Our electric seaming machine is a versatile and reliable solution for sealing a variety of packaging materials, including bags, pouches, containers, and cans. Designed for efficiency and precision, this machine ensures airtight and secure seals, preserving the freshness and integrity of the contents.

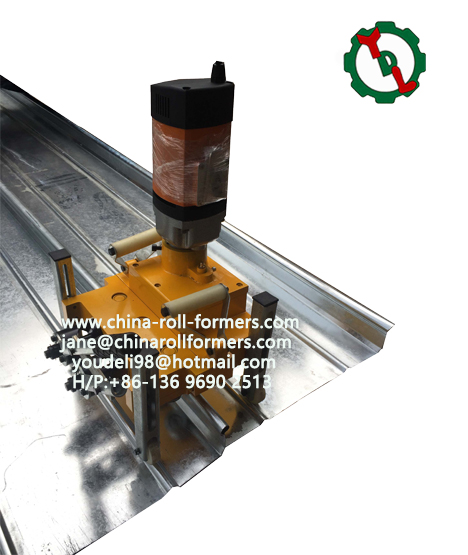

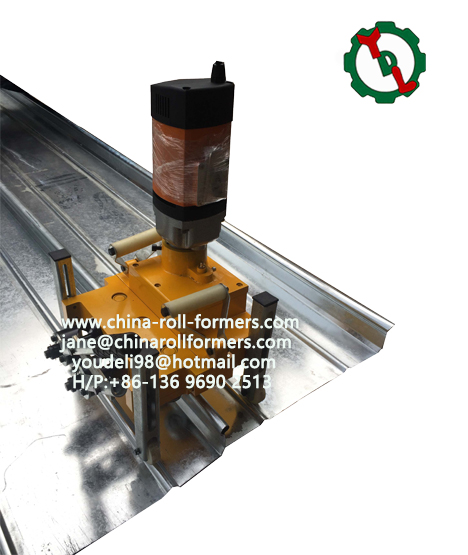

Advantages of Roof System Electric Seam Sealer

- Efficiency: The electric seaming machine we produce can complete the seaming task quickly and efficiently. They are able to handle a large amount of work in a short period of time, increasing productivity.

- Accuracy: The electric seam sealer has a high degree of accuracy and control. Operators can precisely control the depth, width and tightness of the seam, ensuring that every seam is within specification.

- Reduced Labor Requirements: The use of these machines reduces the need for manual seaming. This not only reduces labor costs but also reduces the risk of human error.

- Sturdy and durable: At Youdeli, our machines are all made of high-quality materials with good durability. They can work under harsh environmental conditions and maintain performance for a long time.

- Versatility: The Roof Systems Electric Seam Sealer is suitable for a variety of materials, including metal, plastic, rubber, and more. This makes them a versatile tool for a wide variety of projects and applications.

- Improved airtightness: Due to its high precision, our machines are able to ensure excellent airtightness of the seams. This helps prevent the seepage of water, air or other substances and increases the durability of the building.

- Safety: The electric seaming machine has safety functions such as two-hand start, automatic stop and safety warning system to reduce the risk of operation.

- Less waste: The machine is characterized by high precision, so the risk of wasting material is reduced. They enable precise application of joint sealant without additional repair work.

Roof system electric seam sealers offer significant advantages to construction and engineering projects by increasing efficiency, precision and safety, as well as reducing labor requirements and waste.

Electric Seaming Machine Application

- Packaging Industry: They are used to seal various types of packaging materials, such as bags, pouches, and containers. They ensure that the contents remain fresh and protected from external elements.

- Food Industry: In the food industry, electric seaming machines are used to seal cans for products like fruits, vegetables, soups, and beverages. These machines help maintain the quality and freshness of the food products.

- Beverage Industry: They are crucial in the beverage industry for sealing cans containing carbonated drinks, juices, and other beverages. They help maintain the carbonation and prevent leaks.

- Pharmaceutical Industry: In the pharmaceutical industry, electric seaming machines are used to seal containers for medications, ensuring their safety and integrity. These machines are essential for maintaining the quality of pharmaceutical products.

- Chemical Industry: They are used in the chemical industry to seal containers for various chemicals and liquids. They help prevent leaks and spills, ensuring safety in handling hazardous materials.

- Cosmetics Industry: Electric seaming machines are used to seal containers for cosmetic products like creams, lotions, and powders. They help maintain the freshness and quality of cosmetic items.

An electric seam sealer is an installed device applied to standing seam roofs to create interlocking seams that join adjacent roof panels, ensuring a weathertight seal. At youdeli, electric seamers offer multiple advantages including seaming speed, precision and consistency. They are designed to deliver reliable and repeatable results, reducing the margin of error during manual seam creation. Additionally, the power supply ensures consistent force and pressure, resulting in high-quality seams. The versatility, efficiency, and ability to deliver consistent results made with electric seamers make them invaluable tools in metalworking, roofing, and a variety of manufacturing processes.

Master Diagram

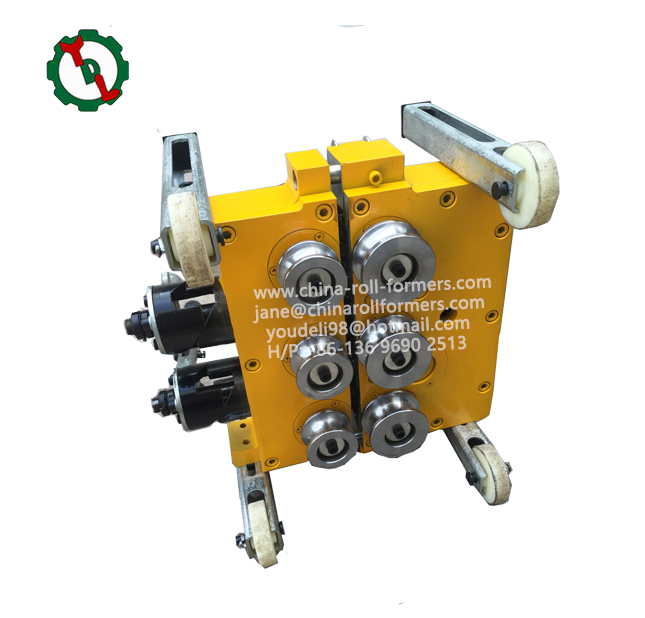

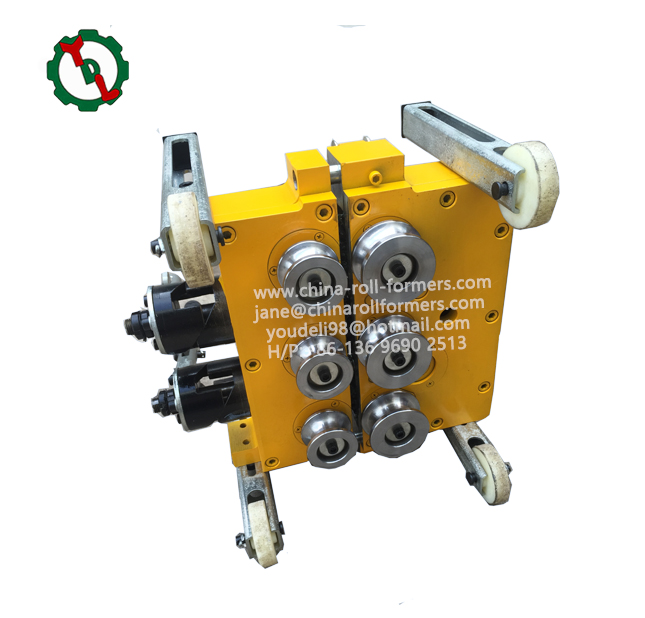

Three components make up the structure: the feeding part, the transmission part, and the forming part.

1, the forming part, mostly refers to the central roll-shaped component of the machine. when there is excessive feed or extrusion molding occurring between the two rollers.

2. The feeding process, which is primarily manual and involves feeding into the space between the rolls.

3. A triangle belt motor, a reducer, an open gear, and a roll make up the transmission system. The electromagnetic speed-regulating motor supplies the main engine with dynamic force, which is then transferred to the drive shaft via the belt pulley, the cylindrical gear reducer, and the rod pin coupling.

Material

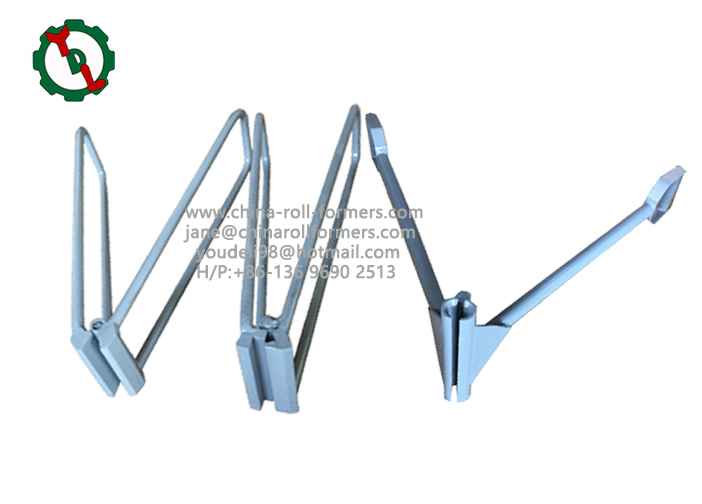

1, aluminum alloy support, aluminum alloy bracket, with heat insulation pad.

Height: 65/75/80/85/90/100/106/115/125/135/155/161/165/169/181/196/211

Tilt head: 85/115/161

2, steel structure roof plate series bracket, Angle, hidden buckle, vertical locking, model ***, large special specifications can be made by sample mold. Material Hot dip galvanized/stainless steel 201-304.

Model: 406/420 bracket 430 brackets 470 brackets 475 brackets 478 brackets 600 brackets 666 brackets 750 brackets 760 brackets 788 brackets 820 brackets 840 brackets 950 brackets.

3, metal roof windproof reinforcement, secondary reinforcement, covering the stadium/exhibition center/pillar-free awning/train platform/large factory/terminal metal roof/color steel tile/aluminum magnesium manganese plate reinforcement.

Type 400/430: Flat fixture, L-shaped fixture, point fixture, double fixture, stainless steel L-shaped, galvanized double fixture.

760/820: L fixture new non-slip size opening.

Model 470/475:470 double fixture 470 anti-slip fixture.

4, metal roof electric automatic bite pliers, locking machine.

Model:760/820, 470/475, 400/430 Manual bite pliers/Manual clamp/Manual tile clamp.

Model:760/820, 470/475, 400/430 electric edging machine/Electric biting machine.

5, vertical locking metal roof (YX65-300/400/420/430/500/600)

The quality of metal roofing plates is generally: aluminum magnesium manganese alloy roofing plate, aluminum zinc metal roofing plate, color steel metal roofing plate and so on.

Angle type metal roof (YX51-YX76-380-760/820)

Angle Chi III Angle Chi II medium crest (tile rib) Side crest (tile rib)

360-degree locking metal roof (HV-U470/475/468/478/490)

Company Profile

Main Technical Parameter

| Model NO. | YX25/38-220-530 |

| Seamer Size | 350*300*450mm |

| Package Size | 420*350*500 |

| Net Weight | 20KGS |

| Gross Weight | 36KGS |

| Steps | 3 Steps |

| Voltage | 220V,Single-phase |

| Power | 2.4KW |

| Working Speed | 16-20m/min |

| Material of Standing Seam Roofing | Aluminum,GI,PPGI |

| Thickness of standing seam roofing | 0.8mm |

| Usage | Automatically Seaming Seam Roofing |

| Painted Color | Yellow or Customization |

CE Certificate

AXES AND ROLLERS

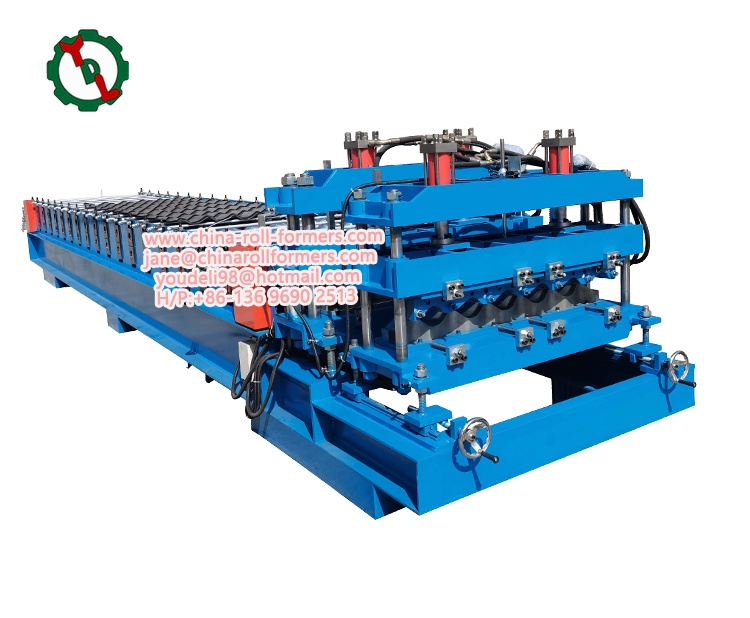

RELATED MACHINERY

CARGO LOADING