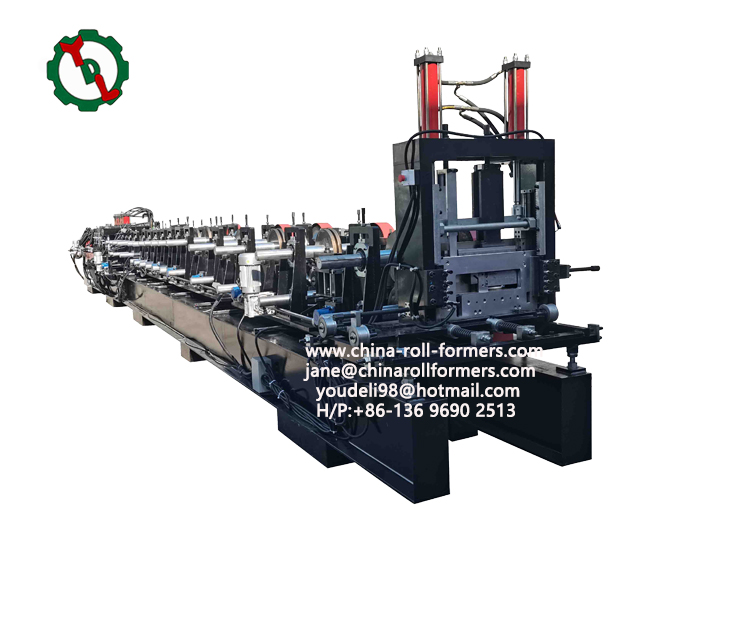

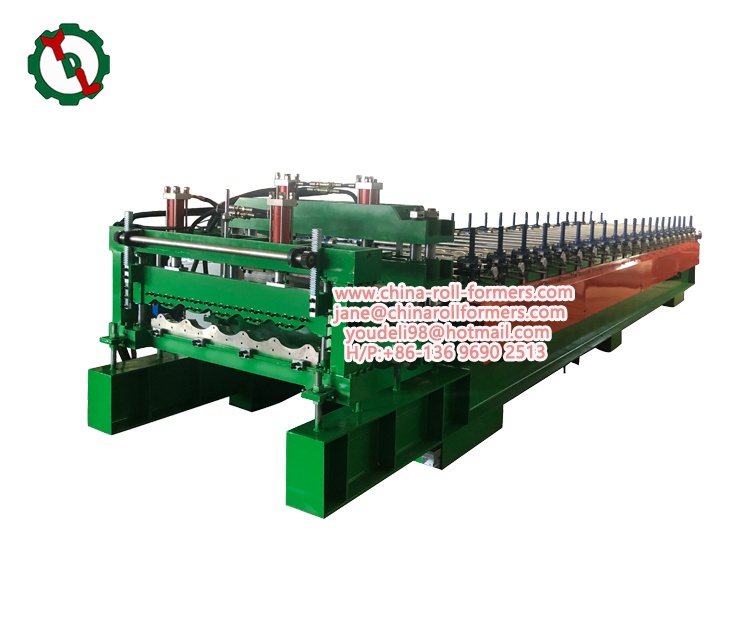

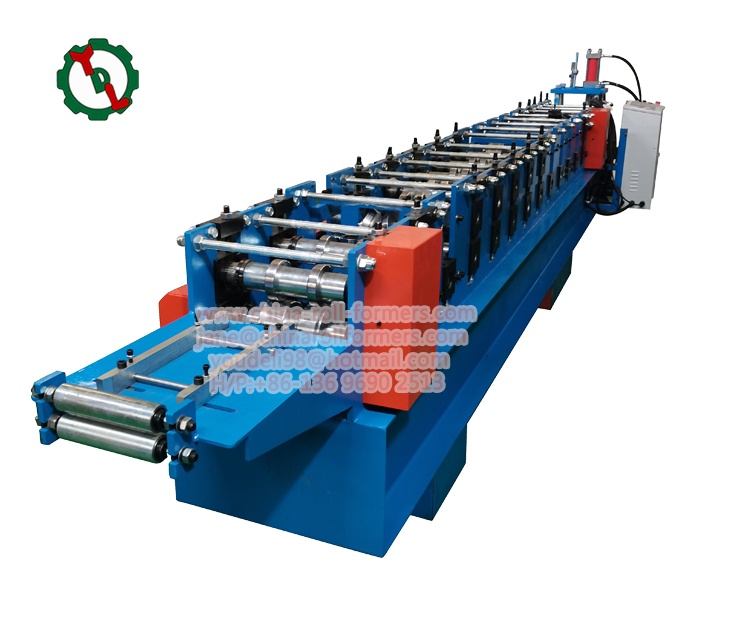

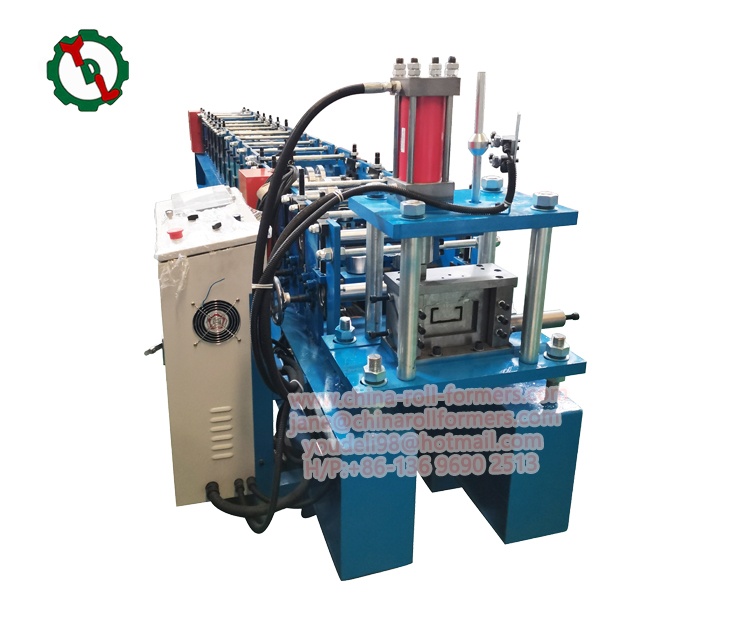

Cチャンネル製造機 are critical in many industries due to their ability to produce versatile C-shaped steel profiles used in construction, infrastructure, and manufacturing. These machines are highly efficient in fabricating C channels from steel, aluminum, or other metals, with variations in size, thickness, and length. The C channels produced have structural properties that make them integral to numerous industries where strength, rigidity, and durability are required.

In this article, we will explore the key industries that rely on C channel making machines, highlighting their applications, benefits, and the role of C channels in enhancing performance across sectors.

1. Construction Industry

The construction industry is one of the primary consumers of C channel making machines due to the extensive use of steel and aluminum channels in building and structural applications. C channels serve as essential load-bearing components in both residential and commercial construction projects. Their strength, combined with their lightweight nature, makes them ideal for framing, bracing, and reinforcing various building elements.

Key Applications in Construction:

- Framing: C channels are used for wall framing in structures, especially in areas where lightweight but sturdy material is required.

- Roof Support: In commercial and industrial buildings, C channels are often used to support roofing systems, providing the necessary strength to bear loads while keeping weight to a minimum.

- Bracing: C channels act as lateral bracing elements, enhancing structural stability in bridges, towers, and multi-story buildings.

- Door and Window Frames: C channels are commonly used for framing doors and windows, where precision and strength are critical for alignment and longevity.

The construction sector values the adaptability of C channel making machines, as they can produce channels in various sizes and thicknesses to meet the diverse needs of different projects. Additionally, these machines offer customization, ensuring that builders can create C channels that precisely match the specifications of their designs.

2. 自動車産業

The automotive industry has increasingly incorporated C channel making machines in the production of various vehicle components. The need for lightweight but durable materials in modern automotive design has made C channels a popular choice in the fabrication of chassis and body frames. C channels provide the structural integrity necessary for ensuring safety and performance without significantly increasing the vehicle’s weight.

Key Applications in the Automotive Sector:

- Chassis Construction: C channels are frequently used in vehicle chassis, providing the necessary strength and stiffness to support the vehicle’s frame while withstanding dynamic forces.

- Body Frame Components: In both passenger cars and commercial vehicles, C channels are used in the construction of door frames, window reinforcements, and bumper structures.

- Trailer Frames: For heavy-duty trailers and truck beds, C channels offer the required structural support, enabling these components to carry heavy loads safely and reliably.

Automotive manufacturers benefit from C channel making machines’ ability to produce precise, high-quality profiles that meet stringent industry standards. Additionally, these machines’ speed and efficiency allow for large-scale production, ensuring that manufacturers can keep up with the high demand for automotive components.

3. Infrastructure and Civil Engineering

Infrastructure projects, including the construction of bridges, tunnels, highways, and railways, require materials that provide strength, durability, and resistance to environmental factors. C channel making machines play a crucial role in supplying the steel channels needed for such projects, which are integral to supporting long spans, providing stability, and ensuring the longevity of critical infrastructure.

Key Applications in Infrastructure:

- Bridges and Overpasses: C channels are used in the structural framework of bridges and overpasses, where their high load-bearing capacity and resistance to deformation are vital.

- Railway Tracks: In the railway sector, C channels are utilized for track support systems and as reinforcement in rail infrastructure.

- Tunnels: C channels are employed in tunnel construction, particularly in reinforcing tunnel walls and ceilings, ensuring they can withstand both the weight of the earth above and the forces of passing vehicles or trains.

The durability of steel C channels, particularly when treated for corrosion resistance, makes them ideal for use in environments exposed to harsh weather conditions and fluctuating temperatures. Civil engineers depend on C channel making machines to deliver consistent, high-performance profiles that enhance the resilience and stability of critical infrastructure.

4. Aerospace Industry

In the aerospace industry, materials must meet rigorous performance standards to ensure safety, weight efficiency, and resistance to extreme conditions. While this sector traditionally uses materials like aluminum and titanium, C channels are still essential components in aircraft structures, where they provide support without significantly increasing the weight of the aircraft.

Key Applications in Aerospace:

- Aircraft Frames: C channels are incorporated into the construction of fuselage frames, wing spars, and other critical structural elements of aircraft.

- Internal Structures: Inside the aircraft, C channels are used to support seating, storage compartments, and electronic enclosures, where precision and strength are necessary for both safety and functionality.

- Spacecraft and Satellites: C channels also find application in the aerospace industry’s cutting-edge areas, such as spacecraft and satellite construction. Their lightweight and rigid nature make them ideal for handling the stresses experienced during launch and space travel.

Aerospace engineers rely on C channel making machines for producing high-precision components that meet the exacting requirements of the industry. These machines’ ability to work with different metals and produce customized profiles ensures that manufacturers can meet both performance and safety standards.

5. Manufacturing Industry

The manufacturing industry employs C channels in various machines, equipment, and assembly lines. C channel making machines are indispensable in producing the metal profiles required for supporting conveyor systems, robotic arms, machine housings, and production lines. Their strength, combined with their ease of integration, makes them vital to maintaining efficiency and safety in manufacturing environments.

Key Applications in Manufacturing:

- Conveyor Systems: C channels provide the structural framework for conveyor belts and automated material handling systems, where precision and load-bearing capacity are essential.

- Machinery Frames: Heavy industrial machinery often uses C channels in its frame construction, allowing for the machine to maintain its shape and function under stress.

- Shelving and Storage: In warehouses and manufacturing plants, C channels are used to construct shelving units and storage systems, where their strength ensures safe storage of heavy materials and equipment.

The versatility of C channels in manufacturing makes them a cost-effective solution, reducing the need for frequent maintenance or replacement of parts. Manufacturers benefit from C channel making machines’ ability to quickly produce high volumes of components that can be integrated into their production processes.

6. Energy Industry

The energy sector, particularly in oil, gas, and renewable energy, requires materials capable of withstanding extreme conditions, including high pressures, temperatures, and exposure to corrosive substances. C channels, fabricated by C channel making machines, are extensively used in pipelines, offshore platforms, and power plants for structural support and reinforcement.

Key Applications in the Energy Sector:

- Oil and Gas Platforms: In offshore drilling and production platforms, C channels provide structural support for pipelines, safety walkways, and equipment mounting.

- Solar Panel Mounting Systems: Renewable energy projects, especially solar farms, utilize C channels to support solar panels, ensuring they remain securely positioned in varying weather conditions.

- Wind Turbines: The internal structures of wind turbines often incorporate C channels to support the nacelle, blade mounts, and maintenance platforms.

The ability of C channel making machines to produce robust, corrosion-resistant profiles is critical in energy applications, where failure could result in environmental hazards or significant financial losses.

結論

C channel making machines are a cornerstone in multiple industries due to their ability to produce high-quality, customized C channels that meet the demands of diverse applications. From construction and automotive manufacturing to aerospace and energy sectors, these machines deliver reliable performance and enable manufacturers to enhance their products’ strength, durability, and efficiency. By investing in C channel making machines, industries ensure they have the flexibility and capacity to meet evolving market needs while maintaining the highest standards of quality and safety.