Purlins are an essential component in metal building construction, providing support for roofs, walls, and other structural features. The two most prevalent varieties of purlins are C-shaped and Z-shaped, and while they look similar, there are some significant distinctions in purpose and shape.

Purlin of the C type

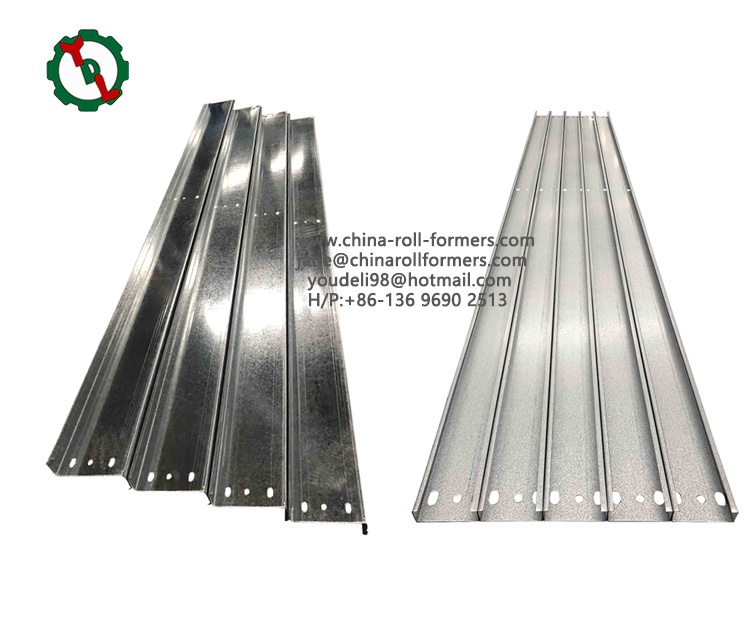

The name comes from the shape’s resemblance to the letter “C.” They have a horizontal (also known as a flange) and a vertical (or lip) portion. C-shaped purlins are often used on roofs and walls in industrial and commercial buildings because they are highly adaptable and may be installed in a variety of configurations, including gable and lean-to roofs.

Purlin of the Z type

It is shaped like the letter “Z” with two horizontal pieces (flanges) and one vertical segment (or lip). They may also be used for roofs and walls, although they are most commonly utilized in structural framing applications like long-span mezzanine floors, roofs, and canopies. Because of its design, Z-purlins are more efficient at bearing loads, making them suited for projects with long spans.

The operation and procedure of a C-type purlin machine and a Z-type purlin machine are identical in terms of production. To make high-quality purlins, they both employ steel coils and cold roll forming procedures. However, these machines are designed differently; the C-type purlin machine produces C-type purlins, whilst the Z-type purlin machine produces Z-type purlins. Each of them has unique characteristics and advantages for manufacturing different purlin shapes.

It is important to choose the shape of the purlins that suits the needs of the project. C-shaped purlins are suitable for smaller roof or wall applications, while Z-shaped purlins are suitable for large span and structural frame applications. Therefore, selecting a machine that suits your needs is a critical step in ensuring the success of your project.

Parameter

Purchase Qty. 1 Set

Port: Xiamen China

Payment Terms: L/C, T/T

Certification: CE, ISO

Condition: New

Customized: Customized

Automatic Grade: Automatic

Transmission: Motor and Chain For Driving

MAIN INFO

Model NO. C80-300,Z140-300

Automation Full-Automatic

Language English

Guaranty 12 Months

Transport Package Naked Packing

Color Blue or According to Customers′request

Cutter Type Hydraulic Cutting

Control System Controlled by PLC

VIDEO

MAIN TECHNICAL PARAMETER

Cold formed thin-walled steel, profiled steel plates, and other materials are all part of the C-type steel machine’s product line. They can increase the efficiency of the steel and enhance its ability to cut thanks to their reasonable cross- sectional shape. It is simpler to connect with high-strength bolts and other components because the wing pattern has been expanded and the inner and outer surfaces are often parallel, unlike regular H-shaped steel. It’s easy to develop and select because of its suitable size composition within the series and full models. C-shaped steel machine that continuously cuts. After going through several stages of evolution, from non-interchangeable to interchangeable, a wide variety of ways were used to the half set of interchangeable models.

The C-shaped steel machine for endless cutting is primarily made up of a number of pieces, such as a passive feeding frame, a feeding frame base, a feeding intake platform, a leveling device, a forming host, a punching device, a forming cutting device, a hydraulic station, a computer control cabinet, etc.

C-shaped steel production process flow placing the materials – cutting – rolling -shaping – punching – completed product Specifications for C-shaped steel:

Dimensions of the apparatus Size11800*2000*2100mm

about 6 tons of equipment weight 1.5 to 3 mm is the pressing thickness There are 15 rows total, with 3 rows for leveling and 12 rows for shaping.11 kW of motor power,80 mm (solid spindle) is the size of the forming shaft,Shaft (galvanized Le) and wheel (steel bearing),

350H steel frame,Medium-thickness plates are 18mm.

MASTER DIAGRAM

PRODUCT STRUCTURE FEATURES

1.High-quality purlins: The CZ Purlin Interchanged Roll Forming Machine is designed to produce high-quality purlins that are strong and durable. These purlins are designed to stand the harsh conditions of the construction site.

2. Efficient production: The CZ Purlin Interchanged Roll Forming Machine is designed to produce purlins efficiently. This machine can produce purlins at a high rate, which means you can produce more purlins in less time.

3. Versatility: The CZ Purlin Interchanged Roll Forming Machine is a versatile machine that can produce different types of purlins, including C purlins, Z purlins, and U purlins.

4. Cost-effective: The CZ Purlin Interchanged Roll Forming Machine is a cost-effective solution for producing purlins. This machine can produce purlins at a lower cost than conventional methods of producing purlins.

5.Easy to operate: The CZ Purlin Interchanged Roll Forming Machine is easy to operate. This machine is designed to be user-friendly, which means that anybody can operate it with minimal training.

RELATED MACHINERY

OUR CUSTOMERS EXHIBITION

OUR SERVICES

1.Installationandtraining:

- If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers / technician face to face.

- Without visiting,we will send you user manual and video to teach you to install and operate.

- If the buyer needs our technician to go to your local factory, please arrange board and lodging and

other necessary things.

2.after service

- One year guarantee for whole machine

- 24 hours technical support by email or telephone call.

- If there is any problem found of the machine,we will repair it for free in one year.

CARGO LOADING

SHIP EQUIPMENT