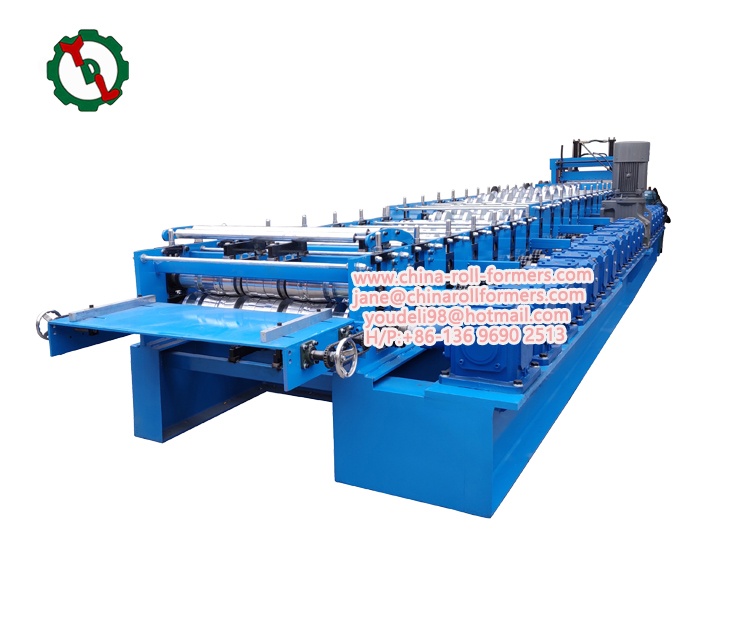

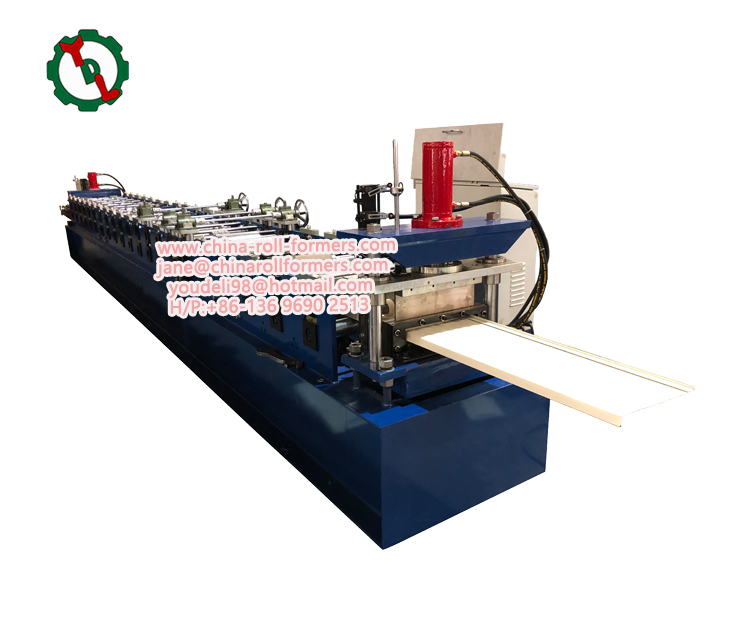

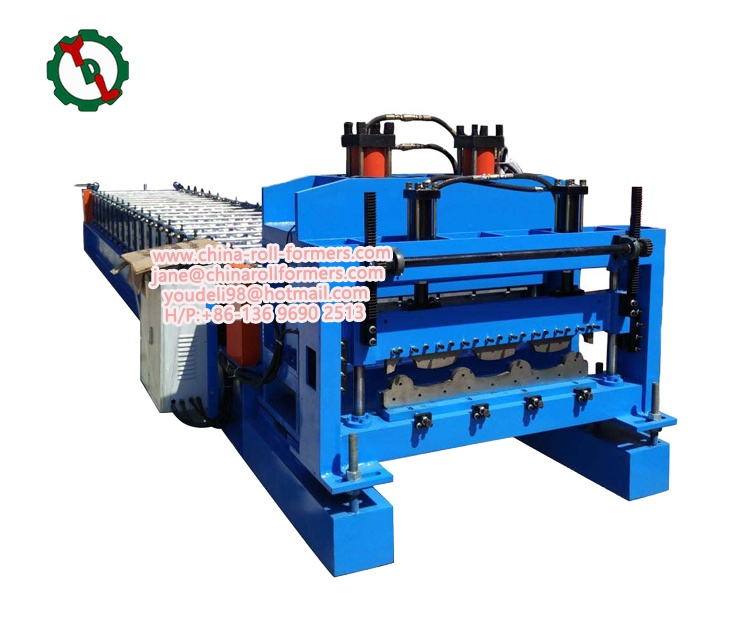

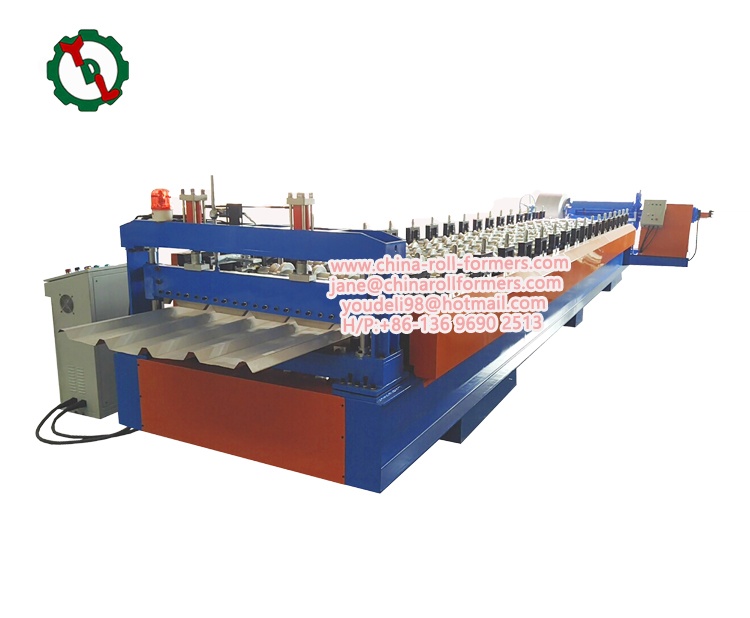

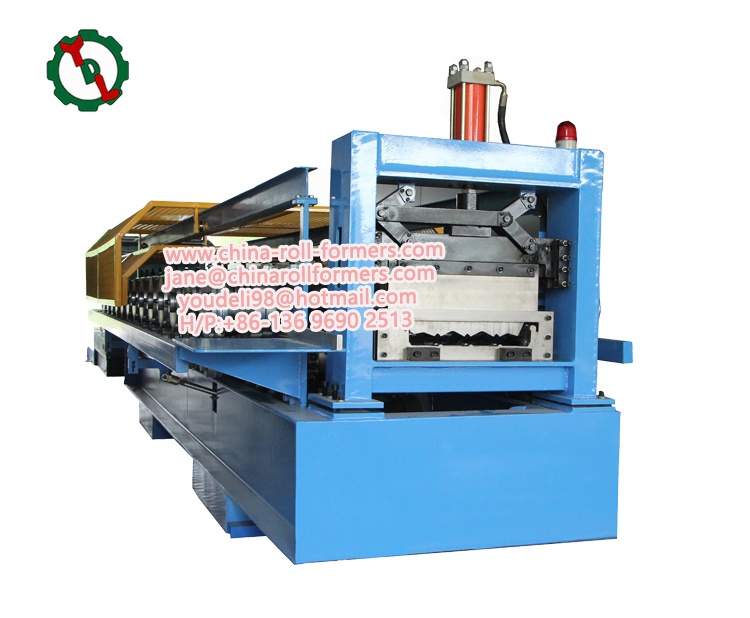

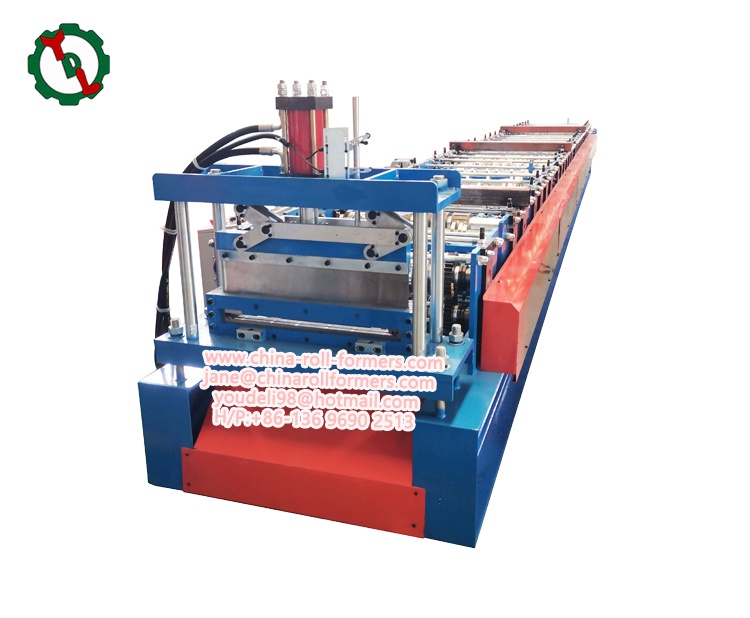

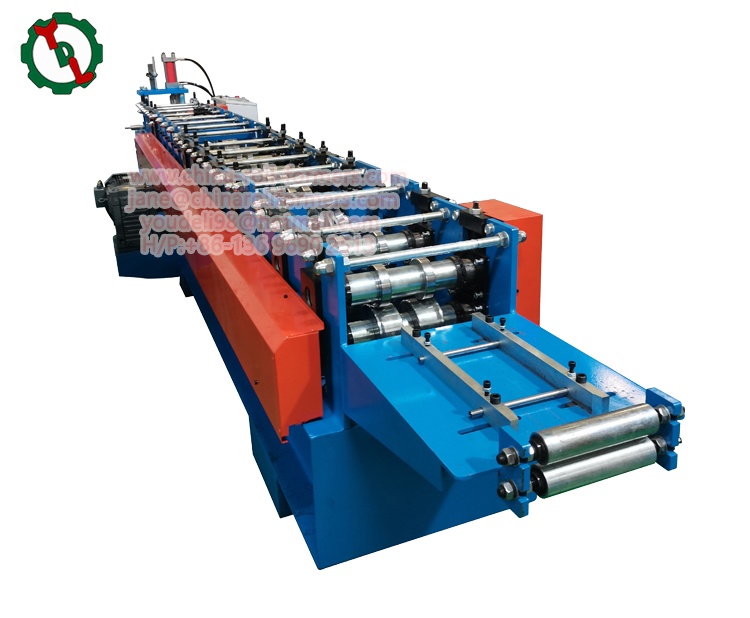

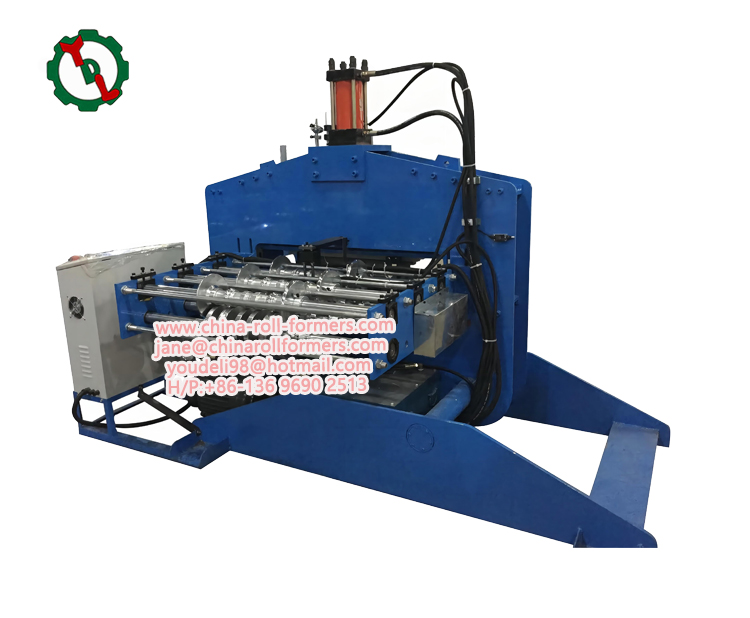

One of the most important parts of any building is the roof, which shields the structure from weather conditions like rain, snow, wind, and hail. The roof must be built with high-quality components and methods to guarantee long durability and effective operation. The locking lapping method, which is popular in the construction sector, is one such method. A locking lapping roofing roll making machine is utilized to make this method easier. The interlocking panels made by the locking lapping roofing roll forming machine are perfect for roofing. Metal coils are fed through a set of rollers, which gradually shape them into the desired profile, to make the device work.

This machine creates panels with a distinctive shape that enables them to closely interlock with one another, ensuring a leak-proof and solid junction. The panels' distinctive form also makes installation simple, requiring less time and effort. The locking lapping roofing roll forming machine is offered in a variety of styles and dimensions to meet the wide range of demands of the construction sector. Snap-on standing seam, trapezoidal, and corrugated roofing panels are a few of the popular patterns. These plans can be used for both commercial and residential buildings, depending on the situation. Contractors may tailor the panels to match the specifications of certain projects thanks to the machine's ability to make them in a variety of lengths and widths.