing the best material for use with your C purlin machine:

3.1. Environmental Conditions

If the purlins will be used in areas with high humidity, exposure to chemicals, or coastal environments, materials such as galvanized steel, stainless steel, or aluminum are ideal for use with a C purlin machine. These materials offer excellent corrosion resistance, ensuring that the purlins produced can withstand the elements over an extended period without significant deterioration. Choosing the right material for these conditions will increase the lifespan of the purlins and reduce maintenance costs.

3.2. Load Requirements

For structures that require higher load-bearing capacity, stronger materials such as carbon steel, HSLA steel, or thicker galvanized steel are preferable when working with your C purlin machine. These materials can handle the stress and weight demands of large industrial or commercial structures, ensuring that the purlins perform optimally under heavy loads and maintaining their integrity over time.

3.3. Weight Considerations

If weight is a concern—especially for projects involving temporary structures or lightweight buildings—aluminum or HSLA steel would be suitable options. These materials offer the necessary strength without significantly adding to the overall weight of the building. When used in the purlin production process, they provide a balance of structural support and ease of handling, ideal for projects requiring a lighter load-bearing solution.

3.4. Budget

Budget often plays a significant role in material selection. While stainless steel and aluminum provide superior performance and durability, they come at a higher cost. For more budget-conscious projects, galvanized steel or carbon steel are cost-effective alternatives that still offer a good balance of strength, durability, and affordability. Choosing the right material in line with your budget can help maximize your investment while ensuring the long-term performance of the purlins.

3.5. Aesthetic Needs

If the visual appearance of the structure is important, pre-painted steel or copper may be the best options. These materials offer a wide range of colors and finishes, allowing the structure to blend seamlessly with its surroundings or meet specific architectural requirements. Whether for aesthetic or functional purposes, these materials can help achieve a visually appealing outcome in any construction project.

4. Schlussfolgerung

C purlin machines are versatile tools that can process a wide variety of materials, each with its own advantages depending on the specific requirements of the project. Steel, aluminum, pre-painted steel, HSLA steel, and other materials can all be used to create durable, cost-effective, and reliable C purlins. By understanding the properties and benefits of each material, engineers and builders can select the right one for their needs, ensuring the long-term success and stability of the structure. Whether it’s for a large industrial building or a lightweight agricultural shed, choosing the right material for your C purlin machine is essential to achieving the desired balance of strength, cost, and performance.