Les Machine à panneaux sandwichs en PU is a critical piece of equipment in the manufacturing process of polyurethane (PU) sandwich panels, which are widely used in the construction, insulation, and cold storage industries. These panels are valued for their excellent thermal insulation properties, durability, and lightweight design. As demand for energy-efficient building materials continues to grow, the PU sandwich panel machine plays an increasingly important role in producing these panels at scale.

This article provides an in-depth explanation of how a PU sandwich panel machine works, covering the key components, processes, and technologies involved in manufacturing PU sandwich panels. It will also discuss the benefits and applications of these panels, as well as the role of automation and precision in modern PU sandwich panel production.

1. Introduction to PU Sandwich Panels

Before delving into the working of the machine, it’s important to understand what PU sandwich panels are and why they are so widely used. A PU sandwich panel consists of three layers: two outer layers, typically made of metal (such as steel or aluminum), and a core layer made of polyurethane foam. The core layer provides insulation properties, while the outer layers offer structural strength and protection from external elements.

The polyurethane foam core is known for its superior thermal insulation performance, fire resistance, and soundproofing qualities. These panels are used in a wide range of applications, including the construction of warehouses, cold storage rooms, roofs, walls, and even temporary structures such as portable offices.

2. The Components of a PU Sandwich Panel Machine

A PU sandwich panel machine is composed of several key components that work together to produce high-quality sandwich panels efficiently and consistently. The primary components of a PU sandwich panel machine include:

2.1. Dérouleur

The uncoiler is the component that holds and unwinds the metal coils used for the outer layers of the sandwich panel. The metal sheets are typically made of galvanized steel, aluminum, or other materials that are corrosion-resistant and durable. The uncoiler ensures that the metal sheets are fed smoothly into the production line without tangling or damaging the material.

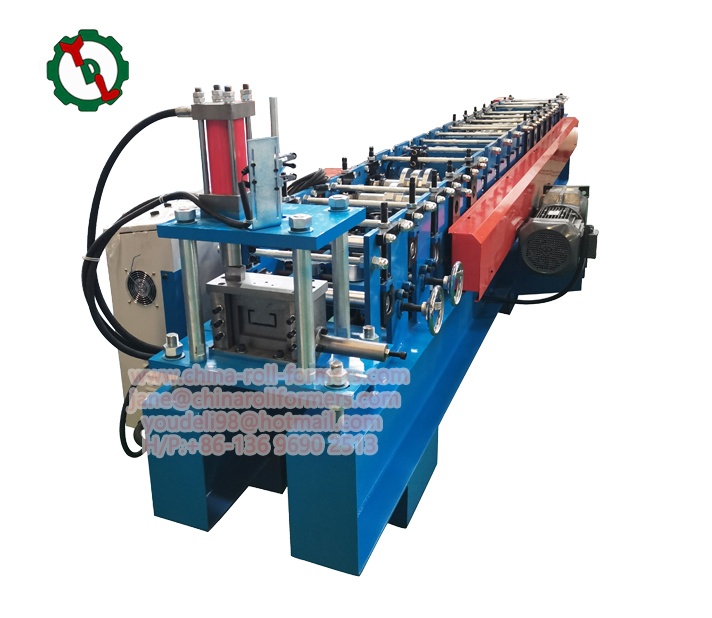

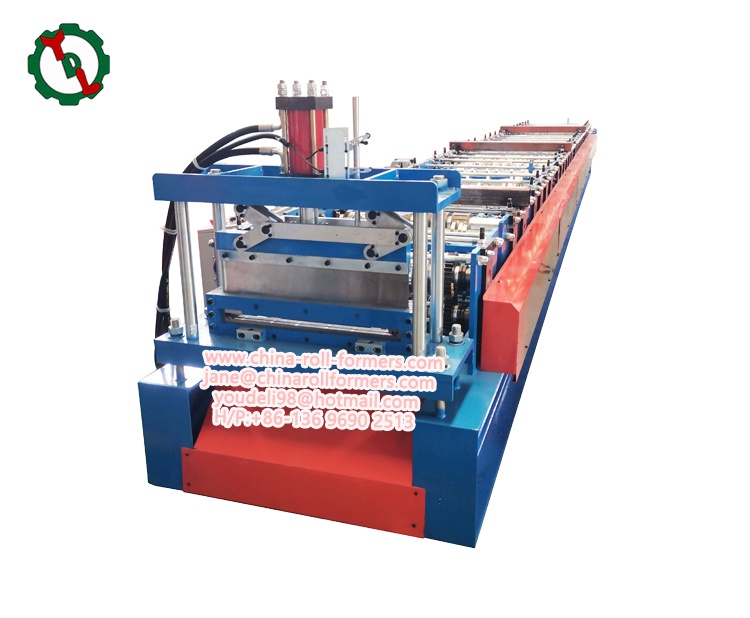

2.2. Machine à former des rouleaux

The roll forming machine shapes the metal sheets into the desired profiles for the outer layers of the sandwich panel. This process involves passing the metal sheets through a series of rollers that gradually bend and form the sheets into specific shapes, such as corrugated or flat profiles. The roll forming process is crucial because the profile of the outer layer influences the panel’s strength, thermal insulation, and aesthetic appearance.

2.3. Polyurethane Foam System

The heart of the PU sandwich panel machine is the polyurethane foam system, which mixes and dispenses the foam core material into the sandwich panel. The system consists of several parts:

- Polyol and Isocyanate Tanks: These tanks hold the two main chemicals that are mixed to form polyurethane foam: polyol and isocyanate. When mixed, these chemicals react to form a foam that expands and hardens, providing thermal insulation.

- Mixing and Dispensing System: The polyol and isocyanate are pumped into a high-speed mixer, where they are combined and blended. The resulting foam mixture is then dispensed onto the lower metal sheet (the bottom layer of the panel). This system must be highly accurate to ensure that the foam is dispensed evenly and with the correct density.

- Heating and Curing Section: After the foam is applied, it begins to expand and cure. The machine usually includes a heating or curing section to accelerate this process and ensure that the foam reaches its optimal density and insulation properties. Some machines include an infrared or hot air system to speed up curing.

2.4. Laminating Station

Once the polyurethane foam has been dispensed and cured, the top metal sheet (the second outer layer) is fed over the foam. The laminating station ensures that the top metal sheet is perfectly aligned with the foam and the bottom sheet. This section uses high pressure and rollers to bond the layers together. The result is a fully formed sandwich panel.

2.5. Cutting and Stacking Section

After the sandwich panel has been laminated, it is moved to the cutting section, where it is cut into the desired lengths based on the production specifications. The cutting is typically done using an automatic cutting system that uses a rotating blade or a hydraulic cutter. Once cut, the panels are stacked for further inspection, packaging, and shipping.

2.6. Système de contrôle

Modern PU sandwich panel machines are equipped with advanced control systems that monitor and regulate the entire production process. These control systems include sensors, touch-screen interfaces, and programmable logic controllers (PLCs) that allow operators to adjust settings, track production speeds, and ensure that the panels meet quality standards. The control system ensures that the entire process runs smoothly, from material feeding to cutting.

3. The Production Process of a PU Sandwich Panel

The production of PU sandwich panels involves several key steps, which are automated and synchronized to ensure the consistent quality of the final product. Below is a detailed overview of the typical production process:

3.1. Feeding of Materials

The process begins with the feeding of the metal sheets into the PU sandwich panel machine. The uncoiler unwinds the metal coils and sends them into the roll forming machine. Simultaneously, the polyol and isocyanate are pumped into the mixing system, where they are prepared for foam production.

3.2. Roll Forming the Metal Sheets

As the metal sheets pass through the roll forming machine, they are gradually shaped into the desired profile. The process can be adjusted to create different profiles, such as flat panels or corrugated ones, depending on the requirements of the final product. This step ensures that the outer layers of the panel are formed with precise dimensions and strength.

3.3. Foam Injection

Once the metal sheets are ready, the foam dispensing system in the PU sandwich panel machine applies a thin layer of the polyurethane foam mixture onto the surface of the bottom metal sheet. The foam mixture expands as it is dispensed, filling the gap between the two metal sheets. The precise control of the foam’s density and distribution is essential to ensuring the thermal performance and strength of the sandwich panel.

3.4. Laminating and Bonding

The top metal sheet is then applied to the foam and bottom sheet, and the laminating station applies pressure to bond the layers together. This process ensures that the foam is securely trapped between the two metal layers, creating a strong, durable, and thermally efficient panel.

3.5. Curing and Setting

The foam undergoes a curing process, either through natural curing or with the help of heating systems. During this stage, the foam solidifies and reaches its final density, ensuring the panel’s strength and insulation properties.

3.6. Cutting the Panels

Once the sandwich panels have been laminated and cured, they are passed through an automatic cutting system integrated into the PU sandwich panel machine, which cuts the panels to the desired length. The cutting process is highly accurate and ensures that the final panels meet the required dimensions.

3.7. Stacking and Quality Inspection

The finished panels are then stacked in preparation for shipment. Some PU sandwich panel machines are equipped with automated stacking systems that help organize the panels efficiently. During this stage, quality control inspections are often conducted to ensure that the panels meet the required specifications in terms of dimensions, foam density, and adhesion strength.

4. Conclusion

The PU sandwich panel machine plays a crucial role in the production of high-performance sandwich panels that are widely used in construction and insulation applications. The machine operates through a series of coordinated steps, including material feeding, roll forming, foam injection, laminating, curing, cutting, and quality control. Advanced automation and precision are essential for ensuring that each panel meets the necessary standards for thermal insulation, durability, and strength.

With the increasing demand for energy-efficient, durable, and cost-effective building materials, PU sandwich panels are expected to continue to play a significant role in modern construction. The PU sandwich panel machine will remain at the forefront of this industry, helping to meet the growing demand for high-quality panels that offer superior insulation, strength, and versatility.