| 購入数量 | 1セット |

| ポート | 中国 |

| 支払条件 | L/C、T/T |

| フォブ | お問い合わせ価格 |

| 認証だ: | CE、ISO |

| コンディション | 新しい |

| カスタマイズされた: | カスタマイズ |

| 自動グレード: | 自動 |

| トランスミッション | 駆動用モーターとチェーン |

| 移動手段 | 海上コンテナ |

| パッキング: | 輸出基準 |

| 納期: | 60日 |

1

会社概要

2

商品説明

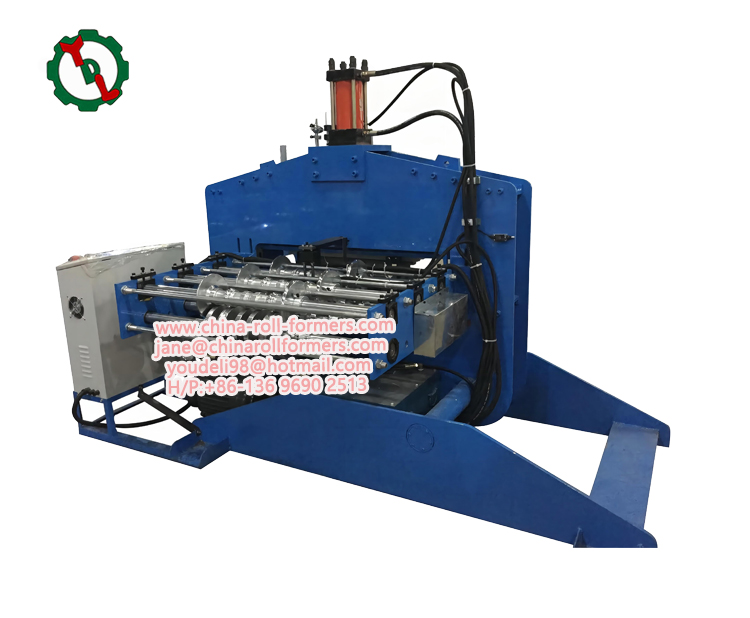

| モデルNO. | YX38-290-530 |

| サイズ | 2500*1400*1300mm |

| 重量 | 1800KGS |

| 電圧 | 220V/60HZ/3PH |

| 成形ステップ | 9steps |

| Height of Roofing | 38mm |

| Effective Width of Roofing | 290mm-530mm |

| 素材幅 | 394mm-634mm |

| Forming Aluminum Thickness | 0.6-1.2mm |

| Forming Steel Thickness | 0.5-1.0mm |

| 寛容 | ±2mm |

| 素材 | GI, PPGI,PPGL, Aluminum, Stainless Steel |

| PLC プログラム制御システム | オリジナル台湾デルタ/シーメンス/シュナイダー |

| アフターサービス | オンライン24時間/フィールドサポート |

| サービス | 機械の設置にエンジニアを派遣 |

| シャフトの材質 | 高品位45#鍛鋼 |

3

商品説明

Roller material: 45# steel with machining—Heat Treatment—Fine Machining— Polishing—Plated Hard Chrome—Polishing;

How long it takes to produce a roof and which workers are needed

The time it takes to produce a roof and the type of workers required can be affected by a number of factors, including the size, structure, materials and construction conditions of the roof. Here is a general overview:

1、production time

- Design planning: Before starting production, it is usually necessary to carry out detailed design planning, including the size, shape, structure and material selection of the roof. The timing of this phase depends on the complexity of the design and the number of modifications required.

- Material preparation: Once the design is completed, the required materials need to be prepared. This includes buying steel, waterproofing, insulation, etc., and may take a certain amount of time to transport and store.

- Production and installation: The production and installation of the roof is the most time-consuming stage. For the steel structure roof, the steel skeleton needs to be made and installed, and waterproof treatment and insulation layer need to be laid. The timing of this phase depends on the size of the roof, the complexity of the structure and the efficiency of the construction team.

Overall, the time it takes to produce a roof can vary from weeks to months, depending on a combination of the above factors.

2、 Required workers

- Construction workers: Construction workers play a vital role in roof construction. They set up scaffolding, move materials, install steel frames and roof tiles.

- Welders: In the production and installation process of steel structure roof, welders are essential. They are responsible for the precise cutting, splicing and welding of the steel to ensure that the entire structure is strong and stable.

- Electrician: Electrician in the roof construction is mainly responsible for the installation of electrical facilities, such as wires, lamps, sockets and so on. They also need to ensure that these facilities are coordinated with the safety and waterproofing of the roof structure.

- Technical workers: technical workers are responsible for a variety of accurate measurement, cutting and splicing work in roof construction. They also need to perform maintenance and maintenance on the roof structure to ensure the stability and safety of the entire structure.

In addition, depending on the needs of the project, other types of professionals may be required, such as safety supervisors, quality inspectors, etc.

To sum up, the time it takes to produce a roof depends on a variety of factors, and the types of workers required mainly include construction workers, welders, electricians and technicians. In actual construction, reasonable arrangements and deployments should be made according to specific needs and conditions.

The materials required mainly include the following aspects:

1、the main structural materials

- Steel: used to manufacture the main frame, support structure and transmission parts of the machine. The steel needs to have good strength and rigidity to ensure the stability and durability of the machine. For example, the main frame of the machine may be welded with steel plates and stress-relieved to improve its overall strength and stability.

- High quality roller materials: such as S45C steel, which is heat treated and hard chrome coated on the surface, for forming and pressing sheet metal.The selection and treatment of roller materials is crucial to ensure the quality and accuracy of the product.

2、transmission and control system materials

- Motor: Provide the power required for the operation of the machine.The selection and configuration of the motor should be determined according to the power requirements and operating efficiency of the machine.

- Transmission parts: such as gear box, chain and drive shaft, etc., used to transfer the power of the motor to each working part.These parts need to have good wear resistance and reliability to ensure the stable operation of the machine.

- Control system: PLC (Programmable logic controller) is usually used for control to improve the degree of automation and operation efficiency of the machine.PLC brands may include Panasonic, Mitsubishi, etc.

3、forming and cutting materials

- Molding mold: customized according to the desired shape and specifications of the roof panel, used to press the metal sheet to form.The design and manufacturing accuracy of the molding mold is crucial to ensure the molding quality of the product.

- Cutting blade: used to cut the metal sheet after forming.Cutting blades are usually made of high-strength materials such as Cr12 to ensure the accuracy and efficiency of cutting.

- Other auxiliary materials

- Hydraulic oil: used for the operation and transmission of hydraulic systems.The choice of hydraulic oil should be determined according to the working pressure and temperature range of the system.

- Lubricant: used to reduce friction and wear during the operation of the machine, improve the operating efficiency and life of the machine.

- Electrical components: such as wires, cables, switches, indicators, etc., used for electrical connection and control of the machine.

4

証明書

鋼鉄の5つの特徴:

1、共通の「数」の言葉の母屋の構造は、効果的に滴り露現象によって形作られる温室の温度の相違を取扱う、効果的に冬の露の問題の温室を取扱うことができる。

2 の熱いすくいの電流を通された鋼板材料、よい耐食性、より長い生命、15 年以下の正常な耐用年数。

3、外観は美しく現代的で、全体的な構造強度は大きく、耐力は以前の鋼管構造よりはるかに大きいことができる。

4、ステレオタイプ機器の生産のすべての温室の骨格の選択は、便利なデバイスは、はんだ接合部は、時間が錆びることはありません。

5、柱のないスケルトンセンターのスパン内で10メートル、大幅に農耕面積を増やし、労働力を節約し、効率を高める。

強みを選択する

- 経験私たちは15年の業界経験と専門知識を持っており、高品質のサービスを提供しています。

- 効率的な生産能力:YOUDELlは先進的な生産設備と完璧な生産プロセスを持っています。 私達は現代的な生産管理方法を採用し、あらゆる生産の連結が最大限に活用されることを保障し、それにより生産の効率および質を改善します。

- 革新的な思考私たちは革新的な思考と先進的な科学技術手段を持ち、お客様により良いソリューションを提供します。

- 専門チームYOUDELlには、効率的で信頼性の高いインテリジェントな機器の開発に専念する専門の研究開発チームがあります。私達は最先端の技術およびプロセスを使用します、私達にフル レンジのサービスそしてサポートを提供してもいい専門のチームがあります。

- 質の高いサービス:YOUDELlcompanyは常に顧客中心のサービス理念を堅持しています。私達は前販売、販売、販売後のサービスのフル レンジを時機を得た助けおよびサポートの過程においてプロダクトの購入そして使用の顧客を保障するために提供します。

- リーズナブルな価格お客様の投資を価値あるものにするため、リーズナブルな価格と料金をご提供いたします。

- 誠実な経営私達は完全性の管理の概念を付着し、顧客との長期にわたる安定した協同関係を確立できます。

- 良いブランドイメージ:YOUDELlは屋根葺き機械と関連設備の分野で良いブランドイメージと評判を持っています。私たちは製品の品質とサービスを重視し、顧客の信頼と認識を獲得し、市場で優れたイメージを設定します。

5

貨物の積み込み

6

当社を選ぶ理由

- ご要望に応じて、あらゆる種類のロール成形機を設計・製作いたします。

- This is a very dependable piece of machinery. We have more than 15years of experience.

- This kind of equipment has the best quality and price. It is easy to use and provides precise measurement.Depending on the requirements of the clients, we can create special devices.

- 4.We may provide technical support, production, installation, debugging, and maintenance services to all customers.5.

- 私たちは、お客様との長期ビジネスを確立されています。私達のプロダクトの何れかのモデルに興味がある場合は、お問い合わせは、自由にしてくださいを参照してください。

7

サンプル室

よくあるご質問

01.自分に最適なマシンを選ぶには?

1. A machine doesn’t only show a few images to demonstrate its capabilities

2. A machine ought to have images and videos of a comprehensive production and assemblysystem. Making sure a company has a thorough after-sales service system is essential whenselecting one with a factory.

02.How can we ensure quality, then?

Before mass manufacturing, there is always a pre-production sample; before shipment, there isalways a final inspection.

03.どのような製品を販売していますか?

Roof tile Roll Forming Equipment, Wall Roll Former, Tile Forming Equipment, and C Z-PurlinForming Equipment.

04.Do you offer post-purchase support?

With 15 years of production expertise, the strength to ensure, product quality is paramount andservice is the biggest after-sales benefit.

05.見積もりを依頼するには?

1.寸法図と厚さを教えてください。

2. Please specify in advance if you have any requirements for manufacturing speed, power.voltage, or brand.

3. lf you don’t have your own outline drawing, we can suggest various models based on what istypical in your area.