Introduction:

In the ever-evolving field of construction, ongoing technological progress transforms the industry, bringing in novel solutions to improve efficiency and precision. A notable innovation in this context is a specialized piece of equipment designed to enhance the process of floor deck installation – the floor deck machine. This exploration takes a comprehensive look at the intricacies of these machines, unraveling their functionalities and highlighting their crucial role in modern construction.

I. What is a Floor Deck Machine?

A floor deck profiles is a sophisticated piece of construction equipment engineered to automate and expedite the installation of floor decks in buildings. Floor decks, commonly made of steel, serve as a foundational component in the construction of floors, providing structural support and a platform for subsequent construction phases. The machine operates through a series of systematic processes, contributing to the efficiency and accuracy of floor deck placement.

II. Key Components and Mechanisms:

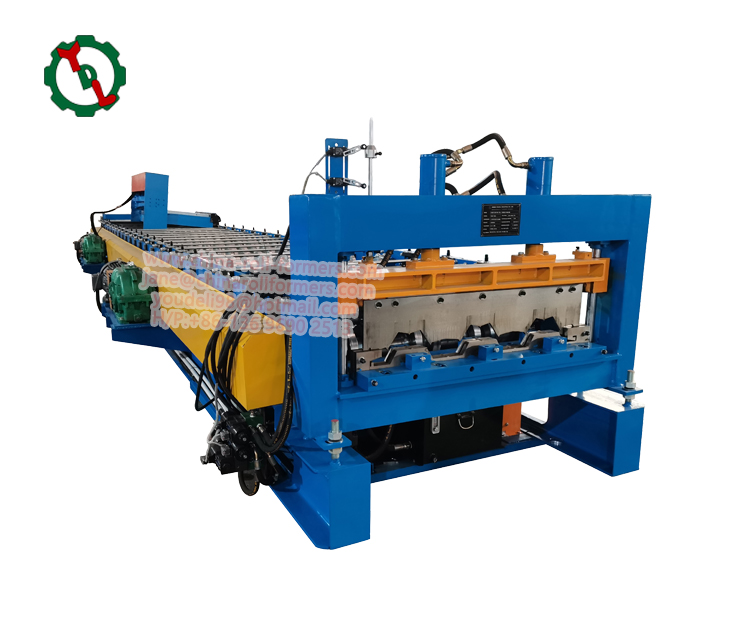

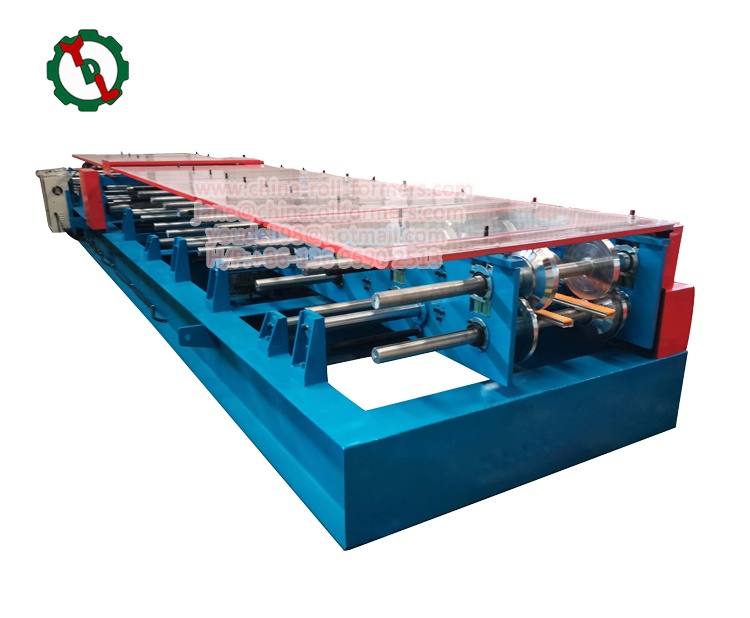

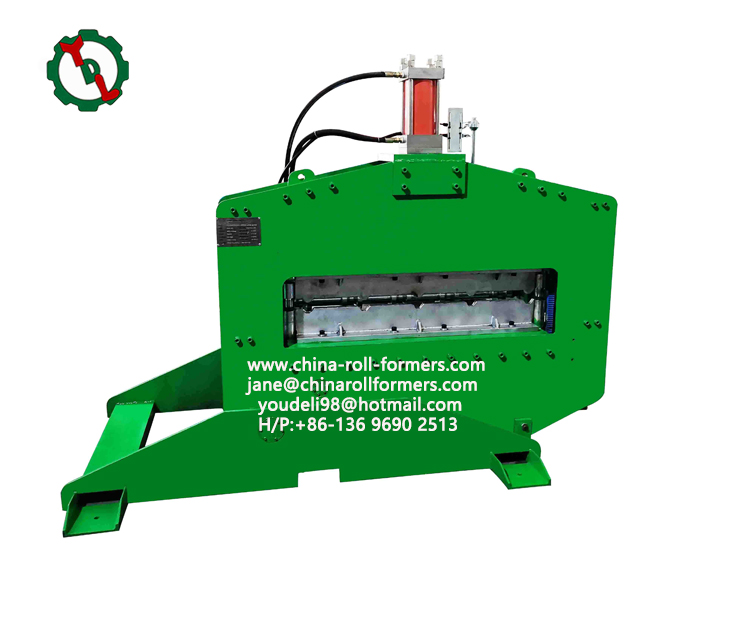

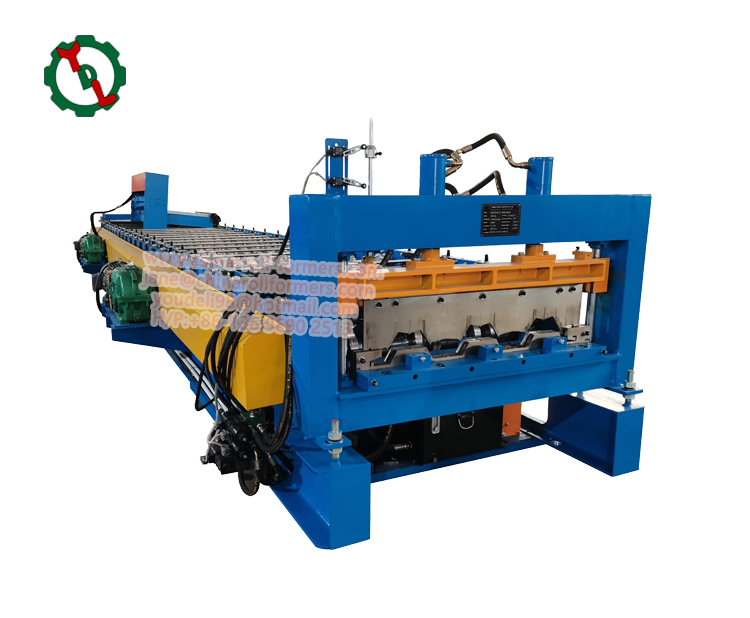

To comprehend how a floor deck machine operates, it’s essential to dissect its key components and understand the intricate mechanisms at play. These machines typically consist of a decoiling system, a roll-forming section, and a cutting unit. The decoiling system unwinds the steel coils, feeding them into the roll-forming section. Here, the steel undergoes shaping and profiling processes, transforming it into the desired floor deck profile. The cutting unit then precisely cuts the floor deck panels to the required lengths, ready for installation.

III. The Roll-Forming Process:

The roll-forming section stands as the heart of a floor deck machine, where raw steel coils undergo a transformative process to achieve the specified floor deck profile. The steel strip passes through a series of carefully calibrated rollers, each imparting a specific bend or contour to the material. This sequential shaping results in the creation of the floor deck profile, characterized by its structural integrity and load-bearing capabilities.

IV. Versatility in Floor Deck Machines:

One notable advantage of these machines is their adaptability to produce various floor deck profiles. Different construction projects may demand specific designs based on load requirements, span lengths, and architectural considerations. They can be configured to accommodate diverse profiles, allowing for versatility in meeting the unique demands of each construction endeavor.

V. Automation and Precision:

The integration of automation significantly enhances precision and operational efficiency. Advanced control systems govern the entire process, ensuring consistent and accurate profiling of the material. Automated adjustments and settings contribute to a seamless workflow, minimizing errors and optimizing the quality of the produced panels.

VI. Speed and Efficiency:

Renowned for their ability to expedite the construction timeline, these automated machines translate to swift production of panels, significantly reducing the time required for installation. This speed not only accelerates project completion but also contributes to cost-effectiveness by minimizing labor and construction overhead.

VII. On-Site Customization:

Flexibility is a hallmark of floor deck machines, allowing on-site customization to meet the specific requirements of a construction project. The ability to adjust parameters such as panel length and profile dimensions ensures that floor deck panels precisely align with the architectural and structural specifications of the building under construction.

VIII. Integration with Construction Workflow:

Floor deck profiless seamlessly integrate into the broader construction workflow, aligning with other processes and equipment. Coordinated efforts between floor deck machines, cranes, and installation crews to ensure a synchronized construction sequence. This integration fosters a cohesive and efficient construction environment, where each component contributes synergistically to project advancement.

IX. Material Efficiency and Sustainability:

The precision offered by floor deck profiles extends beyond speed and accuracy; it also contributes to material efficiency. The controlled profiling process minimizes material waste, optimizing the use of steel coils and reducing environmental impact. This inherent material efficiency aligns with sustainability goals in modern construction practices.

X. Safety Considerations:

Safety is paramount in construction, and floor deck profiles are designed with built-in safety features. Emergency stop mechanisms, protective guards, and comprehensive training for machine operators contribute to a secure working environment. Adherence to safety protocols ensures that the advantages of floor deck machines are realized without compromising the well-being of construction personnel.

XI. Maintenance and Longevity:

To maximize the benefits of floor deck profiles, routine maintenance is essential. Regular inspections, lubrication of moving parts, and prompt replacement of worn components contribute to the longevity and optimal performance of the machine. Well-maintained floor deck profiles uphold reliability, ensuring that they endure the rigors of demanding construction projects.

XII. Application in Different Construction Phases:

Floor deck machines find application in various construction phases beyond initial floor installation. They are integral in projects involving additions, renovations, and expansions, seamlessly adapting to diverse construction requirements. The versatility of floor deck profiles positions them as valuable assets across the entire construction life cycle.

XIII. Customization for Project Requirements:

The adaptability of floor deck profiles plays a crucial role in meeting specific project requirements. Construction projects vary in terms of architectural designs, load-bearing necessities, and floor specifications. Floor deck machines can be customized to produce panels with varying profiles, lengths, and thicknesses, allowing for tailored solutions that align with the unique demands of each construction endeavor.

XIV. Integration with Building Information Modeling (BIM):

In the era of digital construction, floor deck profiles seamlessly integrate with Building Information Modeling (BIM) systems. The precision of BIM data facilitates accurate input into the machine’s control systems, ensuring that the floor deck panels manufactured align precisely with the virtual design. This integration minimizes discrepancies between the digital model and the physical construction, enhancing overall project accuracy.

XV. Quality Control Measures:

Quality control is a paramount consideration in construction, and floor deck machines incorporate measures to ensure the consistent quality of produced panels. Automated inspection systems, inline testing, and real-time monitoring contribute to the identification of defects or deviations during the manufacturing process. This commitment to quality control enhances the reliability and structural integrity of the floor deck panels.

XVI. Maintenance as a Preventive Measure:

Maintenance of floor deck machines is not merely a reactive practice; it serves as a preventive measure to avert potential issues. Regular inspections, lubrication routines, and proactive replacement of components contribute to sustained machine performance. Preventive maintenance ensures that the machine operates reliably, minimizing the risk of downtime during critical construction phases.

XVII. Training for Efficient Operation:

The efficient operation of floor deck profiles hinges on the competence of machine operators. Comprehensive training programs equip operators with the knowledge and skills needed to operate the machine effectively. Training covers aspects such as machine settings, troubleshooting, and safety protocols, empowering operators to maximize the machine’s capabilities and contribute to a smooth construction workflow.

XVIII. Collaborative Workflow Optimization:

Floor deck machines are not standalone entities; they function as integral components within a collaborative construction workflow. Coordination between floor deck machines, crane operations, and construction crews is pivotal for optimizing the overall construction process. This collaborative approach ensures a harmonious sequence of activities, minimizing delays and enhancing project efficiency.

XIX. Evolving Technological Advancements:

As technology continues to advance, floor deck profiles evolve to incorporate new features and capabilities. Emerging technologies such as artificial intelligence, machine learning, and advanced sensors contribute to further automation, precision, and efficiency in floor deck manufacturing. Staying abreast of these technological advancements positions construction projects at the forefront of innovation.

XX. Life Cycle Assessment and Sustainability:

A comprehensive assessment of a floor deck machine’s life cycle contributes to sustainability considerations in construction. Evaluating factors such as energy consumption, material usage, and end-of-life disposal assists in making informed decisions regarding the environmental impact of floor deck profile operations. This life cycle perspective aligns with the industry’s growing emphasis on sustainable construction practices.

In this expansive exploration of floor deck profiles, their diverse advantages come to the forefront. From customization for project requirements to collaborative workflow optimization, these machines represent a paradigm shift in the construction industry. As technology continues to propel construction methodologies into the future, floor deck profiles stand as stalwart contributors to the efficiency, precision, and sustainability of contemporary construction projects.

Conclusion:

In conclusion, floor deck machines epitomize the fusion of technological innovation and construction expertise, revolutionizing the process of floor deck installation. Through precision, automation, and adaptability, these machines offer a host of advantages that contribute to the efficiency, safety, and sustainability of modern construction projects. As the construction industry continues to evolve, floor deck machines stand as a testament to the transformative power of technology in shaping the built environment.