Introduction

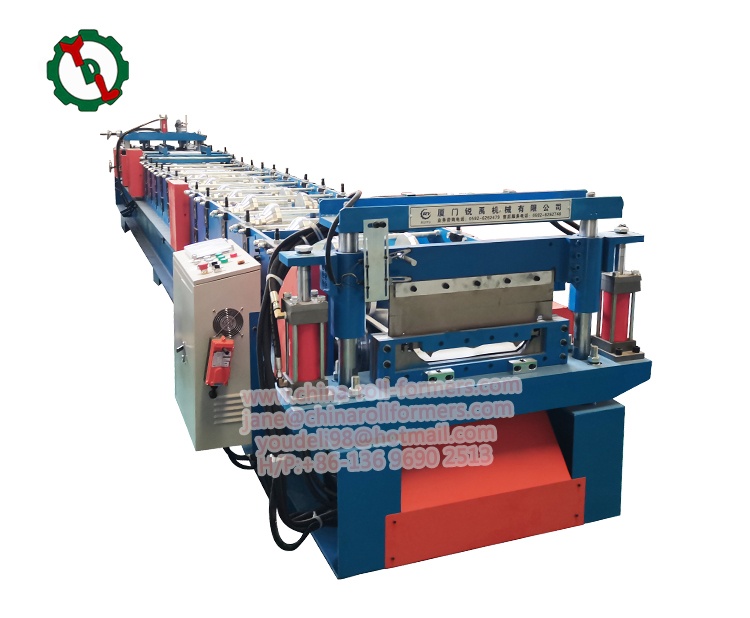

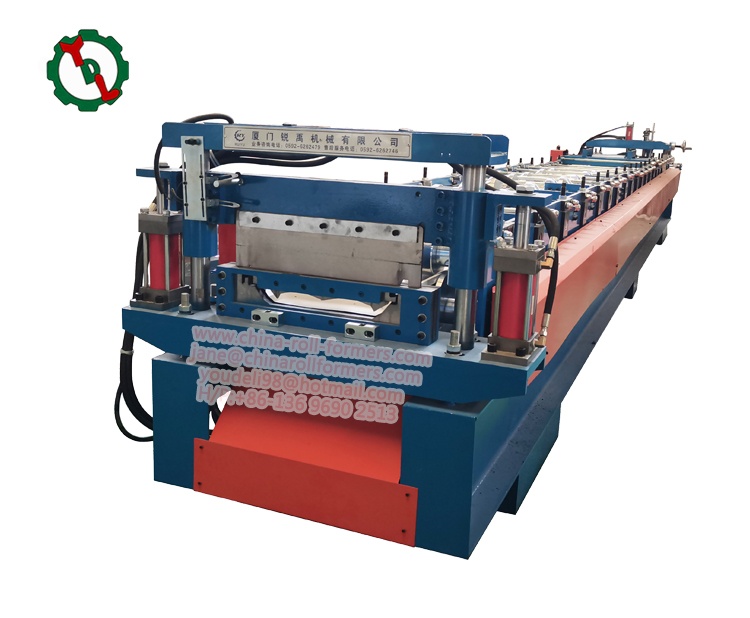

The Standing Seam Profiling Machine is a sophisticated piece of equipment designed for the seamless creation of standing seam metal roofing panels. This machine is meticulously engineered to deliver precise profiling, ensuring uniformity and consistency in panel dimensions. It is an indispensable tool for metal roofing manufacturers and contractors seeking to produce high-quality standing seam panels for residential, commercial, and industrial applications.

Applications of Standing Seam Profiling Machine

The Standing Seam Profiling Machine has a wide range of applications and is mainly used for the production of large metal roof panels, which can be used in a variety of occasions, including:

- Residential Construction: The Standing Seam Profiling Machine can be used to fabricate metal roofs for residential buildings, providing homes with high-quality roof coverings that ensure homes remain safe and dry in all weather conditions.

- Commercial Buildings: Commercial buildings usually require a larger area of roof coverage, and the Standing Seam Profiling Machine can quickly produce large quantities of panels to meet the needs of commercial projects.

- Industrial Facilities: Industrial facilities often require a solid metal roof to protect equipment and inventory. These machines produce durable roofing panels suitable for a variety of industrial applications.

The Standing Seam Profiling Machine works by joining sheets of metal together to create a metal roof covering with standing seams. These standing seams sit above the metal surface for excellent water resistance and durability.

The forming process of standing seam roof sheet metal is achieved by using a specialized machine known as a standing seam former. These machines play a vital role in the production of metal roofing panels, ensuring precise dimensions and the interlocking design required for a weatherproof seal.

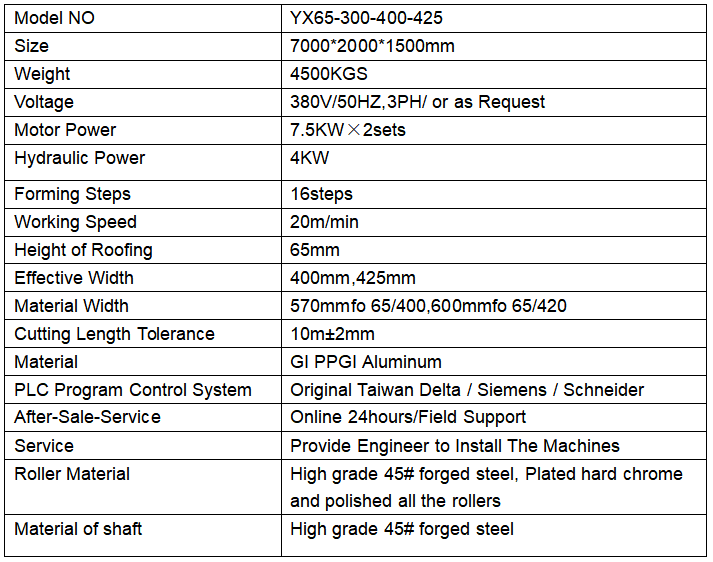

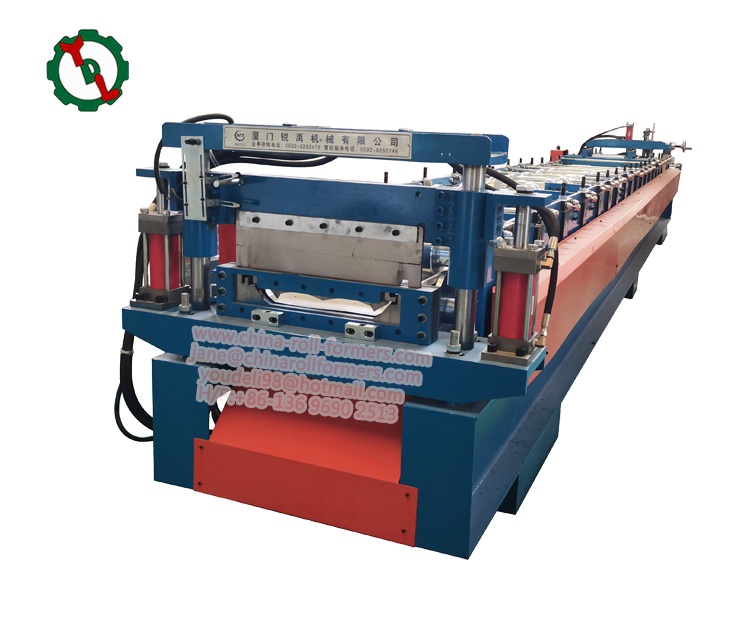

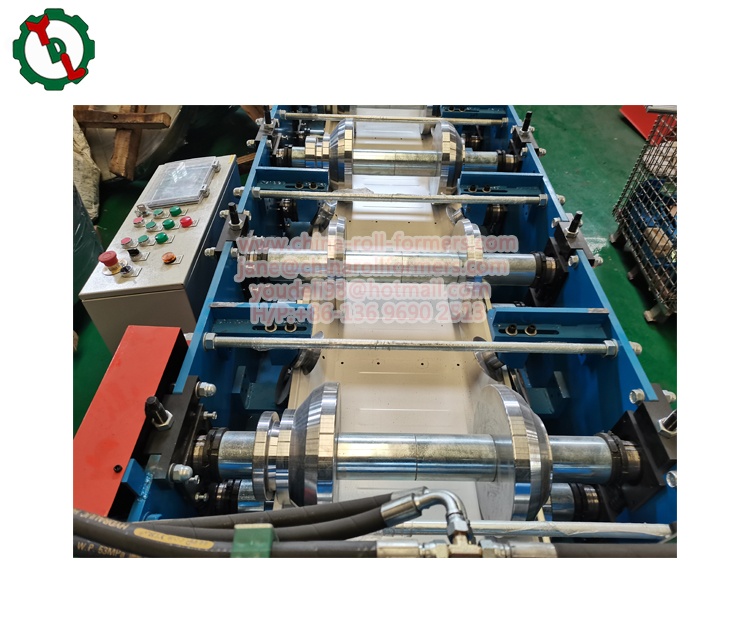

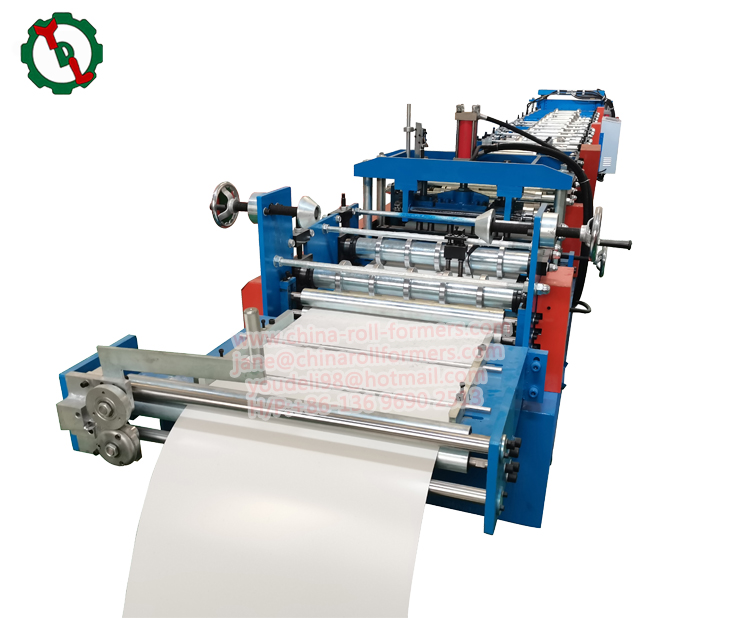

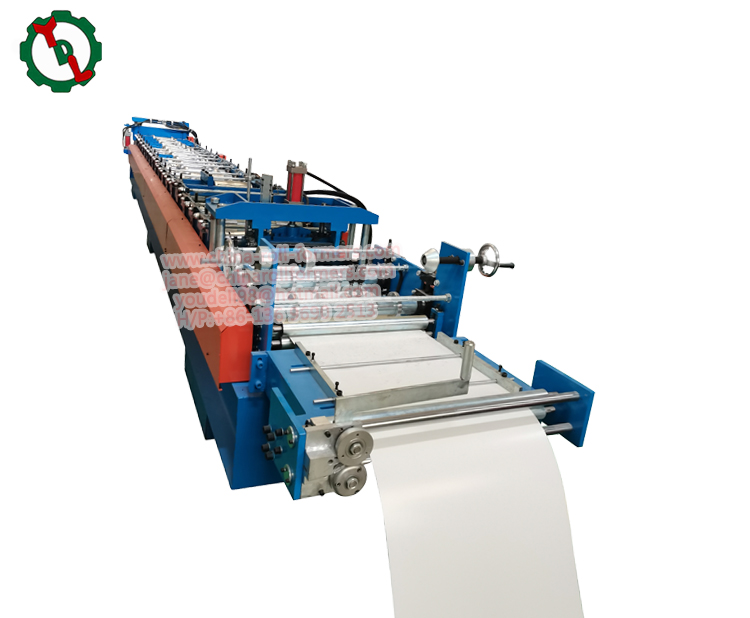

The Standing Seam Profiling Machine consists of several components, including an uncoiler, straightening unit, forming rolls and cutting mechanism.

Here’s how the reshaping process works:

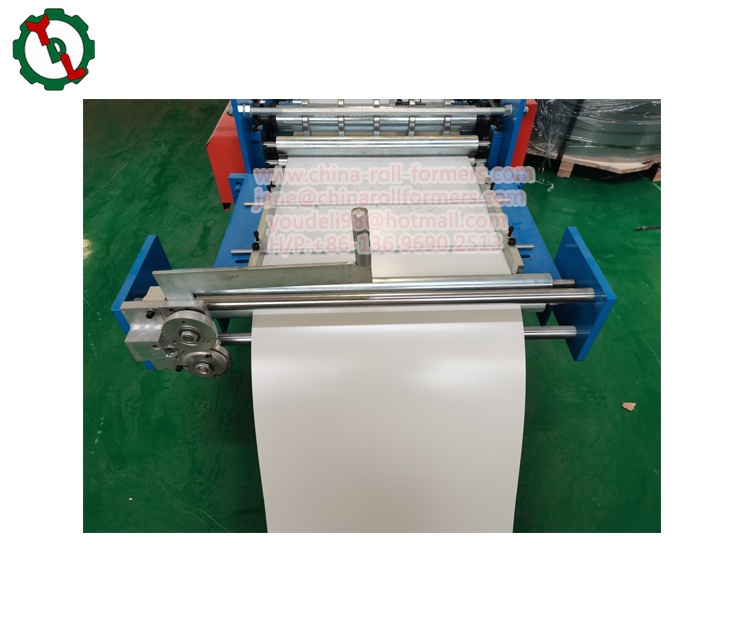

- Uncoiler: The process begins with the uncoiler, which feeds the metal coil into the machine. The web contains the metal raw materials required to form the roofing shingle.

- Straightening unit: When the web is fed into the Standing Seam Profiling Machine, it passes through the straightening unit. This device is used to eliminate any warping or deformation that may occur in the metal during transportation or storage. It ensures the metal is in the correct forming conditions.

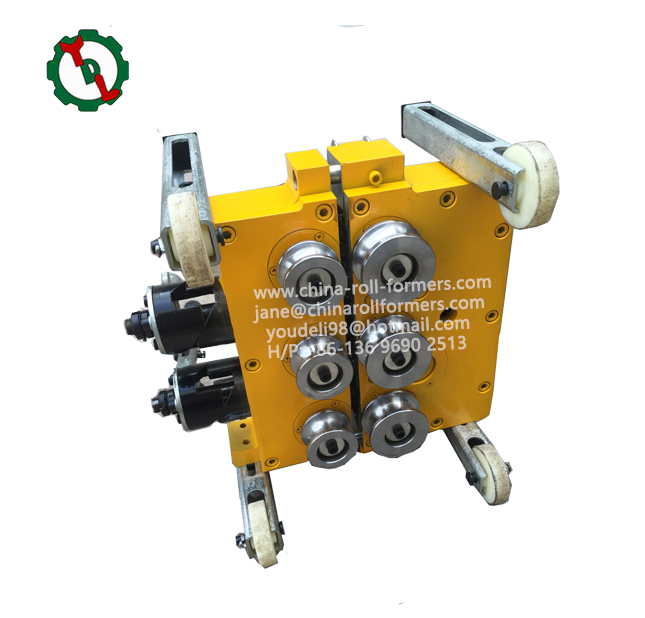

- Forming Rolls: At the heart of the process is a series of forming rolls. These rollers gradually mold the metal into the desired profile of the shingles. The scroll wheel is adjustable to control the specific profile of the panel. Typically, panels have raised seams that interlock with adjacent panels to form a weather-resistant seal.

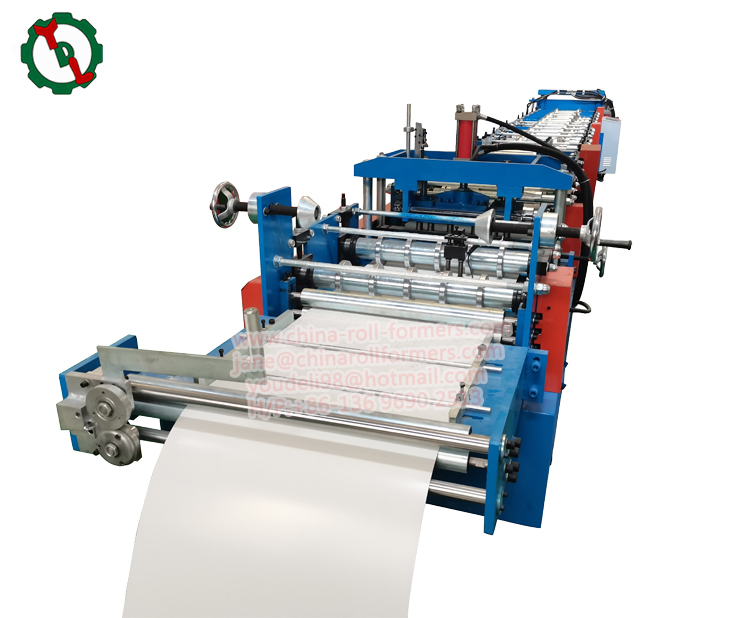

- Cutting mechanism: After the metal is accurately shaped, it passes through the cutting mechanism. The mechanism trims the panel to the correct length, ensuring it conforms to the required specifications.

- Final stacking: Once the panels are cut to the correct length, they are stacked and ready to be shipped to the construction site where they will be installed.

The Standing Seam Profiling Machine is an essential tool for the production of standing seam roofing panels. Its precision, efficiency, and ability to meet specific project requirements make it an essential part of modern roofing fabrication. With the growing popularity of standing seam roofs, the use of Standing Seam Profiling Machines has become more widespread. In youdeli, we focus on providing high-quality, high-precision roll forming equipment, please contact us directly if you have any needs.

Using a standing seam Profiling machine has several advantages:

- Increased Productivity: Our machines are able to quickly produce large volumes of metal panels, thereby speeding up project schedules.

- Manufacturing Speed and Accuracy: Standing seam profiling machines use precise rollers and die to ensure a high degree of accuracy and consistency in the production of metal panels.

- Finished Product Consistency: Due to the automated manufacturing process, the metal panels produced are of a consistently high quality, free from human error.

- Capability to Produce Panels of Different Lengths: These machines can manufacture metal panels of different lengths as required to suit various project needs.

- Reduced Costs: Automated manufacturing processes reduce labor costs while minimizing scrap and reducing production costs.

The Standing Seam Profiling Machine has transformed the way metal roof and wall coverings are manufactured, improving productivity, quality and cost-effectiveness. Whether it’s a residential, commercial or industrial project, these machines provide reliable solutions for the construction industry.

Functions and Operation

The Standing Seam Profiling Machine operates by feeding a metal coil through a series of rollers and dies that gradually shape the metal into the desired standing seam profile. The machine’s adjustable components allow for precise customization of panel dimensions and profiles, ensuring a perfect fit for each project.

Our Standing Seam Roofing Panel Machine Metal Tile Machine is a top-of-the-line solution for producing high-quality metal roofing tiles with ease and precision. Designed for both residential and commercial applications, our machine is perfectly suited for producing a wide range of roofing products including standing seam roofing panels, metal tiles, and more.

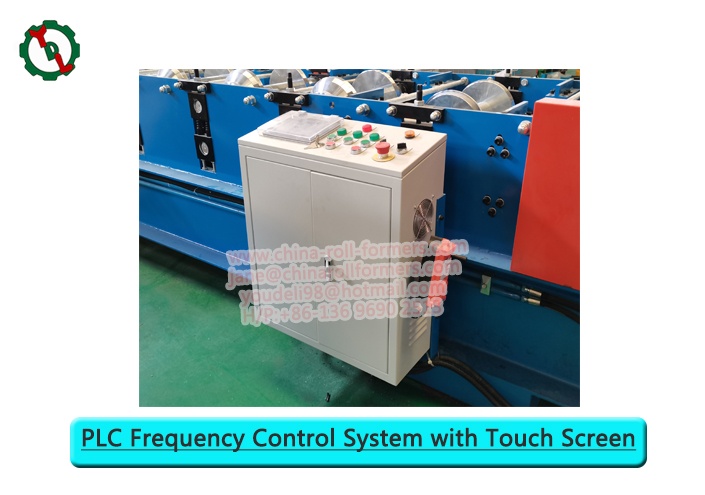

Our machine features advanced technology such as PLC control, touch screen operation, and fully automated production processes, making it easy to operate and ensuring consistent output every time. This means that you can be sure that your roofing products will meet the high standards of quality and durability that your customers demand.

With its modular design, our Standing Seam Roofing Panel Machine Metal Tile Machine is easy to install, maintain, and repair. This means that downtime is minimized while productivity is maximized, giving you a competitive edge in the marketplace.

In addition, our machine is fully customizable to meet your specific needs and requirements. Whether you need to produce a specific type of roofing material, or need to adjust the machine to fit within the limited space of your manufacturing facility, we can work with you to design a solution that meets your needs.

So if you want to produce high-quality metal roofing tiles quickly, efficiently, and accurately, contact us today to learn more about our Standing Seam Roofing Panel Machine Metal Tile Machine. Our team of experts will be happy to answer any questions you have and help you choose the best solution for your business needs.

Accessories

(1) 3MT Hydraulic uncoiler;

(2) Hydraulic System;

(3) PLC Program Control System;

(4) Hydraulic Forming/Post Cutting Device;

(5) Tools;

(6) Operation Manual.

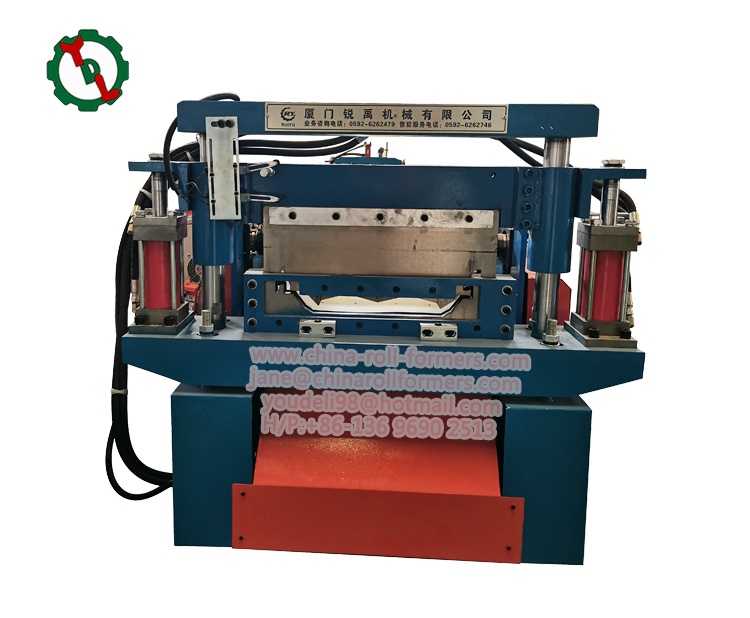

Product Parameters