The Z-shaped purlin roll forming machine is a mechanical equipment specially used for manufacturing Z-shaped purlins, which can easily and quickly produce Z-shaped purlins with precise shapes. Purlins are an important part of building roof structures, often used to support and connect roof covering materials such as metal shingles, shingles or roof panels.

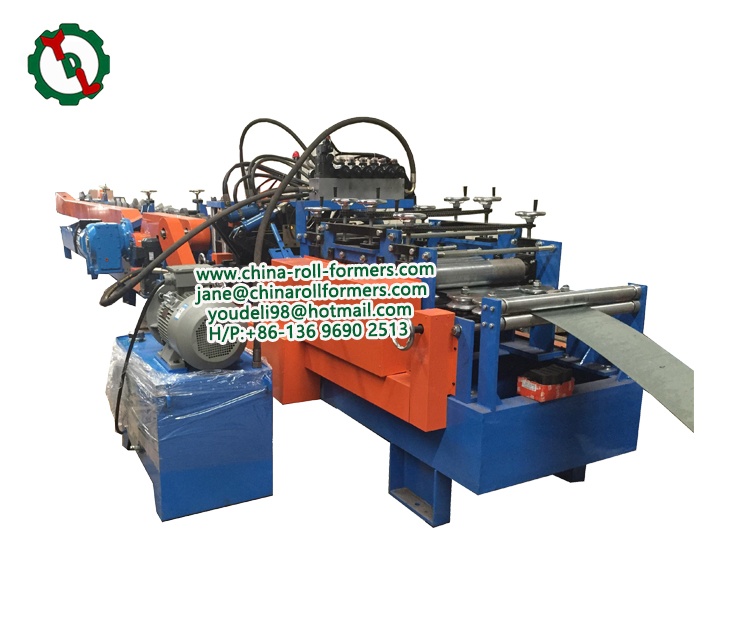

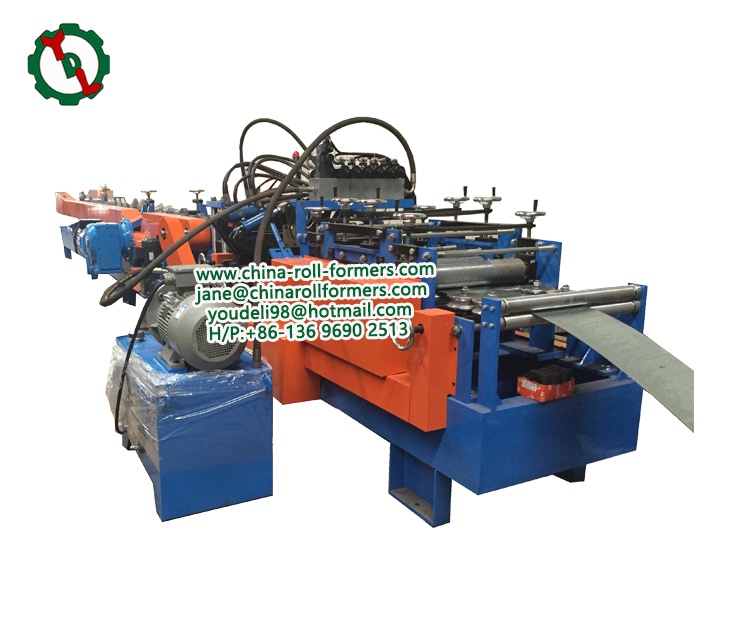

The function of the Z-purlin roll forming machine is to process the metal coil into the desired shape and size of the Z-purlin through a series of rolling and bending operations. In youdeli, our machines usually consist of a set of rollers, cutting devices and control systems, which can be operated automatically or semi-automatically as required, and our machines have automatic adjustment functions that can easily change the size and shape of the purlins as required.

Specification

- Size: 7500*2000*1200mm

- Weight: 6000KGS

- Voltage: 220V/60HZ/3PH

- Hydraulic motor power: 22KW

- Forming steps: 18

- Forming speed: 0-18m/min

- Forming thickness: 1.5-3.0mm

- Commonly used and tested thickness: 1.0-3.0mm (material: galvanized)

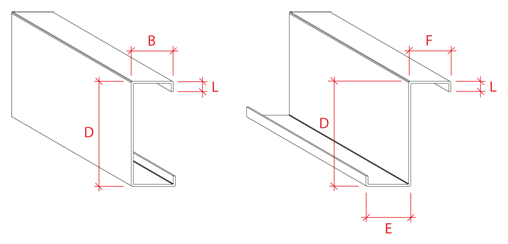

- Z purlin lip: 15mm

- Purlin width: 140mm, 170mm, 250mm

- Cutting length tolerance: ±2mm

- All Roller Material: High Grade No. 45 Forged Steel with Heat Treatment

- Treatment, the surface of the roller is plated with hard chrome;

- Main shaft material: high quality 45# forged steel

- Provide after-sales service: engineers can repair machinery overseas

Features of Automatic Adjustable Z Type Purlin Roller Blind Cold Forming Machine

- Create a wide range of purlin sizes without switching rollers or spacers.

- There is no need to change the cutting tool when the size changes.

- Easy to operate and low maintenance cost

- Unlimited size (any size within the machine range), helps to save material

- Holes can be drilled at any point on the purlin web and flange sides

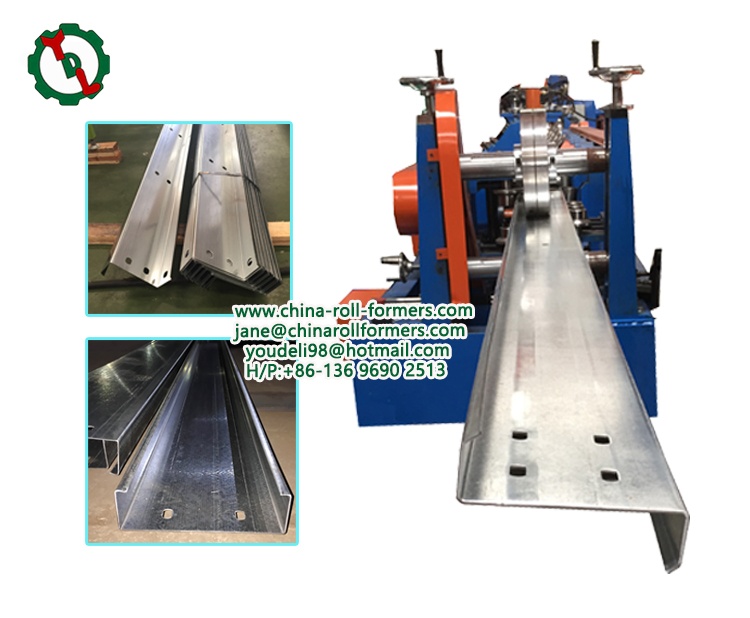

Z-shaped purlin roller blind cold bending forming machine parts

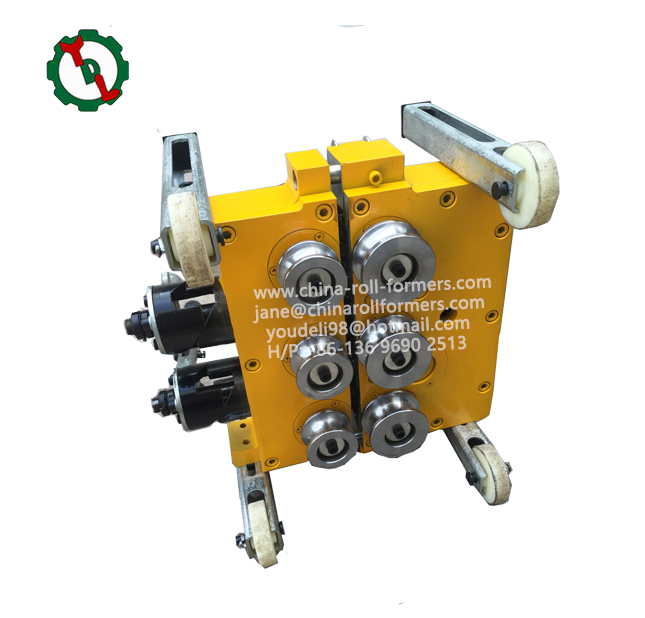

- Punching mechanism of three-cylinder CZ purlin machine (one cylinder for single hole, two cylinders for double hole).

- Interchangeable straight toothed rolls for cold rolled purlins

The rollers are made of high-quality bearing steel GCr15, processed by CNC lathe, and heat treated. Available in blackened or hard chromed finish. - The fuselage adopts material guide rails and is welded by 400# H-shaped steel. Interchangeable cold-rolled purlin machine column cutters do not need to change cutters of different sizes due to the high-quality Cr12 die steel for heat treatment.

- The tool holder is welded by high-quality 30mm steel plate, pre-punching, pre-cutting, stop punching hydraulic range: 0-18Mpa, hydraulic motor: 22KW changed to CZ cold-rolled purlin machine uncoiler: a set of no power, manual control of steel coil Pore Shrinkage and Stopping

- The outlet frame is used for exchanging rectangular cold-rolled purlins. Two non-powered units (3m*2)

Specialized machinery called Z-purlin roll forming machines are used to create Z-shaped purlins for roofing and cladding constructions. In the construction business, where accuracy and precision are vital, these machines are made to generate high-quality and reliable outcomes.

A continuous strip of metal is fed through a number of rollers during the roll forming process, which gradually shapes the metal into the required profile. In order to create the finished product, Z-purlin roll forming machines often involve numerous phases where the metal strip is formed, cut, and stamped. The procedure is computer-controlled, which guarantees that the final product satisfies the required standards.

In the construction of commercial and industrial structures, Z-purlins are frequently employed. They support the building’s roof and walls as structural components, giving the building its stability and strength. Z-purlins are frequently constructed from steel or aluminum, both of which are resilient, lightweight materials that can endure the extreme environmental conditions.

The construction sector has seen a revolution because to the adoption of Z-purlin roll forming machines, which allow for the mass production of items of consistently excellent quality. Builders and architects have more design freedom since these machines can make Z-purlins in a range of diameters and thicknesses. Construction projects can be finished more quickly and efficiently with Z-purlin roll forming equipment, which results in cost savings for the builders and their clients.

In conclusion, Z-purlin roll forming machines are a crucial piece of equipment for the building sector. In order to generate high-quality Z-shaped purlins that are utilized in the construction of commercial and industrial buildings, they provide a quick, effective, and economical method. These machines’ accuracy and precision ensure that the final product satisfies the required criteria, which is essential in the construction sector. The requirement for sophisticated roll forming equipment that can keep up with demand is increasing along with the need for Z-purlins.

Advantages of Manufacturing Z Purlins

- Structural strength: Z-shaped purlins are made of high-strength metal materials and have excellent structural strength, which can effectively support the roof covering material and make it able to withstand the influence of natural factors such as wind and rain.

- Durability: Metal Z-shaped purlins have excellent durability and are able to maintain their shape and performance for a long time without frequent maintenance or replacement.

- Rapid production: The Z-purlin roll forming machine can efficiently produce a large number of Z-purlins, thereby speeding up the progress of construction projects.

- Customization: In our company, we have extensive experience in customizing roll forming machines, our machines can be adjusted and customized according to the needs of specific projects to produce Z-shaped purlins of different sizes and specifications.