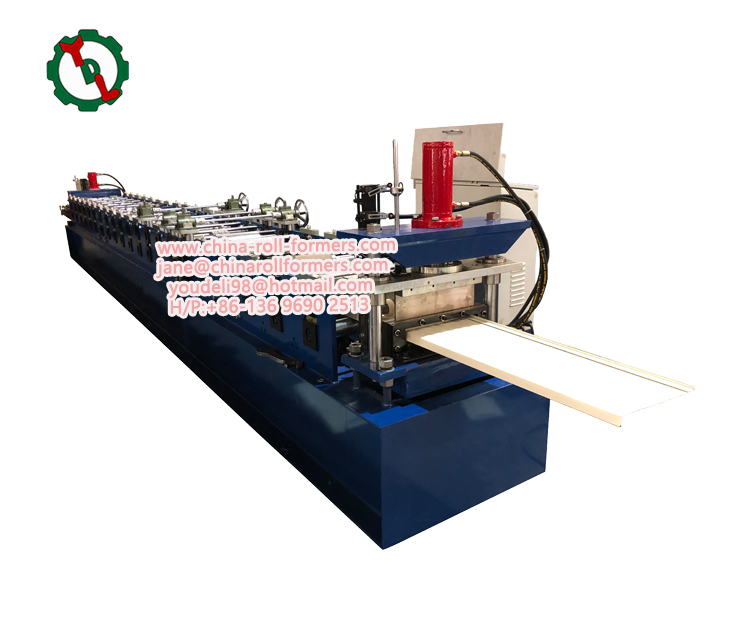

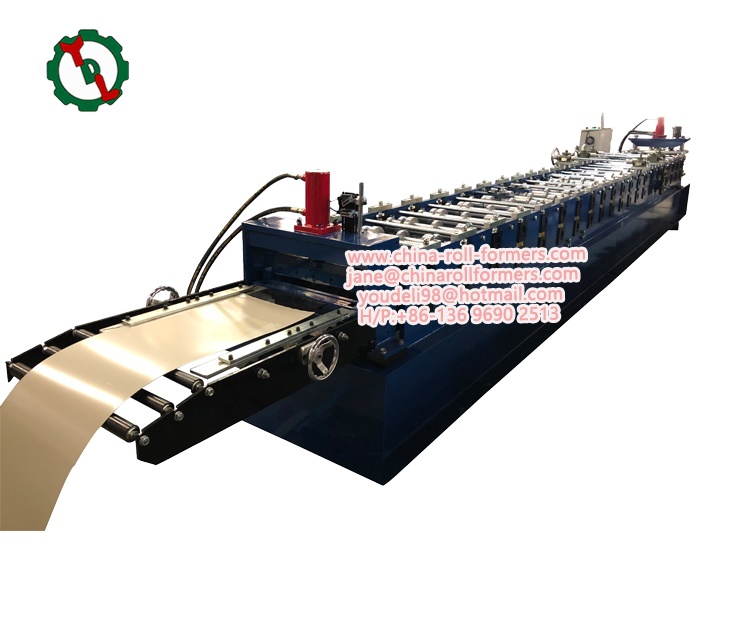

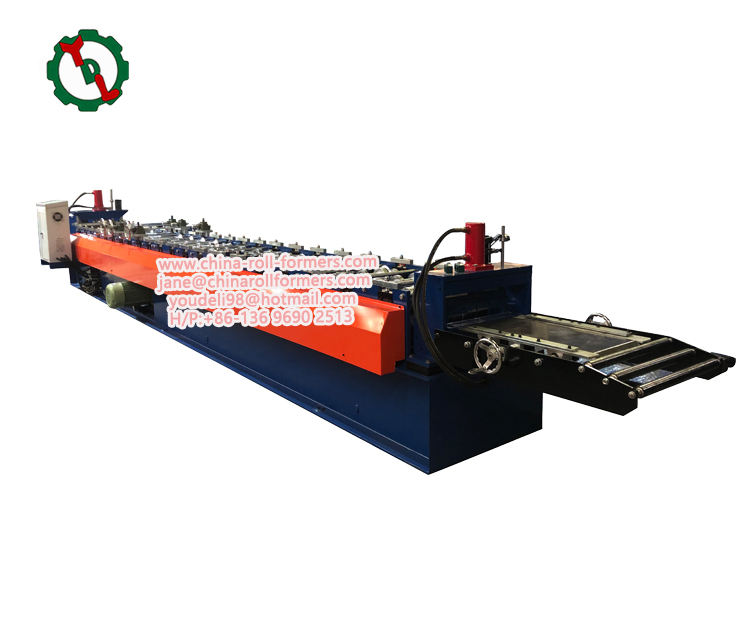

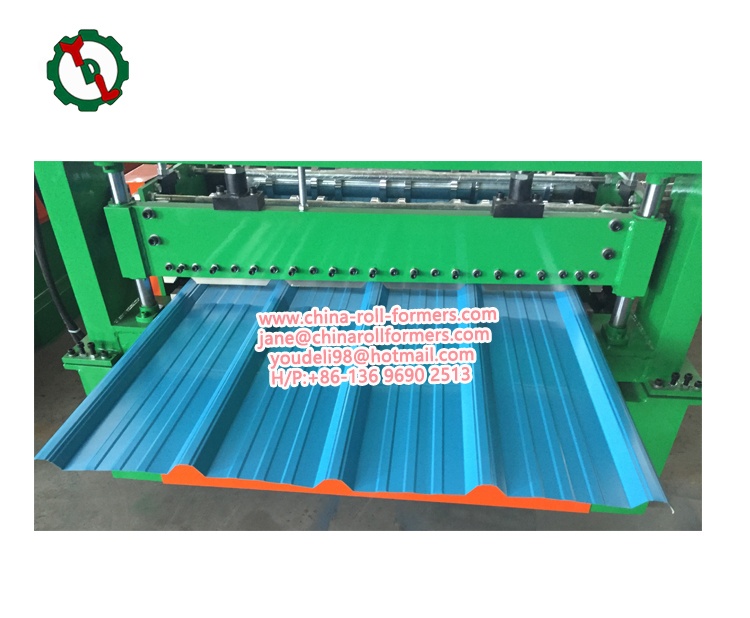

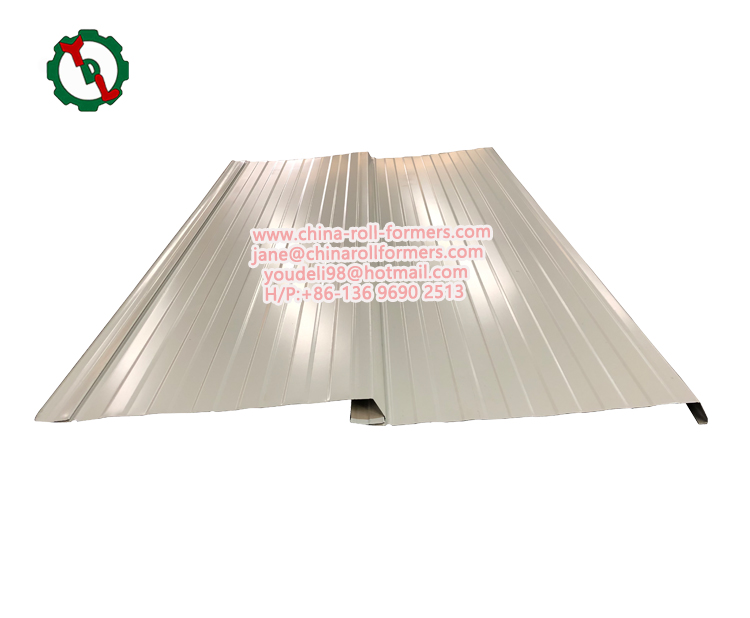

The Lock Lap Roof Roll Forming Machine is a special purpose mechanical equipment used to manufacture roof panels or roof panels. These panels are used on roofs of buildings to provide protection and waterproofing. Here are some details about some features and working principle of Locking Lap Roof Roll Forming Machine:

Features:

- Multi-Material Applicability: Locking Lapping Roofing Roll Forming Machine is capable of processing many different types of materials, including metals (such as aluminum, steel, copper), plastics and other composite materials, to suit different project requirements.

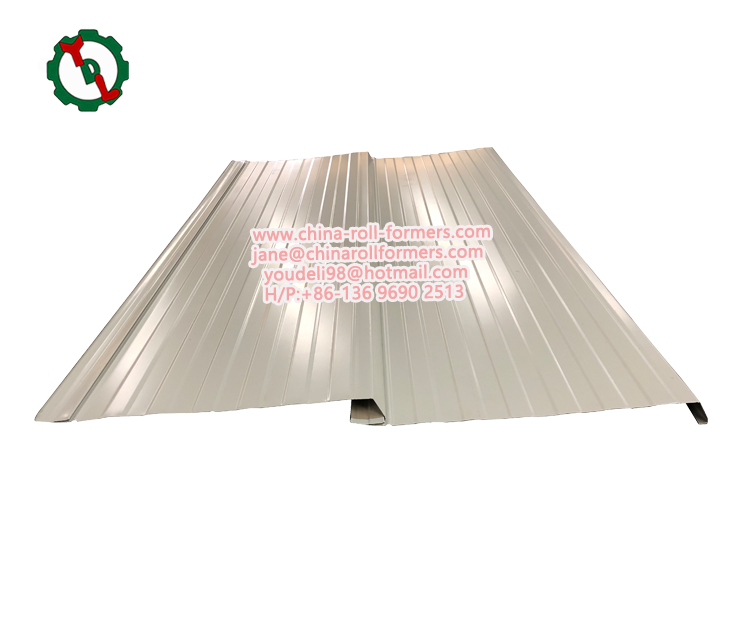

- Versatility: Lock-lap roof roll forming machines can manufacture roof panels in a variety of shapes and sizes, including lock-lap, tile, and corrugated, among others. This makes them ideal for accommodating a variety of architectural designs.

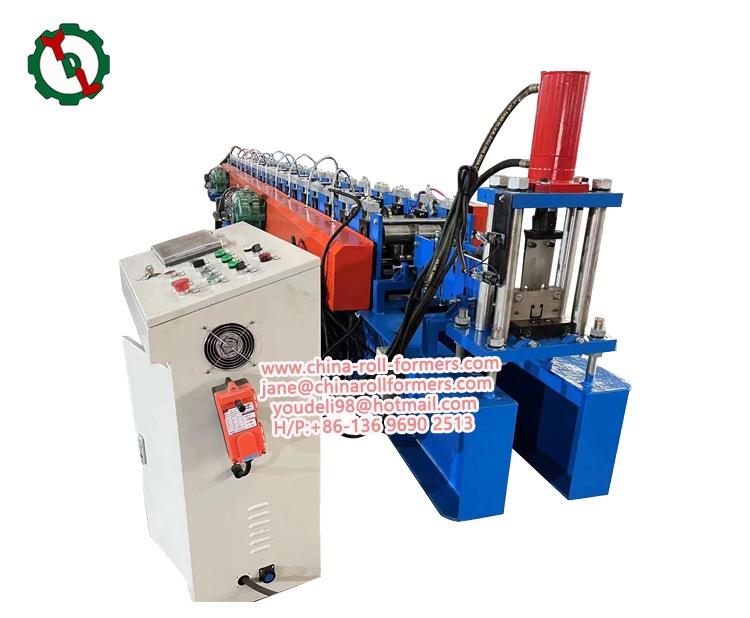

- Automation and Efficiency: Locking Lapping Roofing Roll Forming Machine has a highly automated operation, which can quickly and accurately manufacture a large number of roof slabs, improving production efficiency.

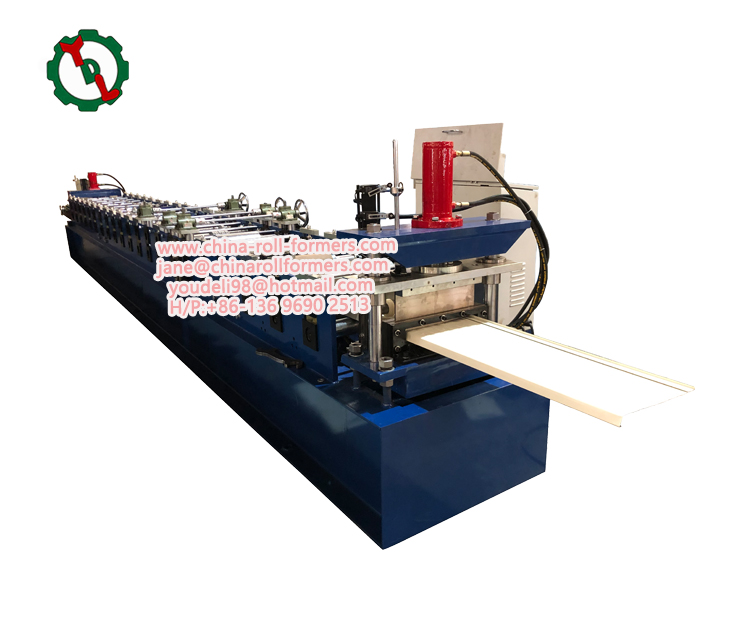

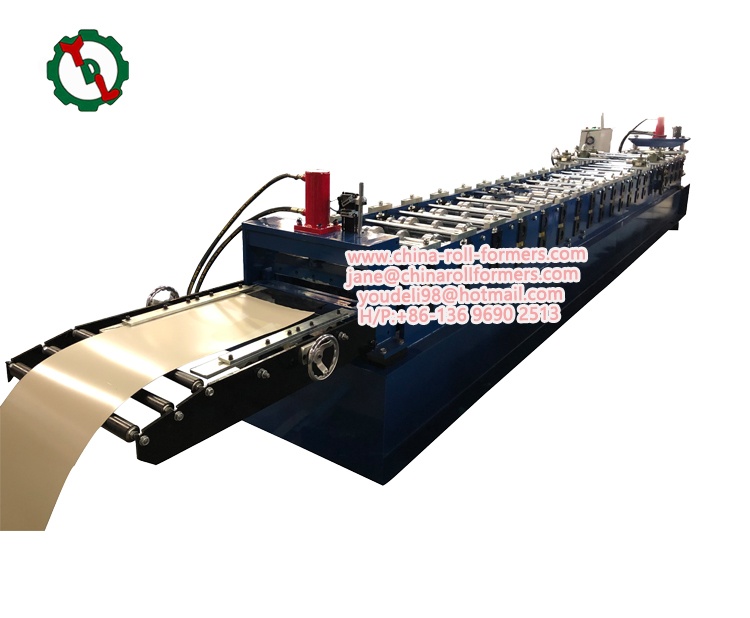

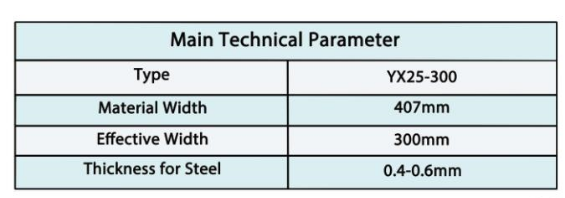

- Customization Capability: Lock-lap roof roll formers have flexible design options and can be customized to the specific requirements of a project, including varying lengths, widths and thicknesses.

- Safety: The equipment is equipped with safety features such as emergency stop buttons and safety doors to ensure the safety of operators during operation.

working principle:

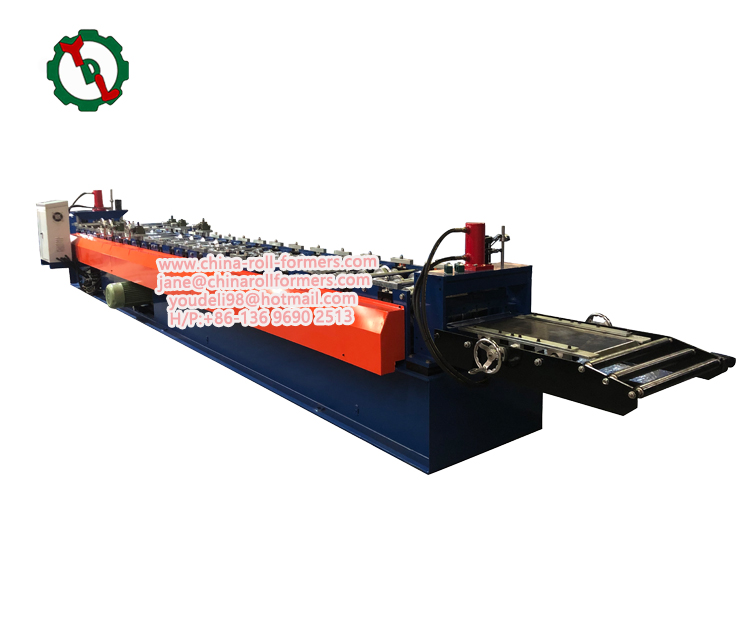

The principle of operation of a lock-lap roof roll forming machine involves feeding raw material (usually coil or sheet) into the machine, which is then formed into the desired roof shingle shape by a series of rollers and dies. The process includes steps such as bending, rolling, cutting, and locking the lap. The machine works through the raw material step by step to eventually produce a high quality, consistent roof slab.

In summary, lock lap roof roll forming machines are a key piece of construction equipment used to manufacture roof panels, they play an important role in construction projects, providing protective, waterproof and aesthetically pleasing roof solutions.

Application

Locking lap roofing roll forming machines are used in a wide range of applications in the construction industry, mainly for the manufacture and finishing of roof panels for protection, structural support and aesthetics. The following are some of the main applications of lock lap roofing roll formers:

roof manufacture

wall fabrication

structural support

decoration and exterior

Special Purposes: Lock-lap roofing roll forming machines can also be used to produce panels with special uses such as solar roof panels, green roof panels, etc. to meet the demands of sustainable construction and energy efficiency.

industrial and commercial facilities

Customized Projects: Lock-lap roofing roll formers have flexible design options so they can be customized to specific project requirements, including panels of different sizes, shapes and colors.