| Purchase Qty: | 1 Set |

| Port: | Xiamen China |

| Payment Terms: | L/C, T/T |

| Fob: | Inquiry Price |

| Certification: | CE, ISO |

| Condition: | New |

| Customized: | Customized |

| Automatic Grade: | Automatic |

| Transmission: | Motor and Chain For Driving |

| Means of transport: | By sea as full container |

| Packing: | Standard for export |

| Delivery time: | 60 days |

1

Company Profile

2

Products Parameters

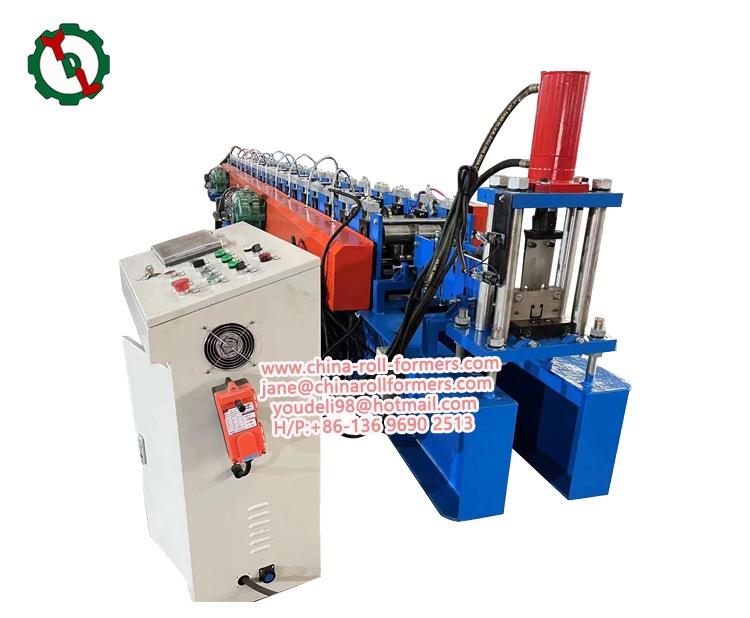

| Model NO. | YX48-500 |

| Size | 9210*1415*1215mm |

| Weight | 6000KGS |

| Voltage | 380V/50HZ/3PH |

| Forming Steps | 18steps |

| Working Speed | 0-18m/min |

| Height of Roof | 48mm |

| Effective Cover Width | 500mm |

| Feeding Material Width | 600mm |

| Forming Steel Thickness | 0.40-0.80mm |

| Tolerance for Cutting | ±2mm |

| Tolerance for Forming Roofing Width | ±3mm |

| Material | GI, PPGI,PPGL, Aluminum, Stainless Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines |

| Material of shaft | High grade 45# forged steel |

3

Products Description

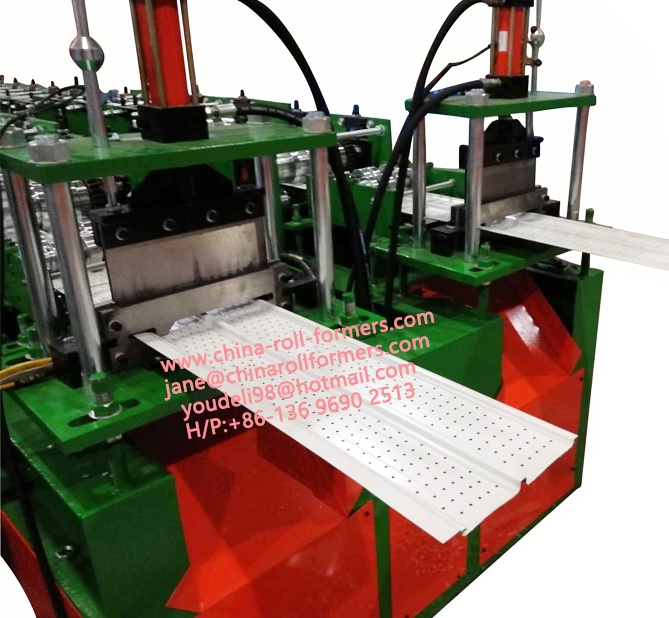

Roller material: 45# steel with machining—Fine Machining— Polishing—Plated Hard Chrome—Polishing;

1、Equipment overview

Through a series of molds and processes, metal coils are processed into roof panels with vertical seam structure. This kind of roof board has excellent waterproof performance and beautiful appearance, and is widely used in the roof of stadiums, exhibition halls, large factories and other buildings.

2、Equipment composition

Standing Seam Roofing Roll Forming Machine is mainly composed of the following parts:

- Unwinding device: used to place the metal coil to be processed.

- Molding mold: Through the pressing and molding of the mold, the metal coil is processed into a seam roof panel.

- Shear device: used to cut the fixed length of the formed roof panel.

- Control system: used to control the operation and parameter setting of equipment to achieve automated production.

What metal materials is this device mainly suitable for

1、color steel plate

Color steel plate is one of the commonly used materials in standing seam roofing roll forming machine. It has good corrosion resistance, weather resistance and decorative, and can meet the aesthetic and practical needs of different buildings. After the processing of the color steel plate by the forming machine, the roof plate with the standing seam structure can be formed for the roof of the stadium, exhibition hall and other buildings.

2、aluminum magnesium manganese alloy

Aluminum magnesium manganese alloy is a lightweight, high-strength metal material with excellent corrosion and weather resistance. It is widely used in the construction field, especially in the manufacture of roofing panels. standing seam roofing roll forming machine can process aluminum magnesium manganese alloy coil to produce metal roof sheet with standing seam structure. This kind of roof board is not only beautiful, but also has good waterproof performance and durability.

3、Stainless steel

Stainless steel is a kind of corrosion resistant, high temperature resistant metal material, also suitable for standing seam roofing roll forming machine processing. Stainless steel roof panel has the characteristics of high strength, not easy deformation and good weather resistance, which can meet the requirements of some special buildings for material properties. However, due to the relatively high price of stainless steel, cost-effectiveness needs to be considered comprehensively when used.

4、galvanized steel plate

Galvanized steel plate is a kind of galvanized steel plate, which has good anti-rust properties. It is suitable for some construction fields with high requirements for rust prevention. standing seam roofing roll forming machine can process galvanized steel sheet coil to produce galvanized roof sheet with standing seam structure. This kind of roof board not only has anti-rust performance, but also has good waterproof performance and durability.

5、Other metal materials

In addition to the above common metal materials, the standing seam roofing roll forming machine can also process other metal materials, such as aluminum alloy, copper alloy, etc. These materials have their own unique properties and characteristics and can be selected according to customer needs. It has good corrosion resistance, weather resistance and decorative, and can meet the aesthetic and practical needs of different buildings. After the processing of the color steel plate by the forming machine, the roof plate with the vertical seam structure can be formed for the roof of the stadium, exhibition hall and other buildings.

4

Our Certificate

Five characteristics of steel:

1, the common “several” word purlin structure, effectively deal with the greenhouse temperature difference formed by the drip dew phenomenon, can effectively deal with the greenhouse in winter dew question.

2, hot dip galvanized steel plate material, good corrosion resistance, longer life, normal service life of not less than 15 years.

3, the appearance is beautiful and modern, the overall structural strength is greater, and the bearing capacity can be far greater than the previous steel pipe structure.

4, all the greenhouse skeleton selection of stereotyped equipment production, convenient device, no solder joints, time will not rust.

5, 10 meters within the span of the skeleton center without pillar, greatly increasing the farming area, saving labor, increasing efficiency.

Choose our strengths

- Experience: We have 15 years of industry experience and expertise to provide you with high quality services.

- Efficient production capacity: YOUDELlhas advanced production equipment and perfect production process. We adopt modern production management methods to ensure that every production link is optimized, thereby improving production efficiency and quality.

- Innovative thinking: We have innovative thinking and advanced scientific and technological means to provide customers with better solutions.

- Professional team: YOUDELlhas a professional research and development team dedicated to the development of efficient, reliable and intelligent equipment. We use the most advanced technology and processes,We have a professional team that can provide you with a full range of services and support.

- Quality service: YOUDELlcompany always adhere to the customer-centric service concept. We provide a full range of pre-sale, sale, after-sales services to ensure that customers in the purchase and use of products in the process of timely help and support.

- Reasonable prices: We offer reasonable prices and fees to make your investment worthwhile.

- Integrity management: We adhere to the concept of integrity management, and can establish long-term stable cooperative relations with customers.

- Good brand image: YOUDELlhas a good brand image and reputation in the field of roofing machinery and related equipment. We pay attention to product quality and service, won the trust and recognition of customers, and set up an excellent image in the market.

5

Cargo Loading

6

Why Choose Us?

- Upon request, we can design and build any kind of roll forming machine.

- This is a very dependable piece of machinery. We have more than 15years of experience.

- This kind of equipment has the best quality and price. It is easy to use and provides precise measurement.Depending on the requirements of the clients, we can create special devices.

- 4.We may provide technical support, production, installation, debugging, and maintenance services to all customers.5.

- Our product has a strong reputation and has been exported to many places due to its high quality and competitive cost.

7

Sample Chamber

FAQ

01.How can I pick the best machine for me?

1. A machine doesn’t only show a few images to demonstrate its capabilities

2. A machine ought to have images and videos of a comprehensive production and assemblysystem. Making sure a company has a thorough after-sales service system is essential whenselecting one with a factory.

02.How can we ensure quality, then?

Before mass manufacturing, there is always a pre-production sample; before shipment, there isalways a final inspection.

03.What products do you offer for sale?

Roof tile Roll Forming Equipment, Wall Roll Former, Tile Forming Equipment, and C Z-PurlinForming Equipment.

04.Do you offer post-purchase support?

With 15 years of production expertise, the strength to ensure, product quality is paramount andservice is the biggest after-sales benefit.

05.How do I request a quote?

1. Please provide me with the dimension drawing and thickness; it is crucial.

2. Please specify in advance if you have any requirements for manufacturing speed, power.voltage, or brand.

3. lf you don’t have your own outline drawing, we can suggest various models based on what istypical in your area.