Introduction:

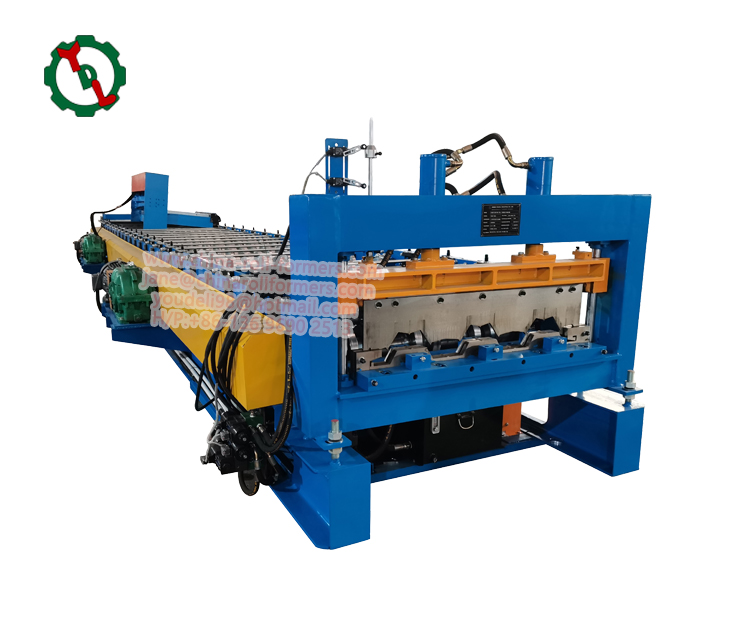

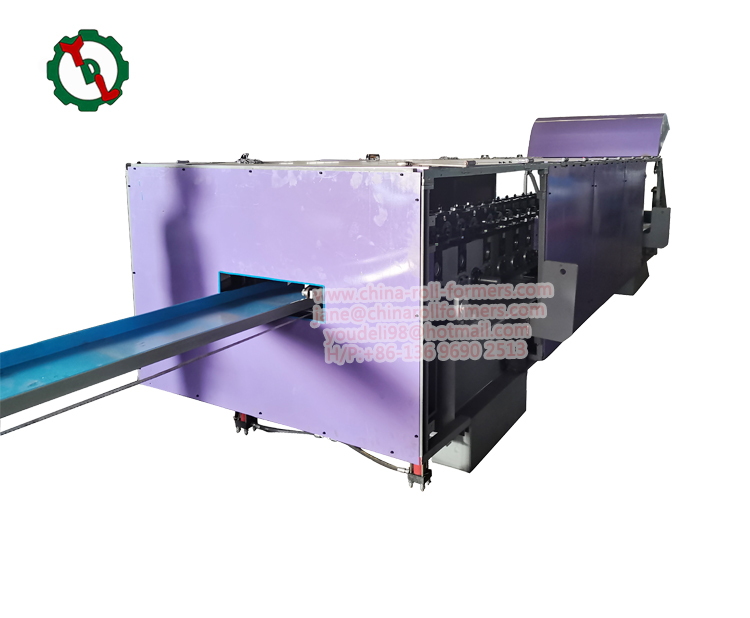

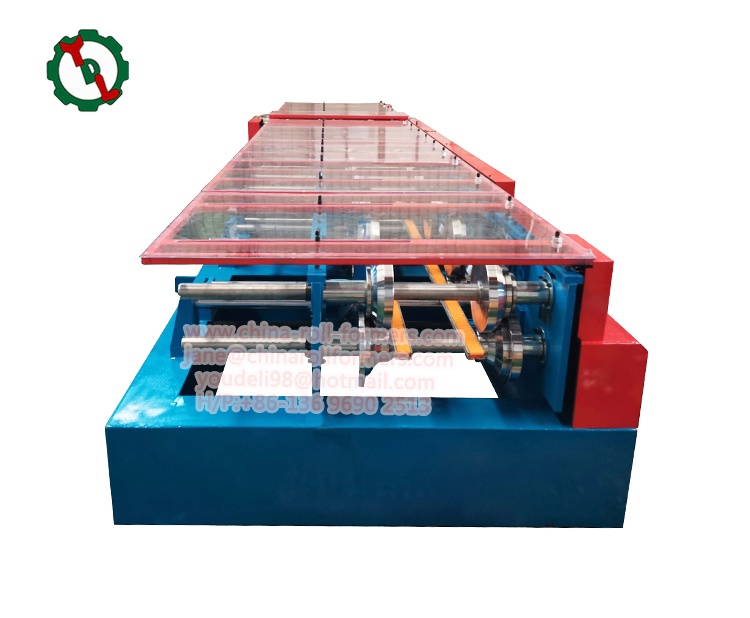

In the realm of modern construction, standing seam roofing has become synonymous with durability, aesthetics, and efficiency. At the heart of crafting precise standing seam roofs lies the standing seam profiling machine, a technological marvel designed to handle a diverse range of materials. This article delves into the intricacies of the typical materials that it can adeptly process, shedding light on the versatility that makes these machines indispensable in the roofing industry.

I. Metal Alloys:

One of the primary materials handled by standing seam profiling machines is various metal alloys. These machines are expertly engineered to shape and profile metals like aluminum, steel, and copper. The ability to handle different metal alloys ensures that roofing professionals have the flexibility to choose materials based on factors such as climate, aesthetics, and budget, without compromising on the precision of the standing seam profile.

- Aluminum:

Standing seam profiling machines excel in processing aluminum, a lightweight and corrosion-resistant metal. The machines maintain the integrity of aluminum panels, ensuring a seamless and durable standing seam roof. This is particularly valuable for projects where weight considerations, such as in aviation or coastal installations, come into play.

- Steel:

Robust and widely used in construction, steel is a common material for standing seam roofs. Profiling machines expertly form steel sheets into precise profiles, contributing to the structural strength and longevity of the roofing system. Steel’s availability and affordability make it a popular choice, and standing seam profiling machines play a crucial role in shaping it to meet project specifications.

- Copper:

For projects that prioritize aesthetics and require a material with natural corrosion resistance, copper is often the material of choice. Its delicately handle copper sheets, preserving their distinctive appearance while ensuring the creation of tight and secure seams. Copper roofs, when crafted with precision, can add a touch of elegance to diverse architectural styles.

II. Zinc:

Zinc is another material that stands out for its corrosion-resistant properties and distinctive appearance. Standing seam profiling machines are equipped to handle zinc sheets, offering roofing professionals the ability to create unique and visually appealing standing seam roofs. The malleability of zinc allows for intricate profiling, contributing to the creation of customized roofing solutions.

III. Painted and Coated Metals:

Standing seam profiling machines are not limited to natural metal finishes; they can proficiently handle painted and coated metals. These coatings serve dual purposes of enhancing aesthetics and providing additional protection against the elements. Profiling machines ensure that the coatings remain intact during the shaping process, resulting in a finished product that combines both style and durability.

IV. Composite Materials:

Advancements in construction technology have led to the development of composite materials that combine different elements to achieve specific properties. Standing seam profiling equipments are adaptable enough to work with composite materials, providing roofing professionals with options that offer a balance of strength, weight, and other desired characteristics. The precision of profiling ensures that the composite panels maintain their structural integrity.

V. Stainless Steel:

Known for its resistance to corrosion and staining, stainless steel is a material of choice in environments with demanding conditions. Standing seam profiling machines handle stainless steel sheets with precision, allowing for the creation of standing seam roofs that meet the highest standards of durability and hygiene. This makes stainless steel an ideal choice for applications in healthcare facilities, food processing plants, and other specialized settings.

VI. Pre-Painted Coils:

To streamline the roofing process and meet specific color requirements, standing seam profiling machines can efficiently process pre-painted coils. These coils come with factory-applied finishes, and profiling machines carefully shape them into standing seam panels without compromising the integrity of the paint. This capability enhances efficiency in construction projects where time and consistency are crucial factors.

VII. Galvanized Steel:

Galvanized steel, coated with a layer of zinc for added protection against corrosion, is a material well-suited for standing seam roofs. Profiling machines handle galvanized steel sheets, ensuring that the zinc coating remains intact during the shaping process. This results in standing seam roofs that not only exhibit structural strength but also have enhanced resistance to rust and corrosion.

VIII. Titanium:

In niche applications where lightweight strength and exceptional corrosion resistance are paramount, titanium becomes a material of interest. Standing seam profiling machines, with their precision and adaptability, can process titanium sheets. While less common due to its higher cost, titanium offers a unique set of properties that make it desirable for specific architectural and industrial projects.

IX. Considerations for Material Thickness:

Standing seam profiling machines are designed to handle a range of material thicknesses, allowing for versatility in roofing projects. Whether working with thin gauges for residential applications or thicker gauges for commercial and industrial projects, these machines can be adjusted to achieve the desired seam profiles without compromising the material’s structural integrity.

X. Customization and Precision:

One of the defining features of standing seam profiling equipments is their ability to deliver customization and precision. Roofing professionals can achieve specific seam profiles, widths, and dimensions based on project requirements. This customization extends to the choice of materials, empowering architects and builders to bring their design visions to life with meticulous accuracy.

XI. Embracing Lightweight Solutions:

Standing seam profiling machines showcase impressive versatility in handling lightweight materials, notably aluminum and zinc. Despite their weightlessness, these materials offer exceptional strength and durability. The machines intricately shape these lightweight panels into precise profiles, ensuring structural integrity. This feature proves advantageous in roofing projects where minimizing weight is a top priority.

XII. Advancing Thermal Efficiency:

Amid a growing emphasis on energy efficiency in construction, standing seam profiling machines play a pivotal role in working with materials designed for optimal thermal performance. Insulated metal panels, featuring a core material for thermal insulation sandwiched between metal layers, are expertly shaped by profiling machines. This contribution enhances building energy efficiency and aligns with sustainable construction practices.

XIII. Conquering External Challenges:

The demanding external environments necessitate roofing materials capable of withstanding diverse weather conditions. Standing seam profiling machines excel in handling weather-resistant materials, including coated metals with specialized finishes engineered to endure harsh climates. Whether facing intense sunlight, heavy rainfall, or extreme temperatures, these roofing materials maintain their integrity, ensuring long-lasting protection to structures.

Conclusion:

The versatility of standing seam profiling machines in handling a spectrum of materials underscores their pivotal role in the roofing industry. From traditional metals like aluminum and steel to innovative materials like titanium and composite panels, these machines empower roofing professionals to create durable, aesthetically pleasing standing seam roofs. The precision, adaptability, and customization offered by standing seam profiling equipments position them as indispensable tools in the construction of roofs that marry functionality with architectural excellence.