Purchase Qty: 1 Set

Port: Xiamen China

Payment Terms: L/C, T/T

Fob: Inquiry Price

Certification: CE, ISO

Condition: New

Customized: Customized

Automatic Grade: Automatic

Transmission: Motor and Chain For Driving

Means of transport: By sea as full container

Packing: Standard for export

Delivery time: 60 days

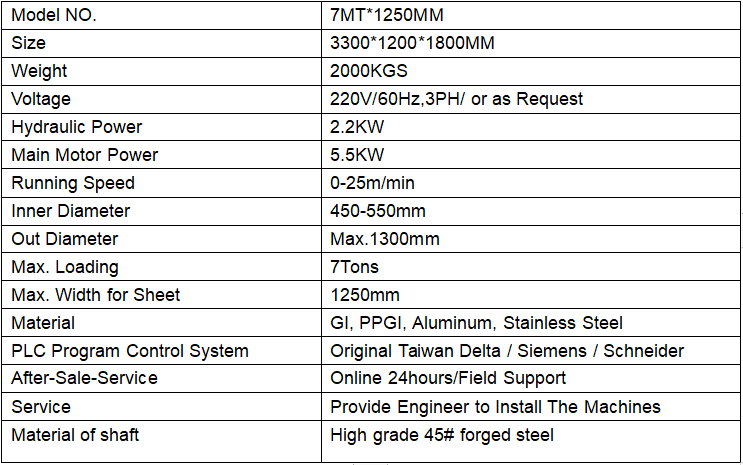

Products Parameters

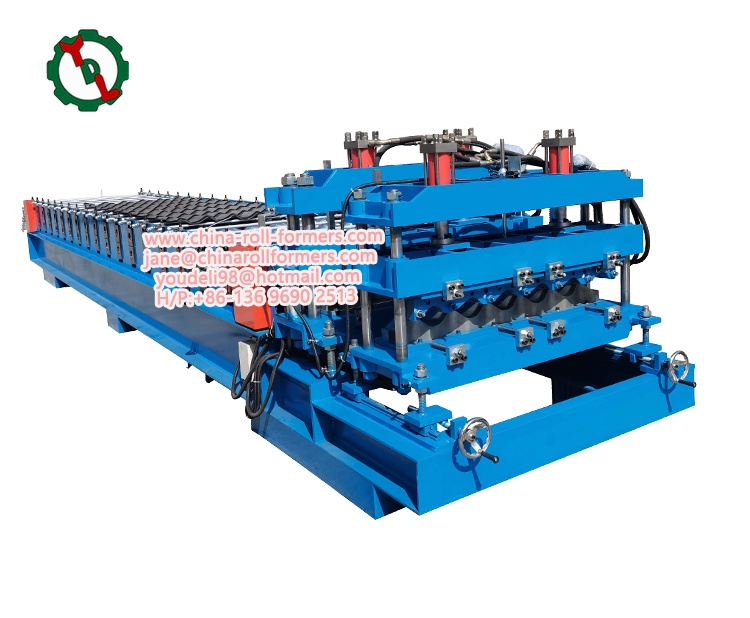

Products Description

Hydraulic Uncoiler is an important industrial equipment, mainly used to support and loading various metal coils, such as Steel Coil, Aluminum Coil, Copper Coil etc.. Its main components include hydraulic system, frame structure, discharge mechanism and auxiliary components.

The hydraulic system is the core part of the hydraulic uncoiler, which is composed of hydraulic pump, oil cylinder, pipeline and various control valves. The hydraulic pump is driven by an electric motor to produce high pressure oil, which is transported to the cylinder through the pipeline. The cylinder is extended or retracted through the control valve, so as to realize the lifting control of the frame structure.

The frame structure is the main part of the hydraulic loading rack, usually made of steel material. It is mainly composed of columns, beams and diagonal braces to form a stable structure that can withstand the weight and pressure of various materials.

The loading mechanism is the key part of the hydraulic uncoiler, which can be composed of main shaft, coiler, inclined plate, etc. According to different material characteristics, the appropriate loading mechanism can be selected to make the material fall evenly and gently under the control of the hydraulic system.

Auxiliary components include electrical control system, safety protection device, etc. The electric control system can realize the automatic control of the hydraulic system and improve the automation degree of the equipment. Safety protection devices can ensure the safety of operators and prevent accidents.

The use of the hydraulic uncoiler varies according to the material characteristics and production process. In general, the operator can adjust the control valve of the hydraulic system according to the characteristics of the material and the requirements of the production process, so that the frame structure is lifted to the appropriate position, and then the material is evenly and gently dropped through the loading mechanism. At the same time, the operator also needs to check and maintain the hydraulic uncoiler regularly to ensure the normal operation and safety of the equipment.

When using hydraulic uncoiler, the following matters should be noted:

1、The load of the hydraulic support should be operated according to the specified load range, not overload or overload.

2、During the operation, the stability and oil pressure of the support should be observed at any time. Once abnormal conditions are found, the operation should be stopped in time and checked.

3、The operation of the hydraulic support should wear safety protection equipment in line with the standard, such as gloves, safety shoes, etc.

4、The operation time of the hydraulic support should be controlled within the specified range, too long operation time will make the hydraulic oil temperature rise, thus affecting the service life and safety of the equipment.

5、Preparations should be made before moving the frame, including checking whether the pipeline, valve group and cable are in good condition, whether the spare parts of the materials are complete, observing the top plate, and handling the umbrella eaves, bottom coal and soft bottom plate. At the same time, the spacing of the support should be adjusted evenly, and the coal wall, the support and the conveyor should be kept in a straight line. The runway should be clean, the floating coal should not be much, and the coal waste that falls off the sheet or roof should be cleaned up in time; The floating coal in the bracket or the gangue falling between the brackets should be removed.

6、In the transfer operation to be fast, enough, positive. The shearer should move the frame as soon as possible after cutting coal, so as to complete a quick pull with less drop. The distance of pushing and sliding should be sufficient, and the distance of pulling (moving) frame should ensure that the specified progress is achieved. When pulling the frame, it is necessary to make the support not crooked, not inclined, not sliding, and the adjusting jack should cooperate with the action.

Following the above precautions can ensure the safe and stable operation of the hydraulic discharge rack and improve the service life and production efficiency of the equipment.

Our Certificate

Cargo Loading

Why Choose Us?

Sample Chamber