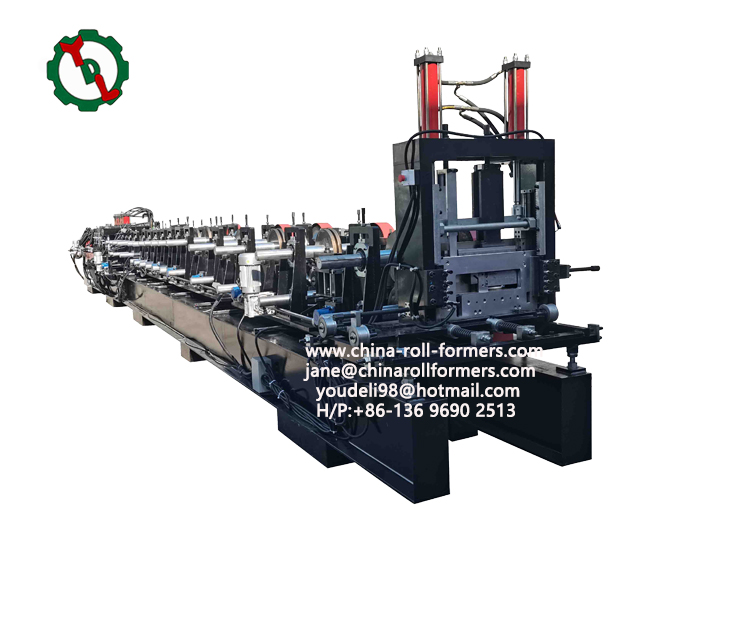

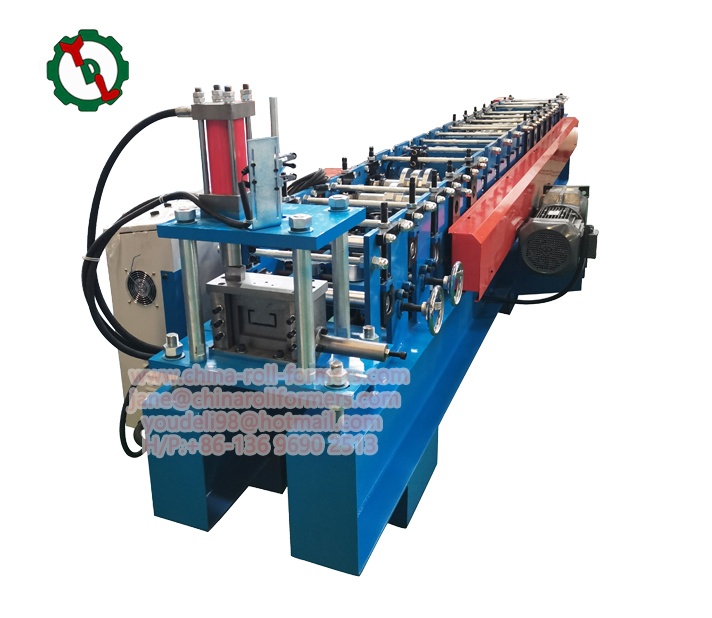

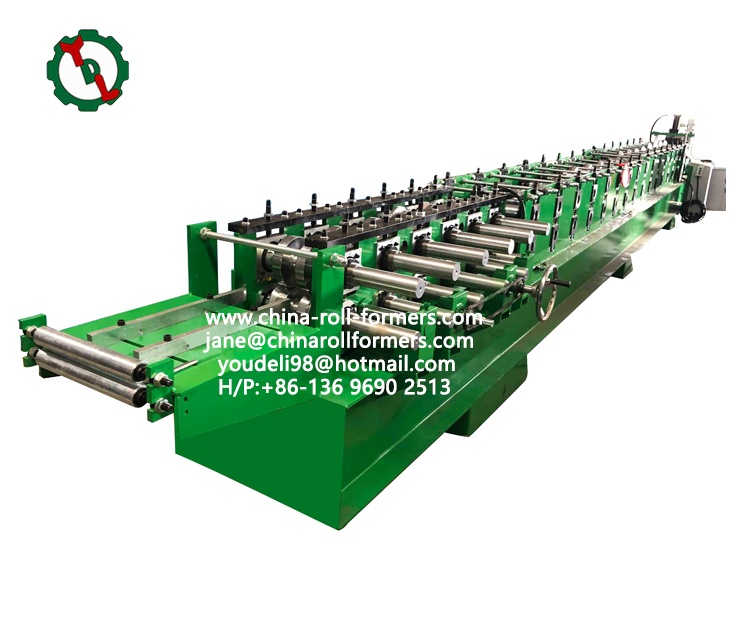

A brand-new, fully automatic interchanged steel frame purlin roll forming device has just been created, and it's poised to transform the building sector. With astounding speed and accuracy, this machine is able to produce high-quality purlins in a range of sizes and shapes, including C, Z, and U profiles.

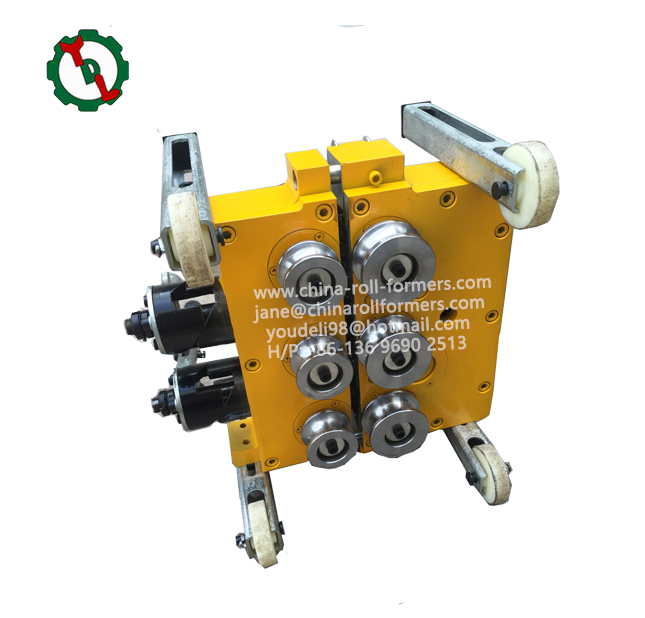

This machine's automatic interchanging mechanism, which enables quick and simple changeover between various profile forms, is one of its primary advantages. By doing this, purlins are produced consistently and precisely while also saving time and effort.

This machine's digital control system, which lets users to set and modify several parameters like cutting length, hole distance, and molding speed, is another benefit. In order to protect its users, the device also contains a safety mechanism that detects abnormal situations and shuts down the operation immediately. This device can be used in a broad variety of settings, including industrial facilities, infrastructural projects, and residential and commercial buildings. This machine is anticipated to lower building costs and raise the caliber of finished goods by offering a more effective and dependable purlin production solution.