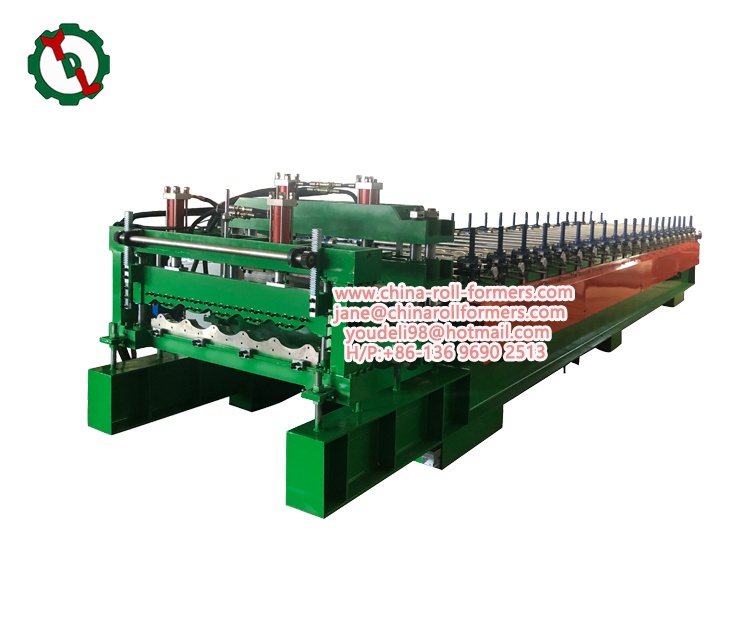

The Purlin Forming Machine and the C Purlin Roll Forming Machine are both types of roll forming machines used in the production of purlins, which are horizontal beams commonly used in the construction of roofs and walls. The main connection between the two lies in their function to shape steel or metal strips into purlins, although they may differ in their design and specific output.

The Purlin Forming Machine is a broader term that encompasses various types of roll forming machines used to create purlins in different shapes and sizes, including C, Z, and U-shaped purlins. On the other hand, the C Purlin Roll Forming Machine is a specific type of purlin forming machine designed to produce C-shaped purlins. These machines work by feeding metal coils through a series of rollers that gradually shape the metal into the desired profile, with the C purlin being particularly popular for its structural strength and versatility in construction.

Both machines are essential for efficiently manufacturing purlins in large volumes, ensuring precise and consistent profiles that are crucial for the structural integrity of buildings. The C Purlin Roll Forming Machine can be seen as a specialized version of the more general Purlin Forming Machine, focusing on producing C-shaped purlins for various applications in the building and construction industry.

The C Purlin Machine and C Purlin Roll Forming Machine are essential equipment for producing high-quality C-shaped purlins, widely used in construction and structural applications, offering precision, efficiency, and durability in metal framing production.

Applications of the C Purlin Machine

The C Purlin Machine is widely used in various industries for producing C-shaped purlins, which are essential components in the construction of steel structures. Here are some key applications of the C Purlin Machine:

- Roofing Systems: C purlins are commonly used as support beams for roof structures, providing stability and strength to roofing panels in commercial and residential buildings.

- Industrial Buildings: The machine produces C purlins that are used in the construction of warehouses, factories, and storage facilities, where strong, reliable support is needed for the roof and walls.

- Steel Frame Buildings: C purlins are vital in the formation of steel-framed structures, acting as the horizontal support beams that carry loads from the roof to the columns.

- Agricultural Buildings: In agricultural structures such as barns, greenhouses, and silos, C purlins help create a durable frame that supports various components, including roofing and cladding.

- Bridge Construction: C-shaped purlins provide structural integrity and support in bridge construction projects, helping to distribute the load efficiently across the structure.

- Pre-engineered Buildings (PEBs): The C purlin machine plays a critical role in manufacturing components for PEBs, which are used for industrial, commercial, and even residential construction projects.

- Renewable Energy Applications: C purlins are also used in the construction of structures for solar panel installations and wind turbine towers, where they are needed to provide support and stability to the energy systems.

- Temporary Structures: C purlins are used in the construction of temporary or modular buildings, which require easily assembled and reliable framing solutions for short-term use.

In summary, the C Purlin Machine is crucial in creating versatile, high-strength components used across multiple sectors, ensuring structural integrity in a wide range of building and industrial applications.

Parameter

Model NO C75-300

Size 11000*1970*2100mm

Weight 11000KGS

Voltage 220V/60HZ,3PH/ or as Request

Motor Power 30KW

Hydraulic Power 0.37KW*2+0.75KW+0.18KW*2

Thickness 0.7-2.0mm

Forming Steps 18steps

Working Speed 0-25m/min

Lip of C Purlin 8-15mm

Flange of C Purlin 35-70mm

Web of C Purlin 70-300mm

Tolerance for cutting, forming ±2.0mm

Material GI PPGI Aluminum

Our advantage

servo motor

- High output power relation

- Small size, high efficiency, faster speed and more stable torque Closed loop

- Adjust low-profile operation, high reliability, high inertia ratio

- Accelerate quickly and high-speed function

- Torque regulation

- smooth motion

- High precision

- Ideal for changing load conditions

big roller

Larger diameter drums also indicate higher line speeds, and larger drums are stiffer and more stable.

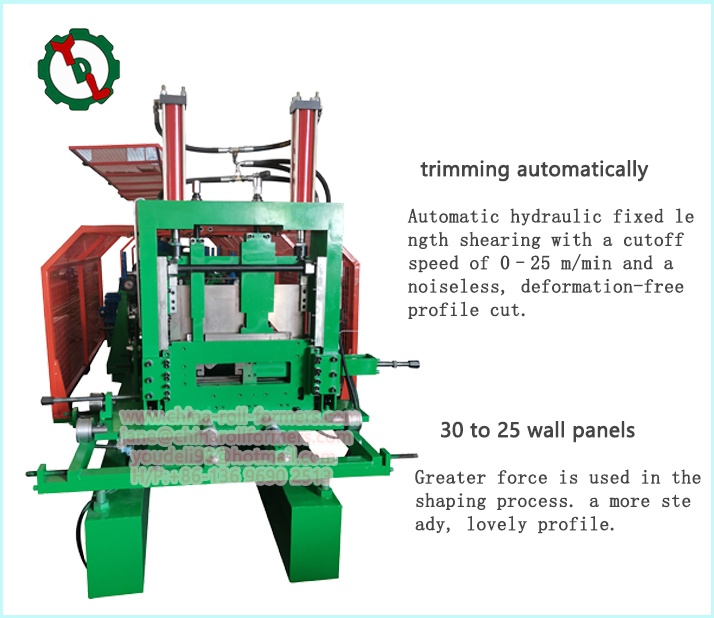

hydraulic press system

- The first stop: Punching the center hole of the bottom

- The second station: drilling holes and side holes

- The shape will not be imperfect after punching, and it will not be distorted by the roller.

5T Manual Decolier

- Volume: 5 tons

- Inner coil diameter: 450–550mm

- Feeding width: 500mm maximum

- Steel plates and shaped bars are used in the structure’s welding.

- Automatic coil expansion and contraction powered by hydraulics.

Device for Feeding and Leveling

Here is an electronic button that allows the feeding width to be adjusted automatically.

Rollers for leveling: 3 up and 4 down

Roller composition: Cr15

75mm roller diameter

Automatic feed width adjustment by the

Make sure that the steel sheet input is straight and orderly so that the roll forming process may be accurate.

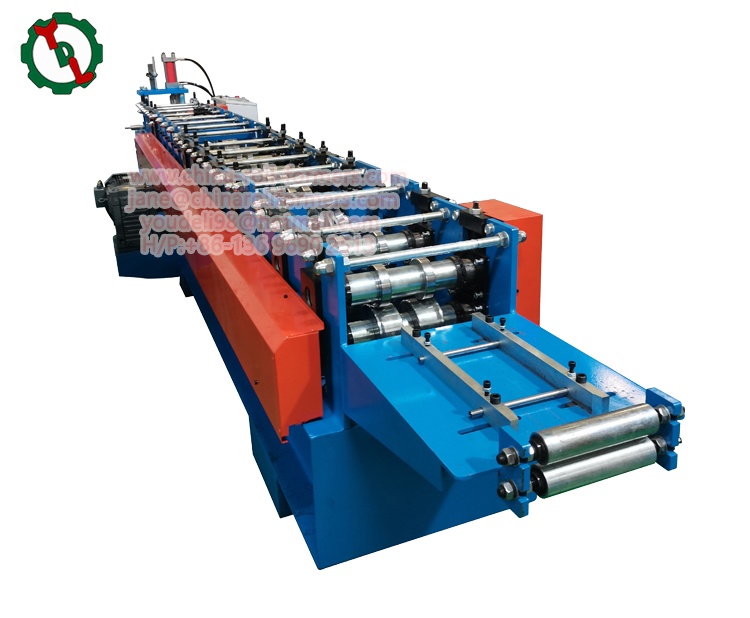

Device For Roll Forming And Transmission

Rollers are made of Cr12. turning after CNC processing and heat treatment to HRC: 58–60 21 rows of 12 unit roller stations for C and Z changeover are available. Shaft substance:Material for shaft: 40 Cr CNC turning, finishing, and electroplating HRC 28-32 1.5 inch drive by heavy duty chains

Device for Hydraulic Cutting

Blade construction: Cr12mov quench treatment

Measuring length automatically with an encoderThe length has a tolerance of 3000mm+- 2.0mm.

The cutter may be manually adjusted to cut c/z purlin in a variety of sizes. This cutter is simple to use and does not require a new blade.

Computer Control System

Our machines adopt the Taiwan PLC brand, including Delta PLC, inverter and touch screen, as well as Omron encoder and Schneider Electric parts. These high-quality electronic components ensure the reliability and stability of the machine. Our control system supports multiple operating languages such as English and Chinese to meet the needs of our customers. The operation is very simple, you can easily set up the order in the system, and change the length and quantity of the product. In addition, our machines are equipped with aviation plugs, which makes the machine installation easier and more convenient.

- We use modern automatic control information management production software to ensure the high efficiency and precision of the production process.

- The rollers on each piece of equipment are made of high-strength 45# hardened steel to increase its toughness and durability. In addition, we also electroplate the surface of the roller to improve the main performance of the equipment and ensure its long-term stable operation.

- The movable workbench of the cutting device adopts hydraulic control, which has excellent flexibility and reliability and can meet various production needs.

A brand-new, fully automatic interchanged steel frame purlin roll forming device has just been created, and it’s poised to transform the building sector. With astounding speed and accuracy, this machine is able to produce high-quality purlins in a range of sizes and shapes, including C, Z, and U profiles.

This machine’s automatic interchanging mechanism, which enables quick and simple changeover between various profile forms, is one of its primary advantages. By doing this, purlins are produced consistently and precisely while also saving time and effort.

This machine’s digital control system, which lets users to set and modify several parameters like cutting length, hole distance, and molding speed, is another benefit. In order to protect its users, the device also contains a safety mechanism that detects abnormal situations and shuts down the operation immediately. This device can be used in a broad variety of settings, including industrial facilities, infrastructural projects, and residential and commercial buildings. This machine is anticipated to lower building costs and raise the caliber of finished goods by offering a more effective and dependable purlin production solution.