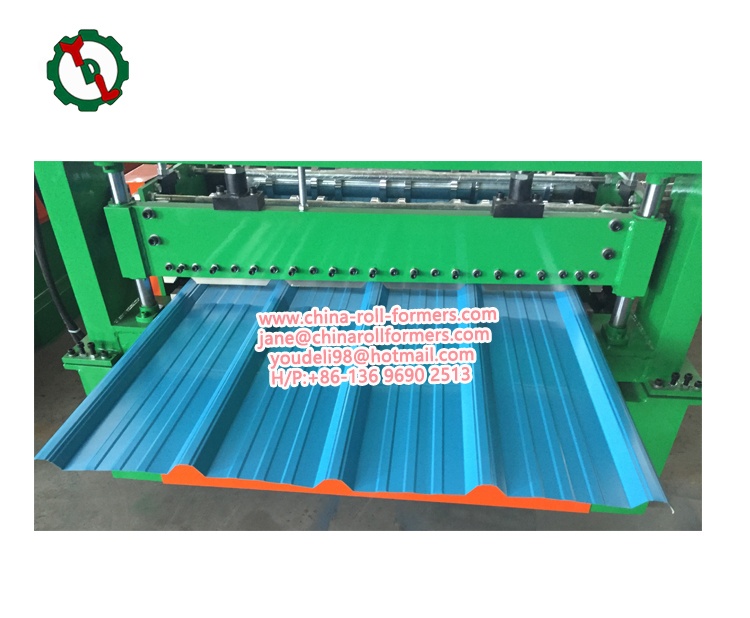

A crimping, curving machine is meant for use in the metal roofing trade. It helps in bending or crimping curving machine metal roof panels so they can contour the shape of the roof surface. Crimp bending machine allows customization of roof panels to different shapes of roofs with precision and efficiency. It also offers board types to suit a variety of building designs and roof structures.

Crimping Curving Machine features and capabilities

1. Bending ability: It can bend metal roof panels with standing seams. You may set the machine to match your panels to the shape and slope of your roof, ensuring correct installation.

2. Accuracy and Consistency: Machines for crimp bending have high precision capabilities for consistent and even metal panel bending. The precise degree of bending allows the panels to fit together flawlessly.

3. Use in Different Materials: It can be applied under any type of metallic material on the market that is commonly used for roofing, including steel, aluminum, and copper. Some combinations make them suitable for different roof projects.

4. Automation: Most modern Crimping Curving Machines have a faster and more efficient automated custom production process that upgrades efficiency.

5. Flexibility: The machines of our company can come fitted with adjustable settings to suit different widths of the panels and their bending requirements, allowing them to bend into complex geometric shapes and being able to create varied shapes to complement.

6. Safe operation: Our Crimp bending machine has built-in safety mechanisms that enable it to prevent accidents during its operation.

7. Speed & Efficiency: Installation becomes speedy with the use of a Crimping Curving Machine, efficient as well as cost-effective.

8. Quality assurance: YOUDELI company focuses on Roof Roll Forming. For the Custom Crimp Bending Machine, we have a strict production quality control process and have passed the test. We also have a warranty for our equipment for more than one year.

About Youdeli Company

Youdeli Roll Forming Equipment Factory specializes in offering high-quality and customized roof roll forming equipment. We are located in Xiamen, an advantageous position for the industrial equipment manufacturing industry. Coupling years of industry experience with a spirit of innovation, we present customers with first-class building metal roof and wall solutions.

Professional Customization: We know that every customer’s needs are unique. So, we give each project a professional attitude, fully understand the requirements of customers, and develop roll forming equipment according to their specific needs. From panel size to curve requirements, our equipment is designed to perfectly match various roof and wall applications.

Technical Innovation: Youdeli has a team highly passionate about technical innovation and engineering design. We continuously invest in research and development and use the most advanced technology and materials to make sure that our equipment remains at the forefront of the industry. Our roll forming machines are not only efficient and precise, but they also offer outstanding reliability for complex tasks.

Quality Comes First: We hold the view that quality is the lifeline of an enterprise. For this reason, we exercise strict control over every link in the production process, right from raw material selection up to equipment assembly and testing. Through this method, we ensure the highest standard for every piece of equipment delivered to our customers, which will stand the test of time and use.

Customer Satisfaction: Youdeli maintains customer satisfaction as the primary goal. We establish long-term relationships with our customers by delivering exceptional products and services. If you are seeking personalization or have a technical question, we will provide you with all the necessary support.

If you want a trustworthy source of roll forming machines, Youdeli wants to be your friend. Please feel free to reach out to us and let’s talk about how we can suit your needs, better your productivity, and make sure your project goes well.

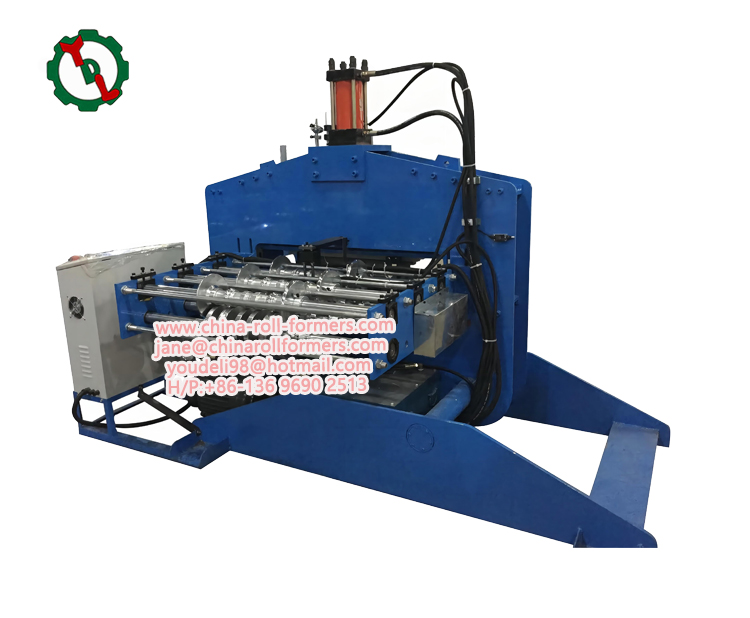

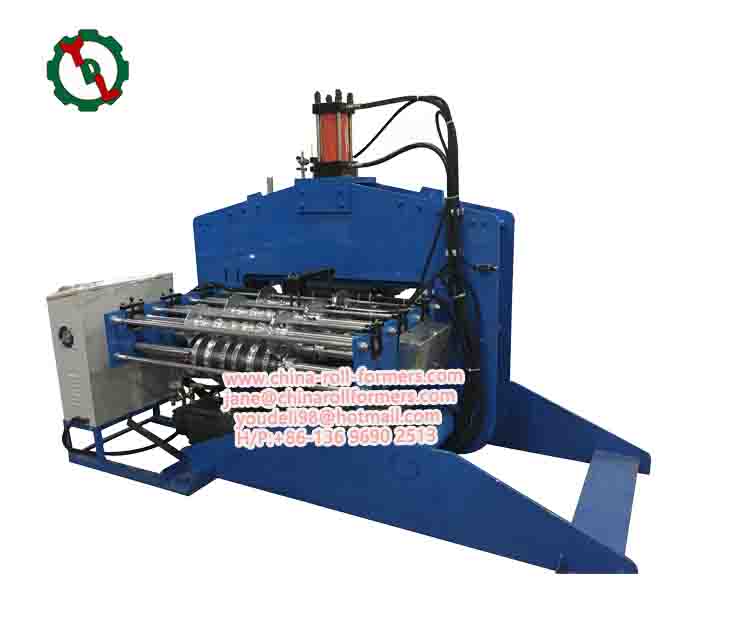

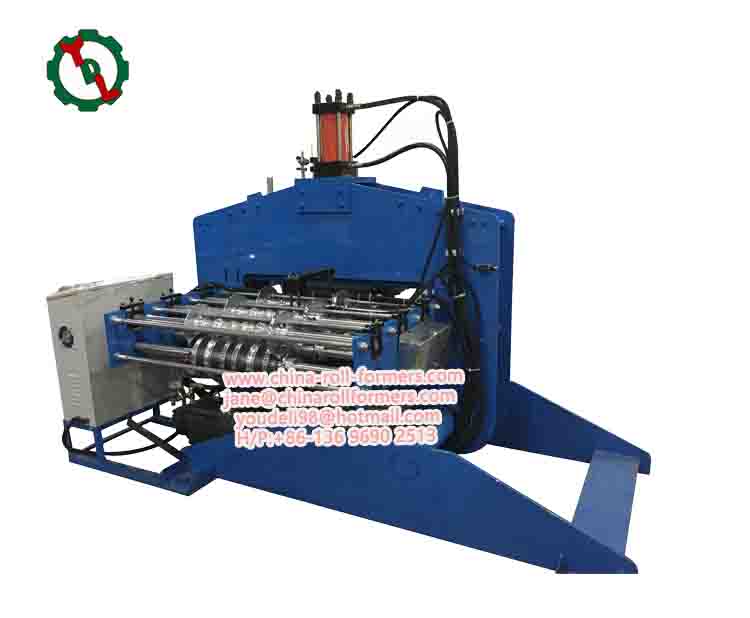

Product View of Crimping Curving Machine

Product Parameter

| Main Technical Parameter | |

|---|---|

| Type | YX65-300-400-425-500 |

| Roofing Width | 300mm, 400mm, 425mm, 500mm |

| Min. Curved Radius | Convex R. 1m |

| Material Thickness | Al: 0.7-1.2mm, Steel: 0.6-1.0mm |