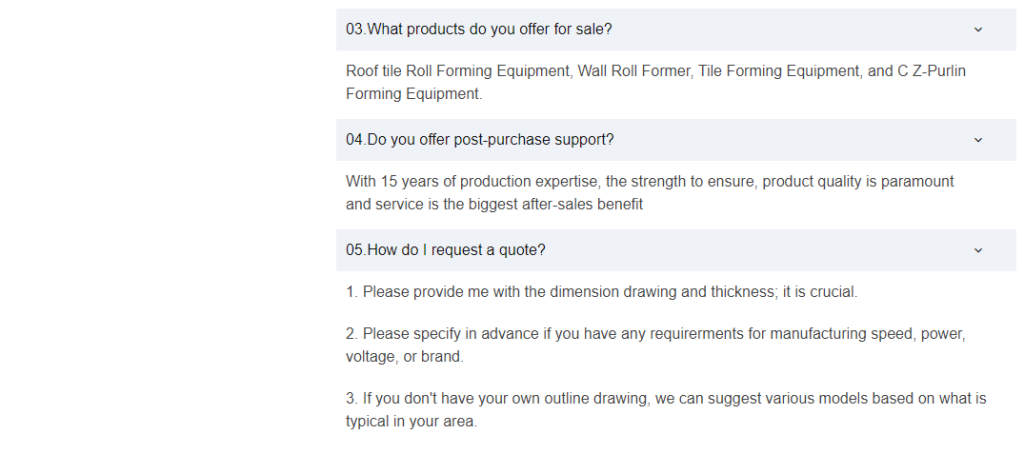

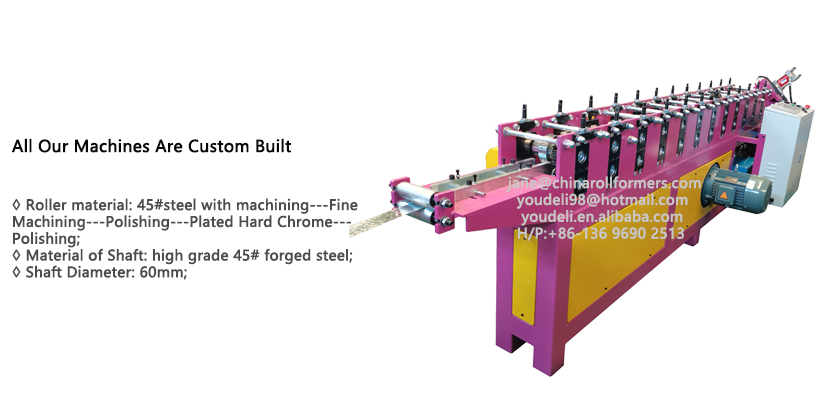

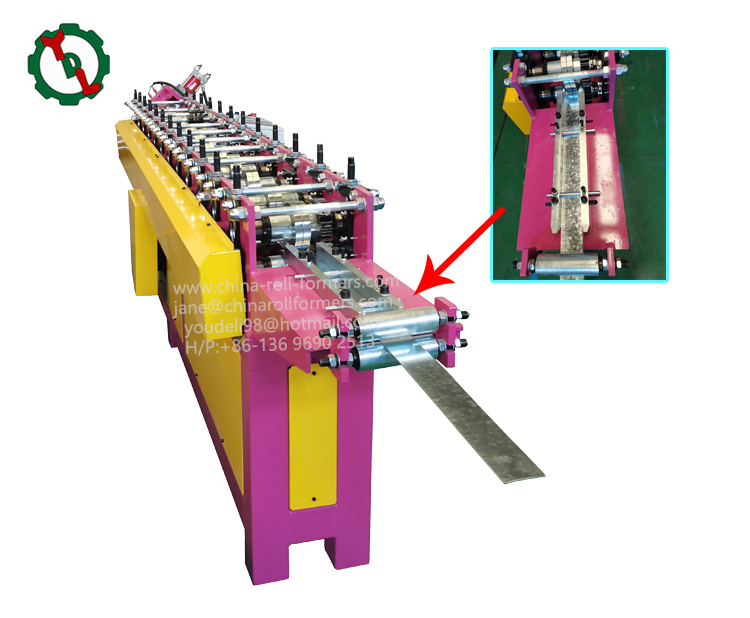

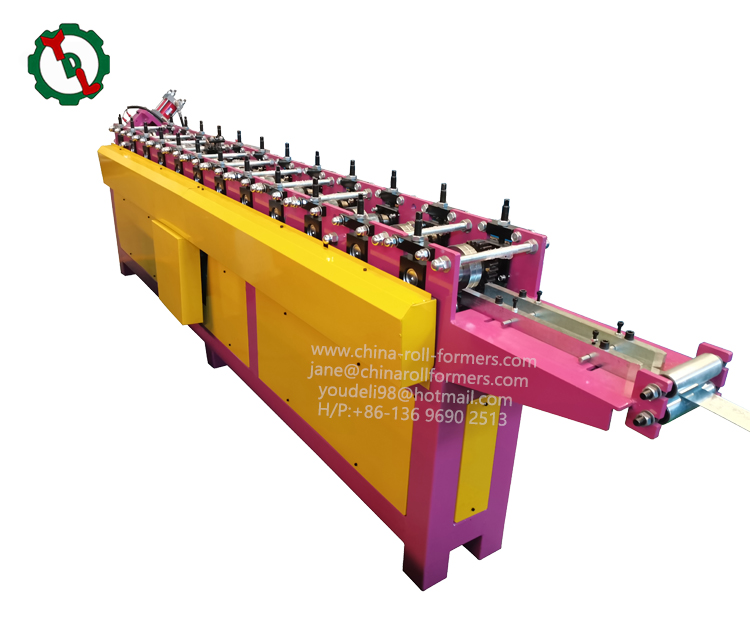

Metal Carrying Channel Purlin Machine Products Description:

The Channel Rolling Machine is a versatile and essential tool in metalworking, designed to efficiently roll and bend metal channels into various shapes and curves. The met、al carrying channel is an essential component in construction and building projects, providing support and structure for electrical wiring, piping, and various mechanical and technological systems. To produce this critical component, metal carrying channel roll forming machines are necessary.

Advantages

The channel rolling machine is a versatile and efficient tool designed for rolling and bending metal channels with precision and ease. Its key features include:

- High Precision: The machine is equipped with advanced controls and rollers that ensure precise bending of metal channels, allowing for accurate and consistent results.

- Variable Geometry: It can accommodate a wide range of channel sizes and shapes, making it suitable for a variety of applications across different industries.

- Ease of Use: The machine is designed for user-friendly operation, with intuitive controls and settings that make it easy to set up and operate.

- High Efficiency: It can process metal channels quickly and efficiently, helping to streamline production and reduce labor costs.

- Durable Construction: Built with high-quality materials, the machine is durable and reliable, ensuring long-term performance and minimal maintenance requirements.

- Versatile Applications: From construction and manufacturing to automotive and aerospace industries, the machine can be used for a wide range of applications that require curved metal channels.

- Safety Features: It is equipped with safety features such as emergency stop buttons and protective covers to ensure safe operation for the user.

- Customization Options: Depending on the specific requirements of the application, the machine can be customized with additional features or accessories to enhance its functionality.

Aplication

The channel rolling machine is widely used in various industries for rolling and bending metal channels to create curved or angled shapes.

Its applications include:

- Construction: They are used to fabricate structural components for buildings, bridges, and other infrastructure projects.

- Manufacturing: These machines are used in the manufacturing industry to create curved metal channels for conveyor systems, machinery, and equipment.

- Automotive: Channel rolling machines are used to produce curved metal channels for automotive frames, exhaust systems, and other components.

- Aerospace: In the aerospace industry, these machines are used to fabricate curved metal channels for aircraft structures and components.

- Shipbuilding: They are used in the shipbuilding industry to create curved metal channels for ship structures and fittings.

- Furniture: These machines are used in the furniture industry to create curved metal channels for furniture frames and decorative elements.

- Art and sculpture: Channel rolling machines are used by artists and sculptors to create curved metal channels for art installations and sculptures.

- HVAC: In the HVAC industry, these machines are used to fabricate curved metal channels for ductwork and ventilation systems.

- Energy: They are used in the energy industry to create curved metal channels for pipelines and other infrastructure.

- Agricultural machinery: These machines are used in the agricultural machinery industry to create curved metal channels for equipment frames and components.

Main Feature

1.Reasonable design, compact form, high accuracy, high efficiency, flexible and convenient adjustment.

2.Automated coil parameter detection, one-key coiling, one-key material taking, and automated alignment adjustment are some of the features.

3.Automated double palletizer switching, automated beat detection, precise computation, safe, and dependable.

4.The manufacture of each component is monitored and controlled, and the manufacturing process of the machine is produced strictly in compliance with the standard requirements of the machine.

5.Collaboration with renowned manufacturers both domestically and internationally, the creation and extension of a professional technical team, the introduction of world-class leveling line technology, and the provision of users with high-end, effective automatic plate processing equipment.

6.The main engine’s bearings and rails are imported brands with cutting-edge lubrication systems and long service lives.

7.The mechanical parts are made by well-known domestic and international manufacturers, and the electrical components are high-end imports.

Wrking Principle

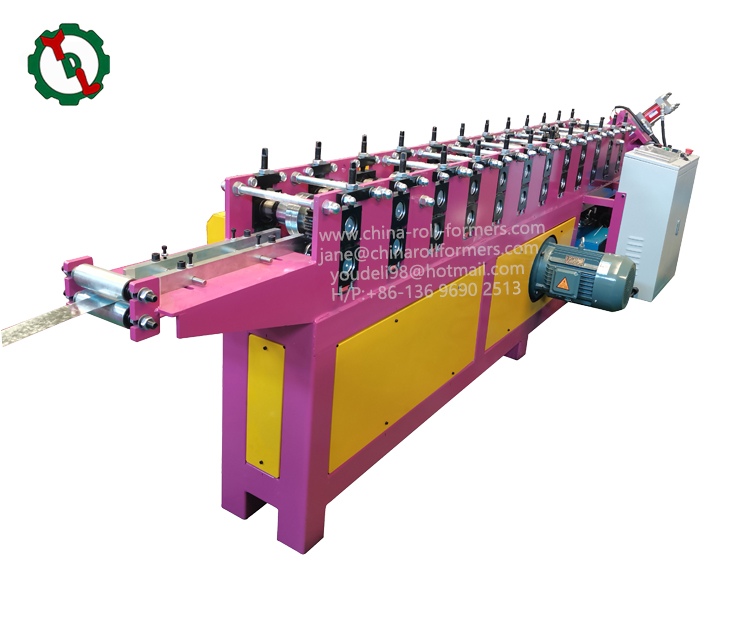

A metal carrying channel roll forming machine is a type of equipment that uses roll forming technology to shape metal sheets into various profiles. The machine operates by passing sheets of metal through a series of rollers, each with a designated profile, to shape the metal into the desired form. This technology allows for precision, consistency, and speed in the manufacturing process, resulting in high-quality and efficient production of metal carrying channels.

The metal carrying channel roll forming machine is designed to handle various types of metals, including galvanized steel, stainless steel, and aluminum. The machine’s versatility enables manufacturers to produce metal carrying channels of different dimensions, thicknesses, and shapes, depending on the project’s needs. The machine’s electronic control system ensures precise and consistent measurements, reducing wastage and increasing productivity.

The metal carrying channel roll forming machine’s efficiency and cost-effectiveness have made it a popular choice among metalworking industries. The machine’s automated operation requires minimal labor, reducing production costs associated with manual labor significantly. Additionally, the machine’s ability to produce large quantities of metal carrying channels in a relatively short time frame results in faster production and delivery times, increasing customer satisfaction and revenue.

The metal carrying channel roll forming machine’s technology has continued to evolve, with newer models featuring increased automation, better accuracy, and improved safety features. Some newer models feature computerized controls, touch screen interfaces, and automatic material feeding systems, further increasing the machine’s efficiency and accuracy.

A metal carrying channel roll forming machine is an important piece of equipment in the construction industry that is used to manufacture metal carrying channels. These channels are used to support and hold electrical wiring, pipes, ductwork, and other items inside buildings.

The roll forming process involves feeding metal coils through a series of rollers that gradually shape the metal into the desired profile. This process is highly automated and can produce large quantities of metal carrying channels quickly and efficiently.

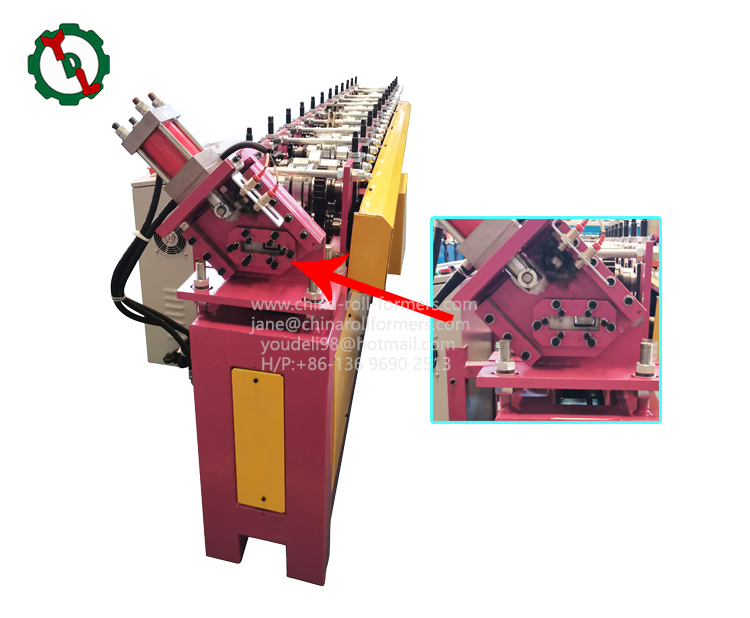

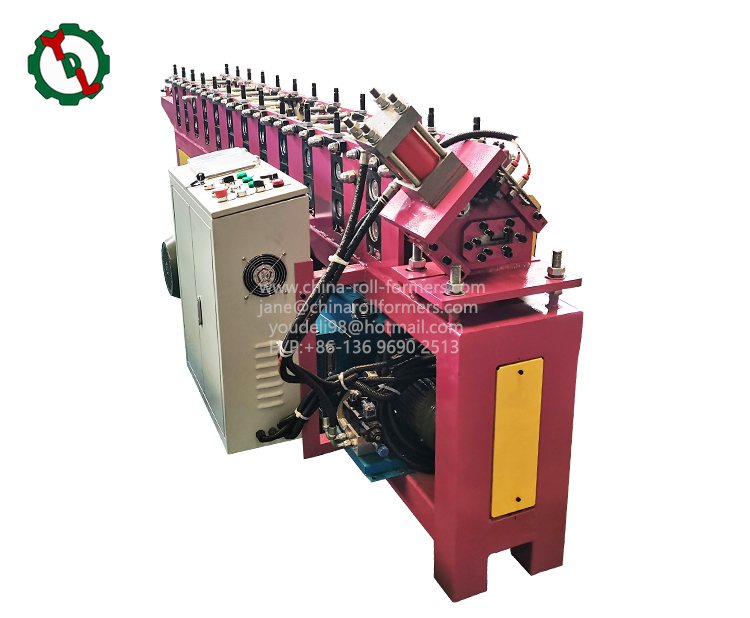

The machine is typically equipped with a range of features, such as a decoiler to handle metal coils, a cut-off shear to cut the finished products to length, and a control system to adjust the speed and other settings of the machine. The rollers themselves can be customized to produce specific shapes and sizes of metal carrying channels to meet the specifications of the project.

One of the advantages of using a metal carrying channel roll forming machine is that it can produce products of consistent quality and size. This is important in construction projects where exact measurements and specifications are required. The machine’s high level of automation also reduces the risk of errors and improves the speed and efficiency of production.

In addition to consistency and efficiency, the machine’s versatility is another advantage. It can produce a wide range of metal carrying channels, from simple U-shaped channels to more complex profiles with multiple bends and twists. This flexibility allows construction companies to produce customized solutions for their projects, which can enhance the functionality and visual appeal of the finished building.

In conclusion, the metal carrying channel roll forming machine is an indispensable piece of equipment in modern metalworking industries. With its advanced technology, precision engineering, and versatility, it enables companies to produce high-quality metal carrying channels that meet the exact requirements of their projects, while also improving the speed and efficiency of production. Its versatility, efficiency, and cost-effectiveness make it an ideal choice for manufacturing metal carrying channels of different dimensions and shapes. As technology advances, the machine’s capabilities continue to improve, making it an increasingly essential part of the metalworking industry.

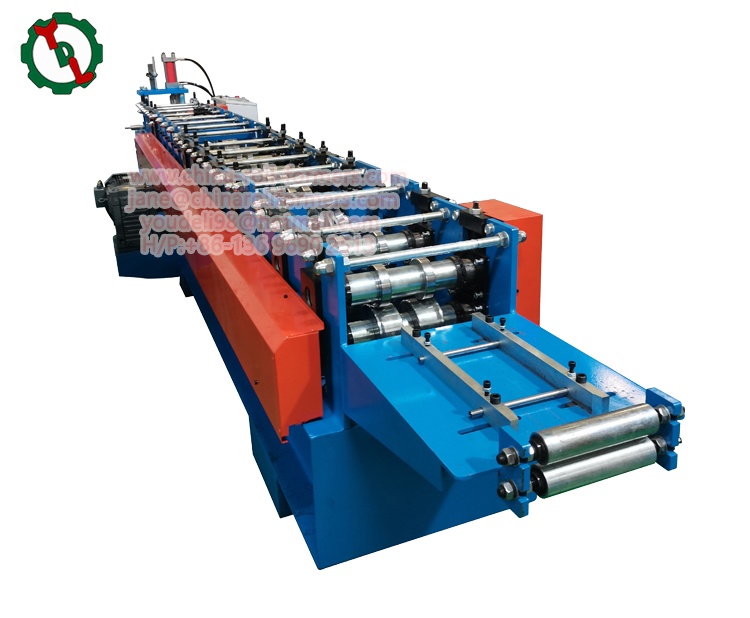

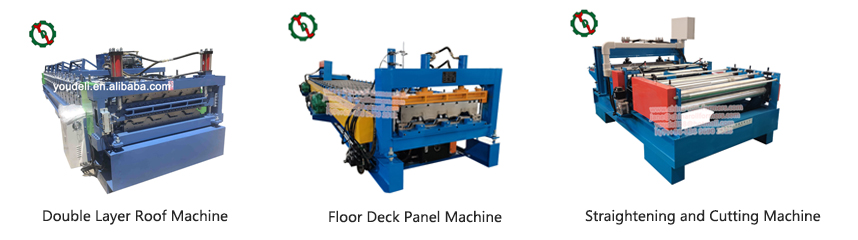

Company Profile

Xiamen YOUDELl lndustrial Co., Ltd is a professional manufacturer and exporter who are concerned with more than 15 years of experience in the design, development and manufacture of Cold Roll Forming Machines and Roofing systems accessories, Punching Modules/Dies and Hardware Products.

Such as Standing Seam Roofing Machines, Automatic Smooth/Crimping Roofing Curving Machines, C/Z Purlin Machines, C/U Profile Light Steel Framing Forming Machines, Tile Roofing Machines, Wall/Siding Forming Machines, Floor Decking Machines, Flattening-Slitting-Cutting Machines, Roofing seaming Machines, Al Clips, Steel Roofing Clips, Shear Studs and Other Related Products.

We are located in a nice island City–Xiamen with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world. Such as Korea, Philippines, Malaysia, Singapore, Indonesia, Thailand, India, Turkey, UAE, lran, Lebanon, Sri Lanka, Kazakhstan, Libya, Uganda, Canada, Brazil, Bolivia, Australia, etc. over 30 countries.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. Bearing in mind the service tenet of “Pour your satisfaction with your heart, YOUDELI is guided by the Enterprise Development Philosophy of “honesty first, honesty and pragmatism. YOUDELI lndustrial sincerely welcomes friends from all walks of life to visit the company,

study, guidance, we look forward to your arrival!

Products Parameters

| Model NO. | YX13-37 |

| Size | 4000*850*1220mm |

| Weight | 1500KGS |

| Voltage | 220V/60HZ.3PH/ or as Request |

| Motor Power | 5.5KW |

| Hydraulic Power | 2.2KW |

| Thickness | 0.5-1.0mm |

| Forming Steps | 12steps |

| Working Speed | 18m/min |

| Height of Bottom Board | 13mm |

| Effective Width | 37mm |

| Material Width | 61mm |

| Tolerance for cutting,forming | +2.0mm |

| Straightness | 2mm/m |

| Material | GI, PPGI, Aluminum, Stainless Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines |

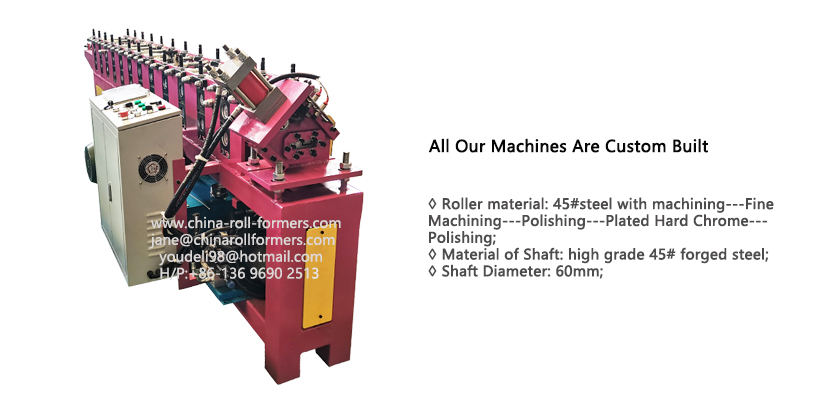

| Roller Material | Cr12 mold steel with heat treatment, fine machining, Plated hard chrome, Polished and Coated Rubber for all the rollers |

| Material of shaft | High grade 45# forged steel |

| Purchase Qty: | 1 Set |

| Port: | Xiamen China |

| Payment Terms: | L/C, T/T |

| Fob: | Inquiry Price |

| Certification: | CE, ISO |

| Condition: | New |

| Customized: | Customized |

| Automatic Grade: | Automatic |

| Transmission: | Motor and Chain For Driving |

| Means of transport: | By sea as full container |

| Packing: | Standard for export |

| Delivery time: | 60 days |

Our Certificate

How to reflect the precision and quality in the design of metal carrying channel roll forming machines?

In the design of the metal carrying channel roll forming machines, the accuracy and quality are mainly reflected in the following aspects: Processing precision control: The metal carrying channel roll forming machines uses high-precision molds and cutting tools to ensure the accuracy and consistency in the processing process. The equipment has an advanced positioning and guiding system, which enables accurate molding operations and avoids machining errors and deformation.

- Quality inspection link: The metal carrying channel roll forming machines is equipped with a comprehensive quality inspection link, including online inspection and offline inspection. The on-line inspection system can monitor the parameters in the processing process in real time, such as size, shape, material thickness, etc., to ensure that the processing quality meets the requirements. The off-line inspection system carries out a comprehensive quality inspection on the molded groove roller, including surface quality, hardness, metal logr aphic structure, etc., to ensure that the product quality is qualified.

- Process optimization: In the design process of the metal carrying channel roll forming machines, the process optimization will be carried out to obtain high quality products. Through the in-depth research and practice of the molding process, the key process parameters and operation flow are determined to achieve the optimal configuration of the process flow and improve the quality and stability of the product.

- Selection of materials and components: High-quality materials and components are selected in the design of the metal carrying channel roll forming machines to ensure the overall quality and performance of the equipment. For example, the selection of high-strength, high-wear resistance of steel as the roller material, improve the service life of the roller and the ability to maintain accuracy. In addition, the selection of high-quality hydraulic and electrical components to improve the reliability and stability of the equipment also helps to ensure product quality.

- Equipment debugging and calibration: After the manufacturing of the Metal carrying channel roll forming machines, it is necessary to carry out a comprehensive debugging and calibration to ensure that the accuracy and quality of the equipment meet the requirements. This includes precision commissioning of mechanical components, calibration of hydraulic and electrical systems, and inspection of machining accuracy. Through these steps, you can ensure that the equipment has reached a high quality standard before it is put into use.

Related Products

Cargo Loading

Why choose us?

1.Upon request, we can design and build any kind of roll forming machine.

2. This is a very dependable piece of machinery. We have more than 13 years of experience.

3. This kind of equipment has the best quality and price. It is easy to use and provides precise measurement.Depending on the requirements of the clients, we can create special devices.

4.We may provide technical support, production, installation, debugging, and maintenance services to all customers.

5. Our product has a strong reputation and has been exported to many places due to its high quality and competitive cost.