Shutter Door Roll Forming Machine

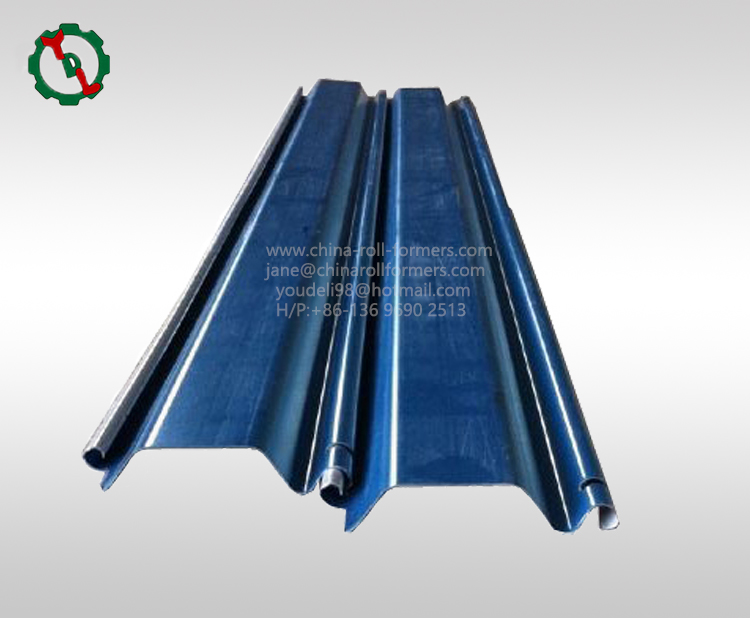

A shutter door roll forming machine, commonly used in the manufacturing of roller shutters for commercial, industrial, and residential purposes, is a specialized piece of equipment designed to produce high-quality, durable shutter doors. These machines automate the process of cutting, bending, and perforating metal sheets into the final shutter slats, ensuring precision and efficiency in production.

Features and Functions

- Automated Operation: Fully automated operations reduce manual labor and minimize errors, ensuring consistent product quality.

- Customization Capability: Allows for the creation of shutters in various sizes and designs, catering to custom specifications.

- Integrated Cutting Mechanism: The built-in cutting unit provides clean and precise cuts without the need for separate processing, enhancing efficiency.

- Easy Operation Interface: Features a user-friendly interface, making it easy for operators to manage production settings and troubleshoot issues.

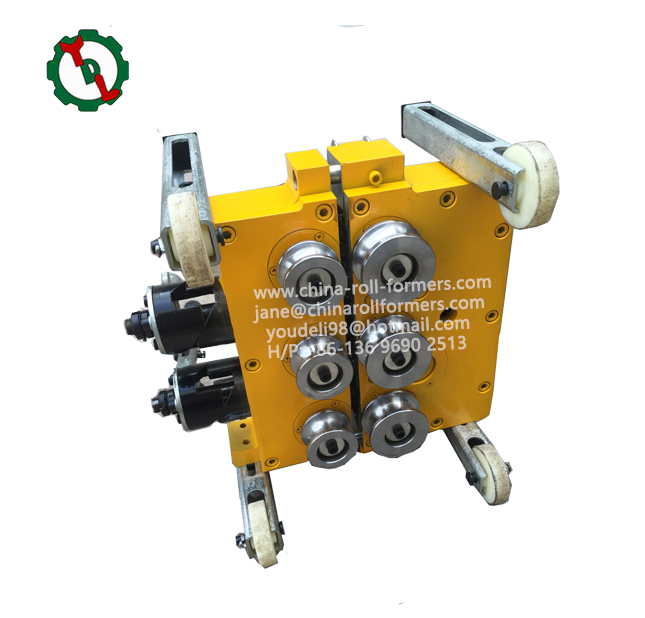

Technical Specifications

- Materials Processed: Capable of handling various materials such as steel, aluminum, and galvanized sheets.

- Thickness Range: Designed to work with material thicknesses from 0.5mm to 1.2mm, accommodating different shutter strength requirements.

- Production Speed: Offers a high production speed, typically ranging from 10 to 25 meters per minute, enhancing manufacturing throughput.

- Control System: Equipped with an advanced PLC (Programmable Logic Controller) for precise control over production parameters and easy customization.

- Power Requirements: Operates on standard industrial power supply voltages, with specific adaptations available for different countries.

Advantages of Using a Shutter Door Machine

- Increased Productivity: Automates the production process, significantly increasing manufacturing speed and volume.

- High-Quality Output: Ensures the production of uniform, high-quality shutter doors with excellent durability and aesthetic appeal.

- Cost Efficiency: Reduces labor costs and material wastage, contributing to overall cost savings in shutter door production.

- Versatility: Capable of producing a wide range of shutter door types and sizes, offering manufacturers flexibility in their product offerings.

- High Efficiency: The machine significantly reduces production time and labor costs compared to manual fabrication methods.

- Consistent Quality: Automated processes ensure uniformity and consistency in the finished shutter doors, meeting quality standards.

- Cost-Effective: Despite its initial investment, the machine offers long-term cost savings through increased productivity and reduced material waste.

- Customization: The machine allows for customization of shutter door designs, enabling manufacturers to cater to specific customer preferences.

Applications

Shutter door machines are essential in the production of roller shutters for various applications, including:

- Commercial establishments such as shops, warehouses, and garages.

- Residential buildings, providing security and insulation.

- Industrial settings, where sturdy and reliable doors are necessary for security and operational efficiency.

Conclusion

The Shutter Door Machine is a versatile and efficient solution for manufacturers looking to streamline their shutter door production process. With its robust construction, precision engineering, and advanced functionalities, the machine offers consistent quality, high efficiency, and cost-effective operation, making it a valuable asset for any shutter door manufacturing facility.

Shutter door roll formingmachine is a mechanical equipment that automatically or manually operates rolling shutter doors, often used in commercial and industrial buildings. It consists of a motor, a reducer, a drive shaft, a rolling shutter door, etc. According to the weight and size of the rolling shutter door, different models of Shutter door roll formingmachine can be selected.

Shutter door materials have a variety of choices, the following are several common materials and their characteristics:

- Aluminum alloy: Aluminum alloy shutter door appearance beautiful, durable, with good anti-theft performance and corrosion resistance, widely used in commercial and industrial fields. However, its sealing and thermal insulation performance is poor.

- Stainless steel: stainless steel curtain door has excellent corrosion resistance, rust resistance and easy cleaning, suitable for humid environment. Its appearance is modern, but the price is higher.

- Color steel plate: Color steel shutter doors are rich in color, strong plasticity, and have good thermal insulation and sound insulation effects. It is suitable for industrial plants, warehouses and other places that need fire prevention and anti-corrosion.

- PVC: PVC curtain door has the characteristics of light, waterproof, dustproof, etc., suitable for indoor and outdoor environment. Its price is relatively low, but the thermal insulation, sound insulation performance is general.

- Grid: grid curtain door has good ventilation and anti-theft effect, suitable for places that need a sense of transparency. But its production process is more complex, the price is higher.

When choosing a shutter door roll forming machine, the following aspects need to be considered:

- Door curtain size: Door curtain size has an important impact on the selection of motor. In general, the larger the curtain, the greater the motor power and torque required, and the suitable motor should be selected according to the size of the curtain when selecting the motor.

- Material: The selection of materials should consider lightweight, durable materials, so that even in special circumstances can play a high safety problem.

- Motor performance: The performance parameters of the shutter motor include specifications, models, functional characteristics, rated voltage, rated current, rated power, power frequency, etc., of which the choice of power is very important. To select the appropriate power of the rolling shutter motor according to the weight of the rolling shutter door body, the lifting force of the rolling shutter motor is generally required to be 2 times the weight of the door body.

- Structure and quality: Observe whether the structure of the electric shutter door is precise, the degree of lubrication is good or not, the heat dissipation of the electric shutter door is compared, and the whole gear rotation is adopted, without chain and belt, so as to enhance the overall life of the shutter door movement. Brand is also an indispensable factor, many small processing plants in order to reduce production costs, blindly reduce the material of accessories, at the same time the quality of the installation can not get the corresponding protection, as well as maintenance is the same, so customers should properly consider the brand of the enterprise when purchasing the shutter door.

Products Parameters

| Purchase Qty: | 1 Set |

| Port: | Xiamen China |

| Payment Terms: | L/C, T/T |

| Fob: | Inquiry Price |

| Certification: | CE, ISO |

| Condition: | New |

| Customized: | Customized |

| Automatic Grade: | Automatic |

| Transmission: | Motor and Chain For Driving |

| Means of transport: | By sea as full container |

| Packing: | Standard for export |

| Delivery time: | 60 days |

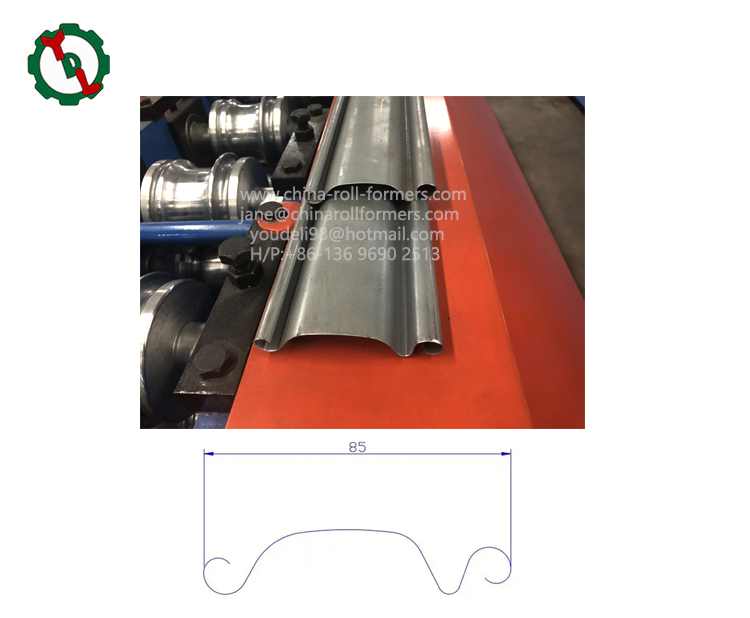

| Model NO. | JM85 |

| Size | 5600*1000*1400MM |

| Weight | 1550KGS |

| Voltage | 220V/60Hz,3PH/ or as Request |

| Hydraulic Power | 2.2KW |

| Main Motor Power | 4KW |

| Forming Steps | 14+3steps for reshape |

| Running Speed | 8-12m/min |

| Effective Width | 85mm |

| Feeding Material Width | 136mm |

| Material Thickness | 0.6-0.8mm |

| Thickness for common use and test | 0.6mm,0.8mm |

| Tolerance | ±2mm |

| Material | GI, PPGI, Aluminum, Stainless Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines |

| Material of shaft | High grade 45# forged steel |

Our Certificate

Why Choose Us?

1. Upon request, we can design and build any kind of roll formirng machine

2. This is a very dependable piece of machinery. We have more than 15 years of experience.

3. This kind of equipment has the best quality and price. Itis easy to use and provides precise measurement.

Depending on the requirements of the clients, we can create special devices.

4.We may provide technical support, production, installation, debugging, and maintenance services to all customers.

5. Our product has a strong reputation and has been exportted to many places due to its high quality and competitive cost.

Cargo Loading

Sample Chamber