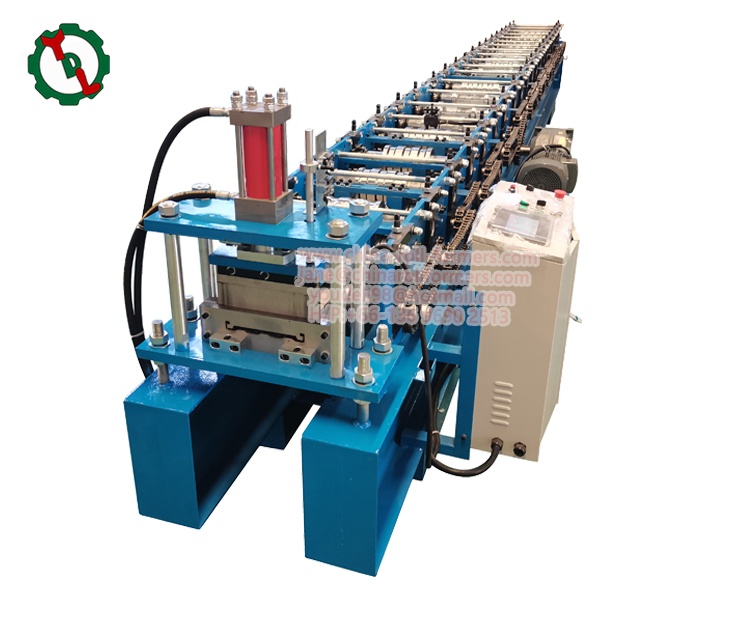

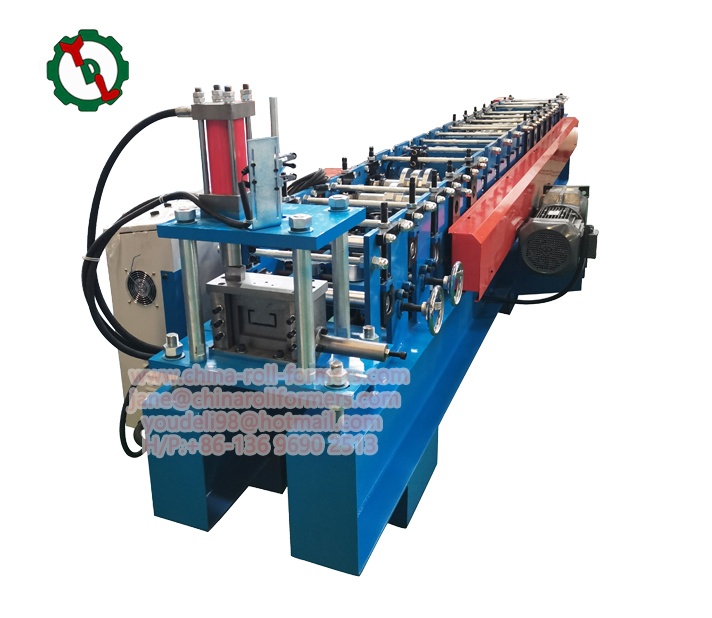

- 10 Fascia Board Roll Forming Machine

High-quality components and cutting-edge technology are used to create our fascia board roll forming machine, ensuring top performance. It allows you to quickly and efficiently make high-quality fascia boards that satisfy your clients' expectations thanks to its fully automated technology.

This machine can make fascia boards in a variety of lengths and sizes, making it appropriate for a range of roofing jobs. Anyone may use it with lttle training because to its straightforward UI.

Our Fascia Board Roll Forming Machine is also strong and requires lttle upkeep, making it a long-term investment for your company.