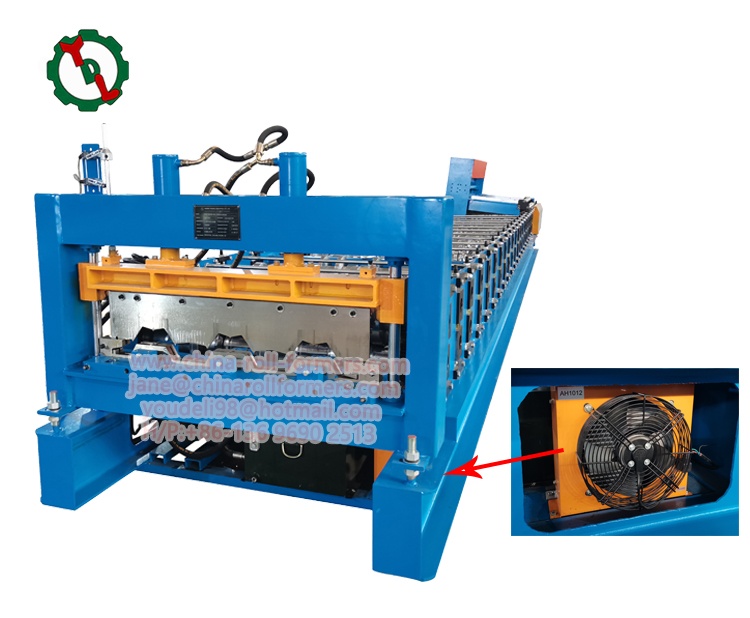

Steel Floor Decking Roll Forming Machine

Products Description

Purchase Qty. 1 Set

Port: Xiamen China

Payment Terms: L/C, T/T

Certification: CE, ISO

Condition: New

Customized: Customized

Automatic Grade: Automatic

Transmission: Motor and Chain For Driving

Means of transport: By sea as full container

Packing: Standard for export

Delivery time: 60 days

| Model NO. | YX50-1000 |

| Size | 11700*2200*1200mm |

| Weight | 12000KGS |

| Voltage | 220V/60HZ,3PH/ or as Request |

| Electric Motor Power | 11KW*2pcs |

| Servo Motor Power | 7.5KW |

| Thickness | 0.8-1.6mm |

| Forming Steps | 24 |

| Forming Speed | 0-18m/min |

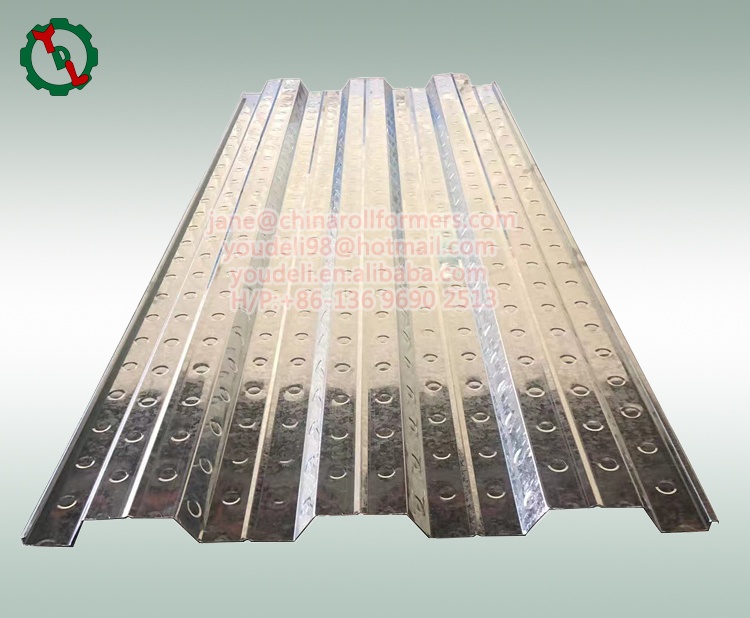

| Rib Height of Decking | 50mm |

| Effective Width | 1000mm |

| Material Width | 1219mm |

| Tolerance for cutting | ±2mm |

| Material | GI PPGI Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines |

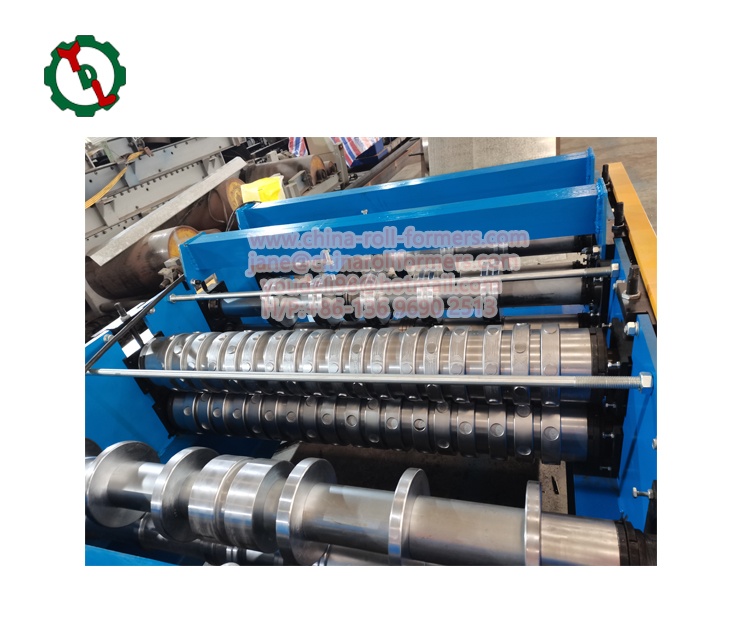

| Roller Material | High grade 45# forged steel, Plated hard chrome

and polished all the rollers |

| Material of shaft | High grade 45# forged steel |

Roller material: high grade NO.45 forged steel with 0.05mm thickness plated with hard chrome on the

surface of the roller.

At 72mm, the active shaft is made of high grade NO.45 carbon wrought steel.

The cutting blade is made of SKD11 mould steel that has been quenched.

THE FACTORY GATE

THE WORKSHOP

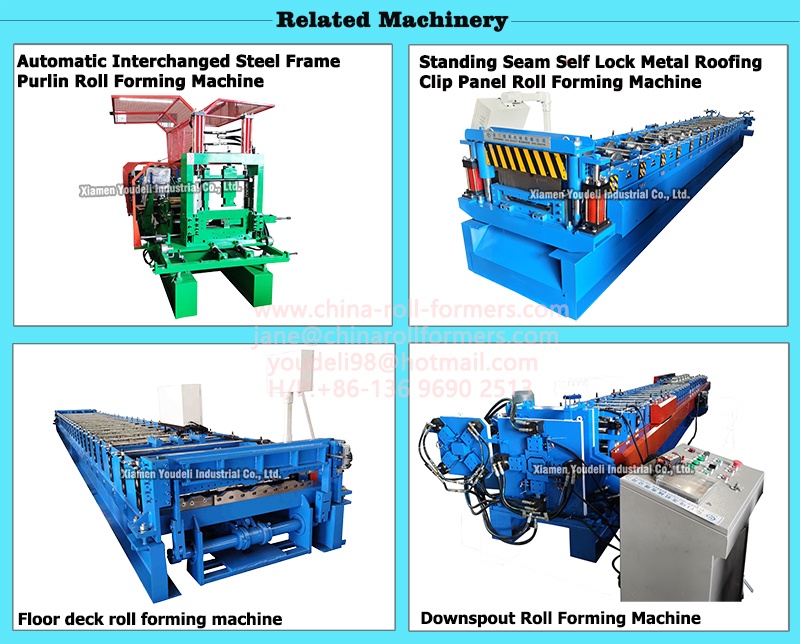

Xiamen YOUDELl lndustrial Co.,Ltd and is professional manufacturer and exporter who are concerned with nearly 20 years of experience for design,development and manufacture of Cold Roll Forming Machines and Roofing System Accessories,Punching Moulds/

Dies and Hardware Products.Such as Standing Seam Roofing Machines, Automatic Smooth/Crimping Roofing Curving Machines,C/Z Purlin Machines,C/U Profile Light Steel Framing Forming Machines,Tile Roofing Machines,Wall/Siding Forming Machines,Floor Decking Machines,

Flattening-Slitting-Cutting Machines,Roofing Seaming Machines,Al Clips,Steel Brackets, Shear Studs and Other Related Products.We are located in nice island City–Xiamen with convenient Transportation access.All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the word. Such as Korea, Philippines, Malaysia ,Singapore, Indonesia,Thailand, India,Turkey,UAE, lran, Lebanon, Sri Lanka, Kazakhstan, Libya, Uganda,Canada, Brazil, Bolivia, Australia,etc.over 30 countries. lf you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.Bearing in mind the service tenet of “Pour your satisfaction with your heart” , YOUDELI is guided by the Enterprise Development Philosophy of “honesty first, honesty and pragmatism” . YOUDELI industrial sincerely welcome friends from all walks of life to visit the company, study, guidance, we look forward to your arrival!

1. Time-Saving

Steel Floor Decking Roll Forming Machine are highly efficient and can produce metal decks in a short amount of time. This

means that you can complete your construction project faster and move on to the next phase of the

project. This can save you a lot of time and money in the long run.

2. Cost-Effective

Steel Floor Decking Roll Forming Machine are cost-effective because they can produce high-quality metal decks at a lower

cost than traditional construction methods. This is because they require less labor and materials, which

can save you a lot of money in the long run.

3. Durable and Strong

Metal decks produced Steel Floor Decking Roll Forming Machine are highly durable and strong. They can withstand

heavy loads and are resistant to fire, water, and other environmental factors. This makes them an ideal

choice for commercial and industrial buildings that require a sturdy and durable floor.

4. Customizable

Steel Floor Decking Roll Forming Machine can produce metal decks in a variety of sizes and shapes. This means that you

can customize your metal deck to fit your specific construction needs. This can help you achieve your

construction goals more efficiently and effectively.

5. Easy to Install

Metal decks produced by Steel Floor Decking Roll Forming Machine are easy to install. They can be quickly and easily

installed on the construction site, which can save you a lot of time and money in the long run.

Types of Floor Decking Machines

(1) 5MT*1250MM Manual Uncoiler;

(2) Main Roll Forming Machine for Web Decking;

(3) Feeding Table;

(4) Hydraulic System( Solenoid Valve Brand: YUKEN );

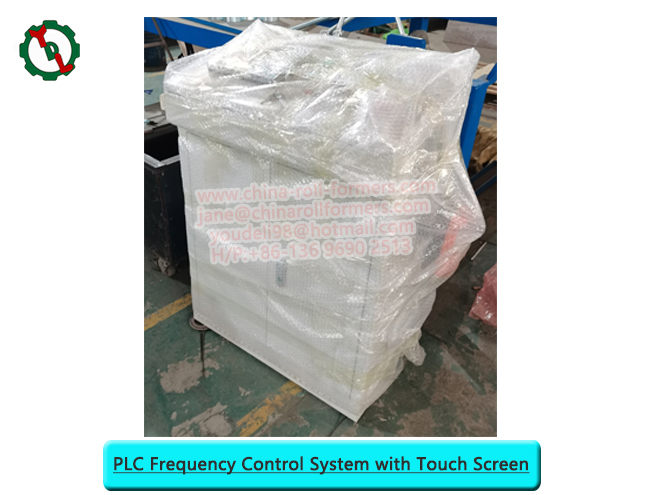

(5) PLC Computer Controlling System with Touch Screen; ( Brand: Delta for Frequency Changer, PLC, Touch

Screen and other parts, Omron for Encoder );

(6) Hydraulic Flat Pre-Cutting Device( Flat Cutter, with encoder for counting length and quantity);

(7) Hydraulic Post Cutting Device( Blade Material: Japan Import SKD11 Steel, Stop Scrap Cutting );

(8) Run Out Tables ( 4pcs );

(9) Tools;

(10) Operation Manual.

1.Strict material selection: stringent installation requirements, meticulous material selection, and a

refusal to cut corners.

2. Simple operation: it’s simple to set up, operate, and utilize.

3. Consistent performance: solid structure, well-developed technology, and a long service life.

4.Stable operation: The application of mature technology in conjunction with the current state of

domestic and international manufacturing.

FAQ

Q1. Do you operate a manufacturing or trade business?

A: We are a recognized manufacturer of machinery for cold metal roll forming.

Q2.How do I visit your factory, please?

A:From the Xiamen North Railway Station or the Xiamen International Airport, we may pick you up and

transport you to our plant.

Q3. Do you offer equipment that is adaptable?

A: Yes, we can design and construct the gadgets in accordance with your requirements. In the design

and manufacture of cold metal roll forming machines, we are specialists.

Q4. Does a machine have a maximum size it can produce?

A: It is not exact since it depends on the machine.

Q5. Was quality control included throughout the manufacturing of the machines?

A:Yes, we have trustworthy teams in charge of quality control, from the selection of raw materials through

the production of machine frames, rollers, shafts, and other parts through installation, adjustment, testing,

and packing.

Q6.Why do you charge more than other businesses, specifically?

A: Since we are convinced that a company’s top goal should be quality, we must take care to process machines

properly at every level, acquire better machine quality, and offer top-notch services to our customers.

Q7.What options are available if the machine malfunctions?

A: The warranty period for our devices is one year. We will courier new replacement parts for any parts that

break down within the guarantee term and replace them within a week. We can negotiate a resolution based

on the actual condition of the equipment if a problem develops after the warranty period has expired. In any

case, we can promise that our technology will be supported for as long as our devices exist.

Q8.Do you provide assistance for post-technology?

A: We are delighted to give advise and, if necessary, have qualified staff available to service equipment abroad.

Q9.Do you employ engineers from other countries?

A: Yes, in addition to sending highly skilled specialists abroad, we can also provide technological training.

10. Can you respond to the machine transport?

A:Yes, kindly confirm with us what your target port or location is. We offer excellent services from a cooperating

shipping company.