The working principle of CZ purlin machine is very simple but efficient. It is a versatile tool for making C- or Z-shaped purlins, which are very important materials in the construction industry and are widely used in various applications such as residential buildings, agricultural buildings, industrial buildings and warehouses.

The working principle of CZ type purlin machine:

- Material feeding: First, the galvanized steel or colored steel strips are fed into the machine. These strips are usually supplied in coil form. These reels are mounted on the uncoiler of the machine and started to run.

- Leveling and punching: The steel strip enters the leveling device to ensure it is straight. Then, through the punching machine, the punching or groove processing is precisely carried out on the steel strip according to the design specifications. The location and size of these holes or slots is determined by the type and specification of purlins required.

- Cutting: After punching, the machine uses a cutting machine to cut off the excess steel strip, leaving only the required length of steel strip. This ensures that purlins are produced to a standard size, reducing waste.

- Forming: The high-speed forming machine is the core of the CZ purlin machine. It consists of a set of forming rollers that gradually bend and form the steel strip into the shape of a C or Z purlin. This process is fully automated and very fast. The machine can produce purlins in various lengths and sizes as required.

The automatic feature of the CZ purlin machine ensures the precision and speed of production, and it is very reliable and durable as it requires less maintenance. In addition, it has a modular structure that can be easily changed and expanded to suit different design requirements. This enables manufacturers to produce a wide variety of purlins in different specifications and sizes to meet the needs of different projects.

An extremely sophisticated piece of machinery called the Automatic Adjustment Z-Type Purlin Forming Machine is used to precisely and quickly produce high-quality Z-type purlins. This machine can easily and quickly adapt its settings to take into account a variety of various materials and specifications thanks to its cutting-edge automatic adjustment capabilities. The machine’s user-friendly interface is one of its primary characteristics. Operators may quickly and simply change the settings as needed thanks to the control panel’s highly intuitive and simple design. This increases the machine’s efficiency while simultaneously lowering operator mistake rates and the likelihood of accidents.

The Automatic Adjustment Z-Type Purlin Forming Machine’s capacity to create purlins with different thicknesses and widths is another benefit. Because of this, it is a great option for factories that need to create a wide range of goods. Steel, aluminum, and other metals are just a few of the materials that the machine is capable of processing. Its great degree of accuracy is one of its main advantages. The purlins are always created precisely and without any faults thanks to the automatic adjustment system. This lessens waste and enhances overall quality assurance.

The Automatic Adjustment Z-Type Purlin Forming Machine is made to be very simple to maintain from a maintenance standpoint. It comes with a thorough user handbook that outlines how to maintain the device operating smoothly and effectively. The machine is also made to be incredibly strong and long-lasting, ensuring that it will offer many years of dependable service. Overall, any industrial organization that needs to swiftly and effectively produce high-quality purlins should consider the Automatic Adjustment Z-Type Purlin Forming Machine. This machine is certain to provide reliable results each and every time because to its cutting-edge automatic adjustment technology and user-friendly interface.

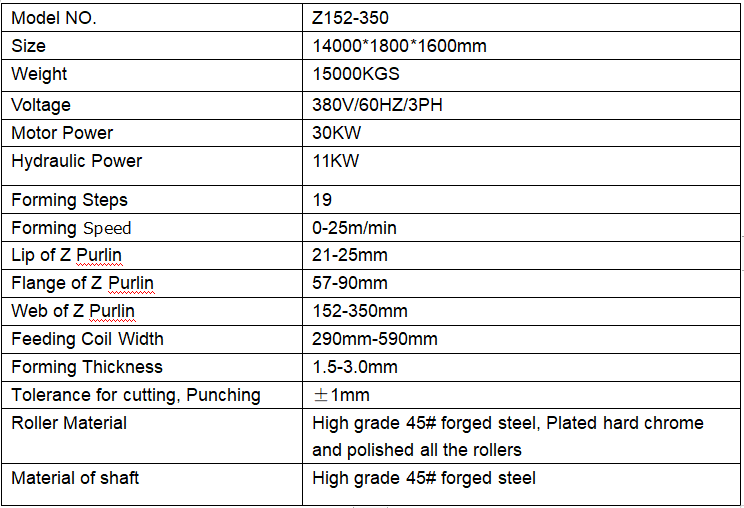

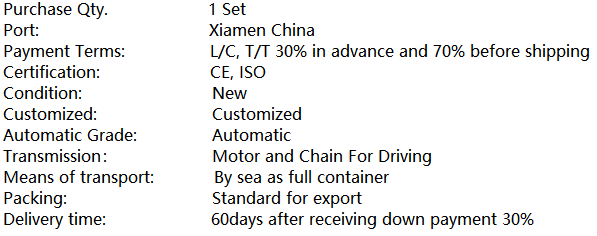

Main Technical Parameter

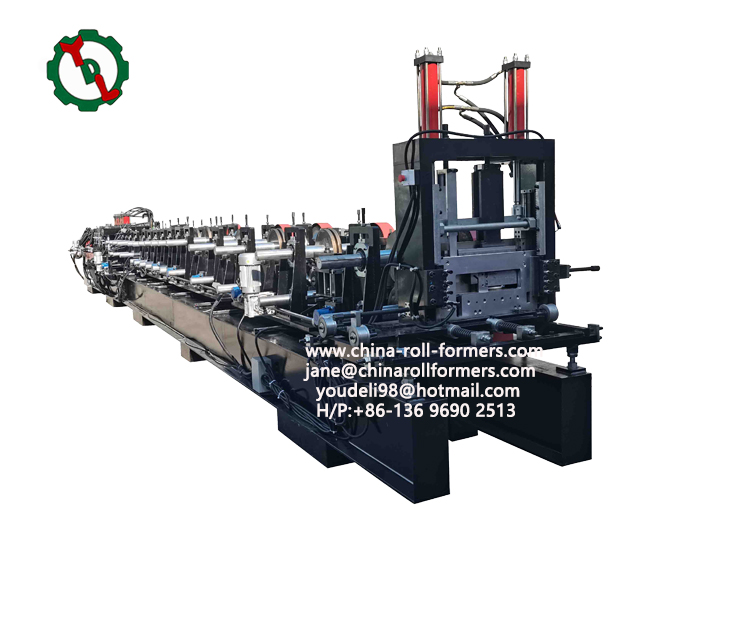

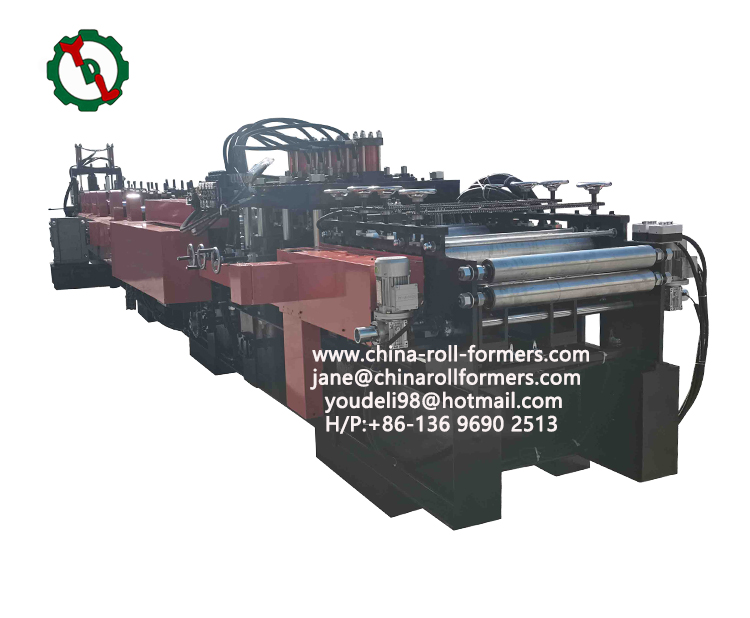

Master Diagram

Accessories

- 5MT*600mm high pressure decoiler

- Hydraulic system of the press (solenoid valve brand: Yuken)

- PLC program control system with laptop, including software to get NC data from Tekla Software for controlling machine production (brand: Schneider PLC and other parts, Omron encoder):

- The hydraulic pre-punching device is equipped with 4 sets of hydraulic cylinders and dies (aperture: 14*28mm, 011mm, 014mm, 018mm):

- hydraulic pre-cutting device;

- Fully automatic Z-shaped purlin forming machine with variable side:

- stereotypes device;

- 152mm-350mm various sizes of hydraulic rear cutting device (material: SKD11 steel, to prevent waste cutting);

run out(2, length: 3M, unpowered); - the tool;

- Operating Manual;

Cargo Loading

FAQ

1. Do you have a direct factory?

We are a reputable producer of cold metal roll forming equipment.

2. What is the best way to travel to your factory?

We can pick you up from Xiamen Gaoqi International Airport or Xiamen North Railway Station at our plant.

3. Is your machine tailor-made or off-the-shelf?

We specialize in the design and production of cold metal roll forming equipment. We can design and build the machine to your specifications.

4. Is the equipment capable of producing numerous specifications?

Yes, it is dependent on your requirements.

5. How do you maintain quality control?

We have a responsible team that will be in charge of cutting down raw materials, processing the machine frame, rollers, shafts, and other quality control parts, heat-treating rollers and shafts, installation, adjustment, testing, and packing, and so on.

6. How come your price is more than the competition’s?

We must underline that we must perform well in every phase of the machine’s processing in order to obtain a higher quality machine and provide good service to our clients, since we believe that every firm must prioritize quality first and foremost.

7. What should be done about the broken machine?

Our unit comes with a one-year guarantee.

If any part fails within the assured time frame, we will replace it within one week of the expedited delivery. If the warranty term ends, you can resolve the counterparty’s complaint in line with the machine’s real circumstances through discussion. In summary, we can guarantee that our technology will be available to assist our machines during their full life cycle.

8. Is there after-sales technical support?

Yes, we are delighted to make some recommendations, and there are abroad skilled and technical individuals who supply machinery services if you require them. 、

9. Are there any engineers in other countries?

Yes, we can give not only highly experienced technicians overseas, but also technical training.

10. How should the transportation be operated?

Please confirm with us your destination location or port, as we work with our shipping provider to provide excellent service.