I. Introduction to Standing Seam Profiling Machine

A standing seam profiling machine is a vital tool in the field of roofing, particularly for metal roofing projects. This machine is designed to efficiently and precisely produce standing seam panels, which are commonly used in residential, commercial, and industrial roofing applications. Standing seam roofs are known for their durability, weather resistance, and aesthetic appeal, making them a popular choice among architects, builders, and homeowners.

It plays a crucial role in the roofing industry by enabling the rapid and accurate production of standing seam panels. These machines can handle various types and sizes of metal sheets, allowing for flexibility in design and customization. Additionally, they help reduce labor costs and waste, as they can produce panels with minimal material wastage and require fewer workers to operate.

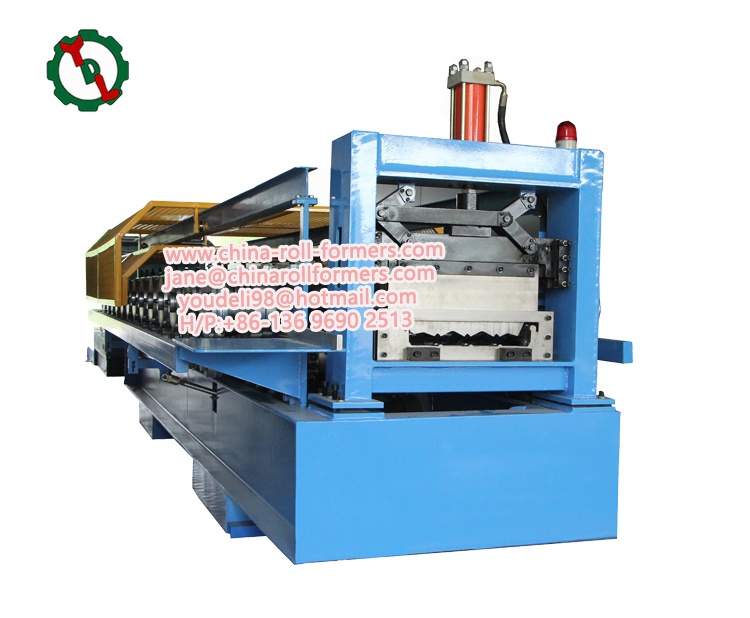

II. Overview of Standing Seam Profiling Machine

A standing seam profiling machine is a specialized equipment used in the construction industry to create standing seam roofs, which are popular for their sleek appearance and durability. This machine plays a crucial role in the roofing process, as it is responsible for forming continuous panels with raised seams, which are characteristic of standing seam roofs.

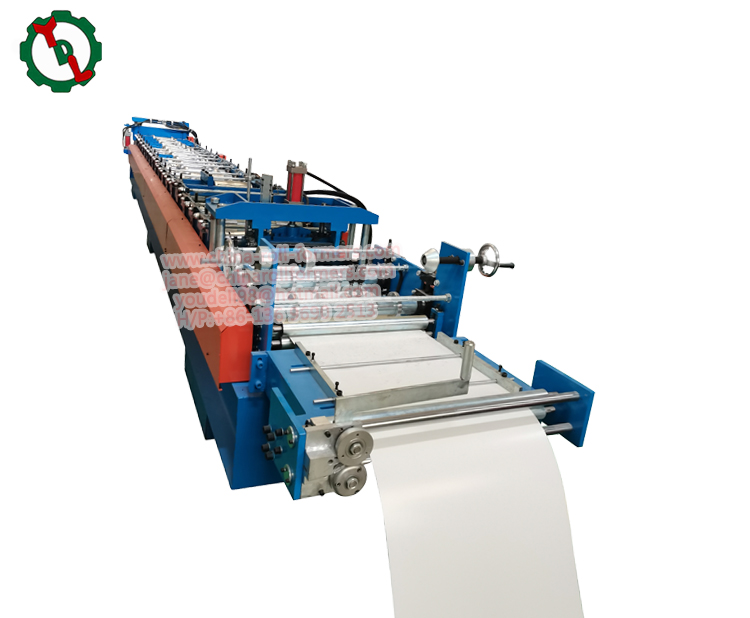

Purpose in Creating Standing Seam Roofs:

Standing seam roofs are known for their clean, modern look and their ability to withstand harsh weather conditions. The standing seam profiling machine is designed to efficiently and accurately fabricate the panels needed for this type of roofing system. It ensures that each panel is formed to the exact specifications required for a seamless and watertight roof.

Formation of Continuous Panels with Raised Seams:

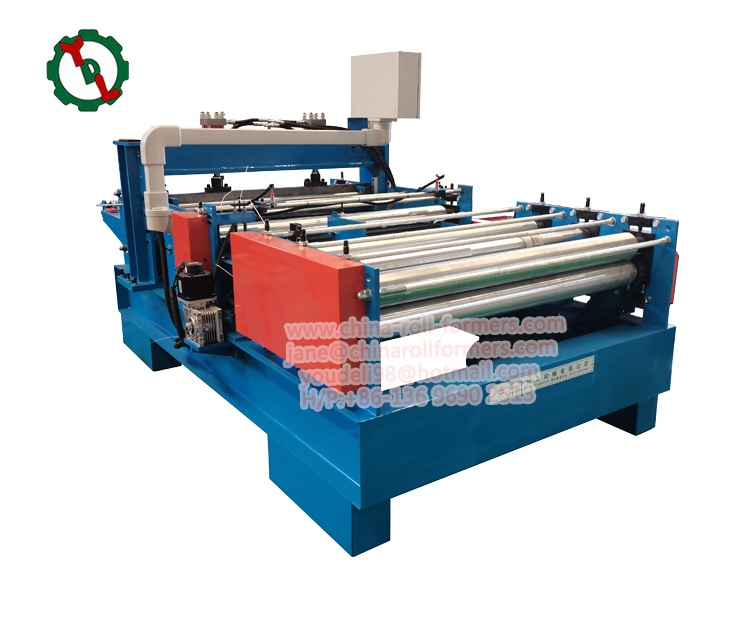

The machine works by feeding metal coils, typically made of steel or aluminum, through a series of rollers and dies. These rollers and dies shape the metal into the desired profile, including the raised seams that are characteristic of standing seam roofs. The process is precise and consistent, resulting in panels that fit together seamlessly when installed on a roof.

Expanded Explanation:

The machine can be adjusted to produce panels of different widths, lengths, and seam heights, allowing for customization based on the specific requirements of a project.

Some machines are capable of on-site fabrication, eliminating the need for pre-fabricated panels and reducing transportation costs and logistical challenges.

Advanced standing seam profiling machines may include features such as computerized controls and automatic feeding systems, further improving efficiency and accuracy.

The durability and weather resistance of standing seam roofs are attributed in part to the precision manufacturing of panels.

III. Advantages of Using a Standing Seam Profiling Machine

Using it offers numerous advantages over traditional roofing methods. These advantages include:

- Efficiency: They are highly efficient, allowing for the rapid production of standing seam panels. This efficiency can significantly reduce labor costs and project timelines compared to hand-formed or pre-fabricated panels.

- Precision: The machine forms panels with precise dimensions, ensuring a tight fit and uniform appearance when installed. This precision helps to create a seamless and watertight roof that is both functional and aesthetically pleasing.

- Customization: They can be adjusted to create panels of various widths, lengths, and seam heights. This customization capability allows for greater design flexibility and the ability to tailor panels to the specific requirements of each project.

- Durability: Standing seam roofs are known for their durability and longevity. The precision manufacturing of panels by the standing seam profiling machine contributes to this durability, ensuring that the roof can withstand harsh weather conditions and maintain its appearance over time.

- Cost-Effectiveness: While the initial investment in a standing seam profiling machine may be significant, the long-term cost savings can be substantial. Reduced labor costs, faster installation times, and minimal material waste all contribute to the cost-effectiveness of using this machine for roofing projects.

- Safety: They are designed with safety in mind, featuring guards and safety mechanisms to protect operators during the manufacturing process. This focus on safety helps to reduce the risk of accidents and injuries on the job site.

IV. Cost Considerations

Cost-effectiveness: Investing in a standing seam profiling machine can initially seem like a significant expense, but it offers substantial long-term cost savings.

- Reduced Labor Costs: The machine automates the process of forming standing seam panels, reducing the need for manual labor. This can result in significant savings over time, especially for large-scale roofing projects.

- Lower Maintenance Costs: Standing seam roofs are known for their durability and require less maintenance compared to traditional roofing materials. This means lower ongoing maintenance costs for property owners.

Return on Investment (ROI): The ROI of a standing seam profiling machine can be substantial for a roofing company.

- Increased Production Capacity: The machine allows for faster production of standing seam panels, enabling the company to take on more projects and increase its revenue stream.

- Reduced Waste: The precision of the machine results in minimal material waste, saving money on raw materials and disposal costs.

- Competitive Advantage: Companies that invest in modern equipment like a standing seam profiling machine can differentiate themselves in the market and attract more customers, further boosting profitability.

V. Environmental Impact

Standing seam roofs offer several environmental benefits, making them a sustainable choice for modern buildings.

- Sustainability: Standing seam roofs contribute to sustainable building practices by increasing energy efficiency. The design of standing seam roofs allows for better insulation, reducing the need for heating and cooling. This can lead to lower energy consumption and reduced carbon emissions over the lifespan of the building. Additionally, standing seam roofs can be integrated with solar panels to further enhance energy efficiency and promote renewable energy use.

- Recyclability: The materials used in standing seam roofs, such as steel or aluminum, are highly recyclable at the end of their lifespan. This means that old standing seam panels can be recycled and used to create new products, reducing the amount of waste sent to landfills. Recycling these materials also helps to conserve natural resources and reduce the environmental impact of metal production.

VI. Conclusion

In conclusion, the standing seam profiling machine offers numerous advantages for roofing projects, making it a valuable investment for roofing contractors and builders. Its efficiency in creating precise and uniform panels reduces installation time and labor costs, while its durability ensures long-lasting performance even in harsh weather conditions. Additionally, the aesthetic appeal of standing seam roofs adds value to any building, making it a popular choice among architects and property owners.

Considering these benefits, roofing professionals are encouraged to explore the use of standing seam profiling machines for their projects to achieve both short-term and long-term advantages. By incorporating this technology into their roofing processes, contractors can improve efficiency, reduce costs, and enhance the overall quality and appearance of their projects, ultimately leading to greater customer satisfaction and business success.