| Purchase Qty: | 1 Set |

| Port: | Xiamen China |

| Payment Terms: | L/C, T/T |

| Fob: | Inquiry Price |

| Certification: | CE, ISO |

| Condition: | New |

| Customized: | Customized |

| Automatic Grade: | Automatic |

| Transmission: | Motor and Chain For Driving |

| Means of transport: | By sea as full container |

| Packing: | Standard for export |

| Delivery time: | 60 days |

1

Company Profile

2

Products Description

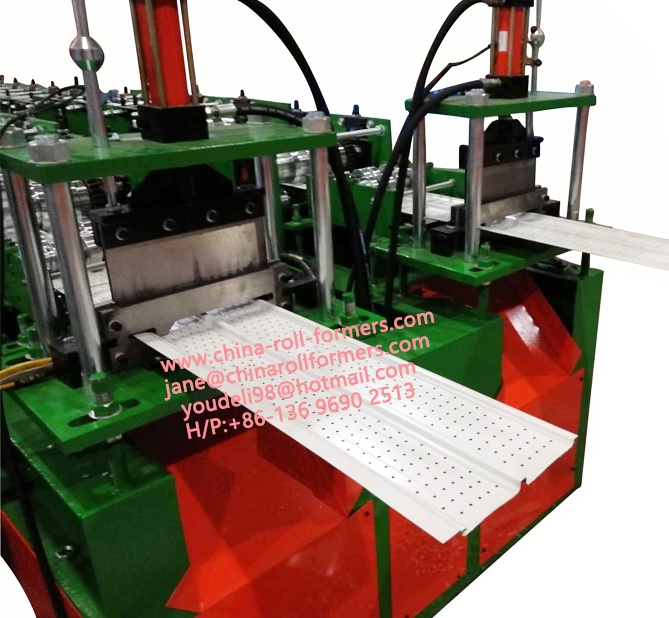

| Model NO. | YX38-290-530 |

| Size | 2500*1400*1300mm |

| Weight | 1800KGS |

| Voltage | 220V/60HZ/3PH |

| Forming Steps | 9steps |

| Height of Roofing | 38mm |

| Effective Width of Roofing | 290mm-530mm |

| Material Width | 394mm-634mm |

| Forming Aluminum Thickness | 0.6-1.2mm |

| Forming Steel Thickness | 0.5-1.0mm |

| Tolerance | ±2mm |

| Material | GI, PPGI,PPGL, Aluminum, Stainless Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines |

| Material of shaft | High grade 45# forged steel |

3

Products Description

Roller material: 45# steel with machining—Heat Treatment—Fine Machining— Polishing—Plated Hard Chrome—Polishing;

How long it takes to produce a roof and which workers are needed

The time it takes to produce a roof and the type of workers required can be affected by a number of factors, including the size, structure, materials and construction conditions of the roof. Here is a general overview:

1、production time

- Design planning: Before starting production, it is usually necessary to carry out detailed design planning, including the size, shape, structure and material selection of the roof. The timing of this phase depends on the complexity of the design and the number of modifications required.

- Material preparation: Once the design is completed, the required materials need to be prepared. This includes buying steel, waterproofing, insulation, etc., and may take a certain amount of time to transport and store.

- Production and installation: The production and installation of the roof is the most time-consuming stage. For the steel structure roof, the steel skeleton needs to be made and installed, and waterproof treatment and insulation layer need to be laid. The timing of this phase depends on the size of the roof, the complexity of the structure and the efficiency of the construction team.

Overall, the time it takes to produce a roof can vary from weeks to months, depending on a combination of the above factors.

2、 Required workers

- Construction workers: Construction workers play a vital role in roof construction. They set up scaffolding, move materials, install steel frames and roof tiles.

- Welders: In the production and installation process of steel structure roof, welders are essential. They are responsible for the precise cutting, splicing and welding of the steel to ensure that the entire structure is strong and stable.

- Electrician: Electrician in the roof construction is mainly responsible for the installation of electrical facilities, such as wires, lamps, sockets and so on. They also need to ensure that these facilities are coordinated with the safety and waterproofing of the roof structure.

- Technical workers: technical workers are responsible for a variety of accurate measurement, cutting and splicing work in roof construction. They also need to perform maintenance and maintenance on the roof structure to ensure the stability and safety of the entire structure.

In addition, depending on the needs of the project, other types of professionals may be required, such as safety supervisors, quality inspectors, etc.

To sum up, the time it takes to produce a roof depends on a variety of factors, and the types of workers required mainly include construction workers, welders, electricians and technicians. In actual construction, reasonable arrangements and deployments should be made according to specific needs and conditions.

The materials required mainly include the following aspects:

1、the main structural materials

- Steel: used to manufacture the main frame, support structure and transmission parts of the machine. The steel needs to have good strength and rigidity to ensure the stability and durability of the machine. For example, the main frame of the machine may be welded with steel plates and stress-relieved to improve its overall strength and stability.

- High quality roller materials: such as S45C steel, which is heat treated and hard chrome coated on the surface, for forming and pressing sheet metal.The selection and treatment of roller materials is crucial to ensure the quality and accuracy of the product.

2、transmission and control system materials

- Motor: Provide the power required for the operation of the machine.The selection and configuration of the motor should be determined according to the power requirements and operating efficiency of the machine.

- Transmission parts: such as gear box, chain and drive shaft, etc., used to transfer the power of the motor to each working part.These parts need to have good wear resistance and reliability to ensure the stable operation of the machine.

- Control system: PLC (Programmable logic controller) is usually used for control to improve the degree of automation and operation efficiency of the machine.PLC brands may include Panasonic, Mitsubishi, etc.

3、forming and cutting materials

- Molding mold: customized according to the desired shape and specifications of the roof panel, used to press the metal sheet to form.The design and manufacturing accuracy of the molding mold is crucial to ensure the molding quality of the product.

- Cutting blade: used to cut the metal sheet after forming.Cutting blades are usually made of high-strength materials such as Cr12 to ensure the accuracy and efficiency of cutting.

- Other auxiliary materials

- Hydraulic oil: used for the operation and transmission of hydraulic systems.The choice of hydraulic oil should be determined according to the working pressure and temperature range of the system.

- Lubricant: used to reduce friction and wear during the operation of the machine, improve the operating efficiency and life of the machine.

- Electrical components: such as wires, cables, switches, indicators, etc., used for electrical connection and control of the machine.

4

Our Certificate

Five characteristics of steel:

1, the common “several” word purlin structure, effectively deal with the greenhouse temperature difference formed by the drip dew phenomenon, can effectively deal with the greenhouse in winter dew question.

2, hot dip galvanized steel plate material, good corrosion resistance, longer life, normal service life of not less than 15 years.

3, the appearance is beautiful and modern, the overall structural strength is greater, and the bearing capacity can be far greater than the previous steel pipe structure.

4, all the greenhouse skeleton selection of stereotyped equipment production, convenient device, no solder joints, time will not rust.

5, 10 meters within the span of the skeleton center without pillar, greatly increasing the farming area, saving labor, increasing efficiency.

Choose our strengths

- Experience: We have 15 years of industry experience and expertise to provide you with high quality services.

- Efficient production capacity: YOUDELlhas advanced production equipment and perfect production process. We adopt modern production management methods to ensure that every production link is optimized, thereby improving production efficiency and quality.

- Innovative thinking: We have innovative thinking and advanced scientific and technological means to provide customers with better solutions.

- Professional team: YOUDELlhas a professional research and development team dedicated to the development of efficient, reliable and intelligent equipment. We use the most advanced technology and processes,We have a professional team that can provide you with a full range of services and support.

- Quality service: YOUDELlcompany always adhere to the customer-centric service concept. We provide a full range of pre-sale, sale, after-sales services to ensure that customers in the purchase and use of products in the process of timely help and support.

- Reasonable prices: We offer reasonable prices and fees to make your investment worthwhile.

- Integrity management: We adhere to the concept of integrity management, and can establish long-term stable cooperative relations with customers.

- Good brand image: YOUDELlhas a good brand image and reputation in the field of roofing machinery and related equipment. We pay attention to product quality and service, won the trust and recognition of customers, and set up an excellent image in the market.

5

Cargo Loading

6

Why Choose Us?

- Upon request, we can design and build any kind of roll forming machine.

- This is a very dependable piece of machinery. We have more than 15years of experience.

- This kind of equipment has the best quality and price. It is easy to use and provides precise measurement.Depending on the requirements of the clients, we can create special devices.

- 4.We may provide technical support, production, installation, debugging, and maintenance services to all customers.5.

- Our product has a strong reputation and has been exported to many places due to its high quality and competitive cost.

7

Sample Chamber

FAQ

01.How can I pick the best machine for me?

1. A machine doesn’t only show a few images to demonstrate its capabilities

2. A machine ought to have images and videos of a comprehensive production and assemblysystem. Making sure a company has a thorough after-sales service system is essential whenselecting one with a factory.

02.How can we ensure quality, then?

Before mass manufacturing, there is always a pre-production sample; before shipment, there isalways a final inspection.

03.What products do you offer for sale?

Roof tile Roll Forming Equipment, Wall Roll Former, Tile Forming Equipment, and C Z-PurlinForming Equipment.

04.Do you offer post-purchase support?

With 15 years of production expertise, the strength to ensure, product quality is paramount andservice is the biggest after-sales benefit.

05.How do I request a quote?

1. Please provide me with the dimension drawing and thickness; it is crucial.

2. Please specify in advance if you have any requirements for manufacturing speed, power.voltage, or brand.

3. lf you don’t have your own outline drawing, we can suggest various models based on what istypical in your area.