Product Introduction

Smooth Curving Machine is suitable for processing many kinds of materials, common including iron, aluminum, copper, stainless steel, titanium alloy and so on. Each of these materials has unique mechanical properties, such as hardness, toughness, tensile strength, etc., which may affect the results of bending processing. Smooth bending machines bend materials into different shapes by adjusting angles and radians to meet a variety of different manufacturing needs.

Working Principle of Smooth Curving Machine:

The working principle of the smooth curving machine is based on the basic principle of material curving. When the material passes through it, the machine exerts an external force on the material, causing it to bend and deform in the axial direction. It adopts a precision transmission system and control system to ensure machining accuracy and stability. Specifically, it is usually composed of a curving wheel, a fixture, a transmission system, and a control system. During processing, the material is fixed on the conveyor belt through the fixture, and the curving wheel exerts curving force on the material to make it bend and deform in the axial direction. At the same time, it adopts a high-precision servo control system to control the movement track and speed of the curving wheel to ensure machining accuracy and quality. Additionally, it is also equipped with a variety of different fixtures and curving wheels, which can be selected according to the characteristics of different materials to obtain the best processing results. In short, the working principle of it is to apply curving force to the material through the precision transmission system and control system, so that it can bend and deform, achieving the purpose of processing.

The Smooth Curving Machine represents the pinnacle of curving technology, offering a blend of precision, efficiency, and versatility. Its advanced features and robust design make it an ideal choice for businesses looking to enhance their metal bending capabilities while ensuring quality and safety. Whether you’re in automotive, aerospace, construction, or any other industry requiring precise metal curving, this machine is engineered to meet your needs and exceed your expectations.

Smooth Curving Machine Structure

The driving rolls on a CNC standing seam crimping machine are the side rolls, the lower roll, and the side roll can move up and down. The upper roll and lower roll are driven by a hydraulic motor, and the side roll is driven independently of the other two rolls. The lifting motion is accomplished by pushing the oil cylinders at both ends. The overturning oil cylinder turns and resets the front bearing body of the top roller. The bearing body and oil cylinder of each roller are mounted in the frame at the left and right ends.

The primary body of the CNC standing seam bending machine is made up of the left and right frames, which are assembled on the general basis using a welding structure and CNC machine tools. All machine actions are carried out on the console after the workpiece is rolled and the turning cylinder is turned. The workpiece is then pushed out of the machine by the unloading device.

The steel plate can be clamped by the upper and lower rollers of the CNC standing seam rolling machine to stop it from slipping when rolling.

When feeding, the side rollers can be used for positioning and to align the steel plates. Bending conical, oval, and uniquely shaped pieces is simple.

The steel plate was bent and rounded on the CNC standing seam curling machine.

Smooth curving machine, as an advanced manufacturing equipment, is more and more widely used in various industries. With its unique processing methods and efficient production capacity, it has gradually become a leader in the manufacturing industry. This paper will introduce the characteristics, application and development trend of smooth surface bending machine in detail.

Characteristics of smooth curving machine

Smooth curving machine is a kind of high-precision processing equipment, mainly used for bending, straightening and forming various materials. Its biggest feature is that it can achieve high precision processing, and the surface after processing is smooth and no scratches. In addition, the smoothcurving machine also has the advantages of high automation, high production efficiency and easy operation.

We design and build the entire control system for our machines. We hired a qualified engineer to create the control system. curved color

steel roofing sheets from a prior machine angle When a customer has a control issue, we can quickly address it thanks to the hydraulic arch camber curving roll forming machine. ECO-FRIENDLY SPRAYING TECHNIQUES Curving former machine angle color steel roofing sheets hydraulic arch camber curving roll forming machine electrostatic spraying equipment ensures that the machine will be delivered on schedule and complies with all environmental protection laws set forth by the Chinese government.

Preduct Structure Features

1. Pipe and Tube Bending

They are used to bend metal pipes and tubes into various shapes, such as U-bends, elbows, and coils. These shapes are essential in the construction of pipelines, exhaust systems, and HVAC systems.

2. Sheet Metal Bending

They are used to bend sheet metal into various shapes, such as boxes, frames, and channels. These shapes are essential in the construction of cabinets, enclosures, and structural components.

3. Automotive Body Fabrication

They are used to bend metal sheets into various shapes, such as fenders, hoods, and doors. These shapes are essential in the fabrication of automotive bodies and frames.

Advantages of our equipment

For bending metal panels of various widths and thicknesses, our standing seam benders are the best choice. Its sturdy and solid frame guarantees stability while bending.

Additionally, our equipment has user-friendly interfaces that make it simple for operators of all experience levels to operate.

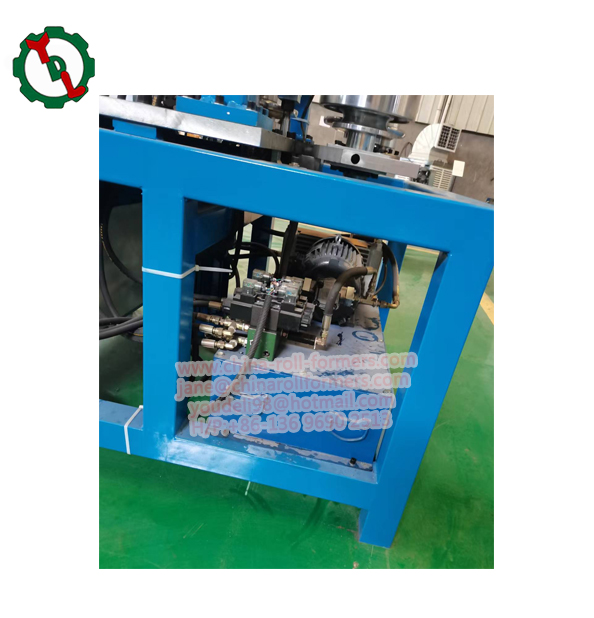

The machine’s sophisticated hydraulic mechanism allows the rollers to move in flawless unison. The panels are continually bent properly and consistently thanks to this function and its high-torque motor.

Additionally, our machines feature variable speed controllers that let users alter the bending speed to suit their requirements.When bending panels of different widths and thicknesses, this capability is helpful.

Our standing seam benders are made to work with a wide range of metal roofing applications, including residential, commercial, and industrial projects. Additionally, it may be tailored to fit certain needs, guaranteeing that every product is manufactured specifically to satisfy the demands of various projects’ roofing designs.

Your demand for metal bending has an engineered solution with Marklin’s standing seam benders. It is the best option for producers and contractors of metal roofing due to its cutting-edge technology, usability, and adjustable features.

Curving machines are a crucial piece of equipment for the manufacturing and construction sectors. Materials such as pipes, tubes, and wires are formed into curved shapes using these devices. With uses ranging from aesthetic features to structural components, they are frequently employed in the automobile, aerospace, and construction industries. The roll bender is the most prevalent kind of bending machine. Metal sheets and profiles can be bent and shaped into curves using roll benders, which have a set of rollers. They are frequently used to make curved channels, pipes, and angles. Some roll benders are versatile equipment for shaping many sorts of materials because they may also be used for rolling plates and cylinders.

The mandrel bender is another kind of machine for bending. In order to maintain a constant curve during the whole process, mandrel benders support the material being curved with a mandrel. This kind of tool is frequently used, especially in the automotive industry, to bend pipes and tubes into precise curves. Machines specifically designed for bending tubes and pipes are known as tube and pipe bending machines. Depending on their intended application, these devices come in a variety of sizes and designs. Large diameter pipes can be bent using some tube and pipe bending equipment, whereas tiny and medium-sized tubes can be bent precisely using other equipment.

Construction companies frequently employ bending machines to make curved beams and columns. Typically huge and powerful, these machines can work with thick metals and big profiles. They can be employed to produce architectural elements or curved-shaped structural elements. It’s crucial to take the type of material, the necessary curvature, and the intended application into account when choosing a curving machine. For particular materials and purposes, some machines are better suited than others.

Additionally, many machines may create a variety of curves, from straightforward arcs to more intricate designs. Curving machines are crucial instruments for the construction and manufacturing sectors. In addition to pipes and tubes, they can also be utilized to make decorative accents and structural features. Selecting the ideal equipment for your unique needs requires a thorough understanding of the various types of bending machines and their applications. Whether you run a small business or are a major manufacturing, adding a curving machine to your workflow can help you accomplish your goals more quickly and precisely.

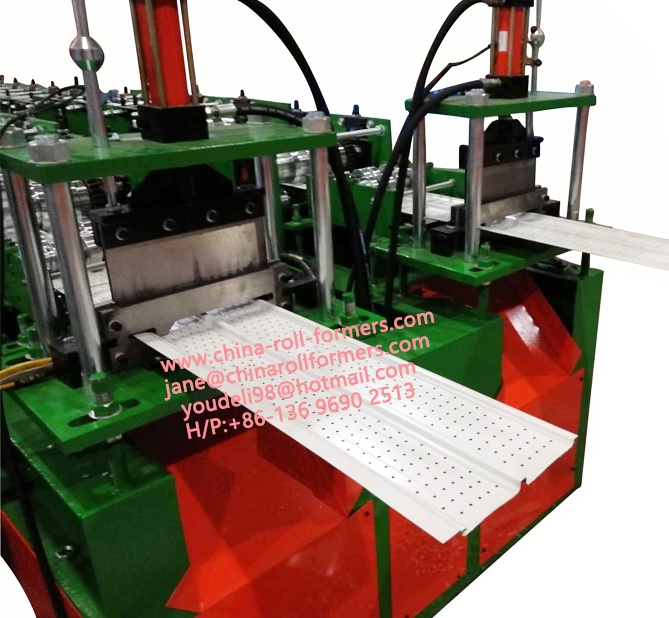

PRODUCT DISPLAY

WHY CHOOSE US

CERTIFICATE

AXES AND ROLLERS

RELATED MACHINERY

CARGO LOADING

| Model NO. | YX65-300-600 |

| Size | 1500*850*2000mm |

| Weight | 1500KGS |

| Voltage | 380V/50HZ,3PH/ or as Request |

| Electric Motor Power | 4KW |

| Hydraulic Power | 3KW |

| Motor for changing models Power | 0.37KW |

| Curved Thickness for Aluminum | 0.8-1.2mm |

| Curved Thickness for Steel | 0.6-1. 0mm |

| Width of roofing to curve | 300mm to 600mm |

| Min.Width of Tapered Roofing to Curved | 250mm |

| Max.Width of Tapered Roofing to Curved | 500mm |

| Working Speed | 0-12m/min |

| Forming Steps | 3 steps |

| Min. Curved Radius for Aluminum Roofing | Convex Curved 2M,Concave Curved 8M |

| Min.Curved Radius for Steel Roofing | Convex Curved 5M,Concave Curved 10M |

| Main usage | Rolling curving the roofing with Crimping Convex Shape |