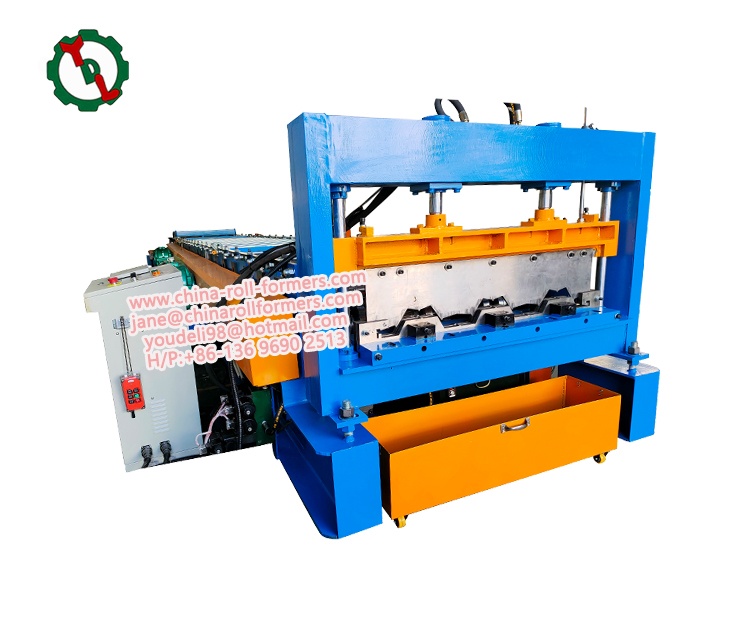

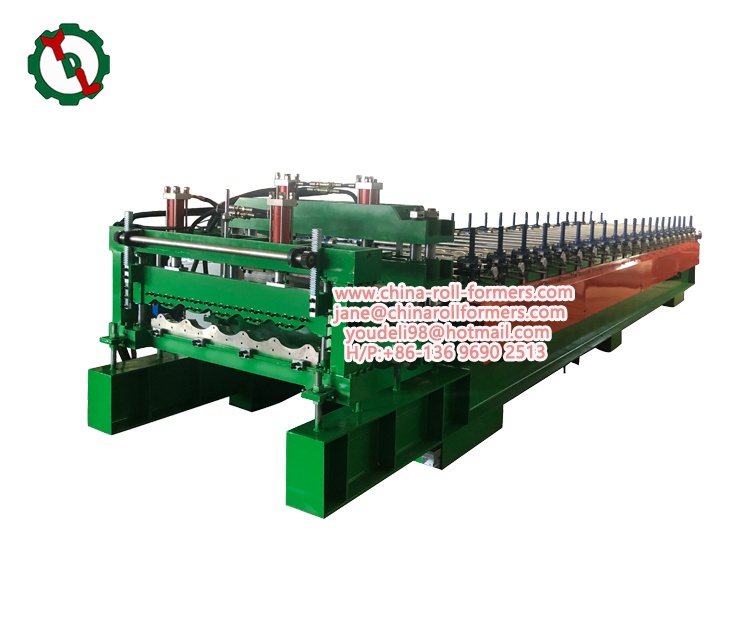

A floor deck machine, also known as a deck roll forming machine, is an essential piece of equipment in the construction industry. It is designed to produce floor deck panels that are widely used in building floors, roofs, and other structural applications. These machines are capable of transforming metal sheets into high-quality deck panels through a continuous roll forming process. The key features of a floor deck machine determine its efficiency, product quality, and suitability for various construction needs. This article explores the essential features of it in detail.

1. Robust Frame Structure

Description

The frame structure of a floor deck machine is crucial for its stability and durability. A robust frame ensures the machine can handle the high pressures and forces exerted during the roll forming process without deforming or vibrating excessively. Typically, the frame is made from high-strength steel to provide the necessary rigidity and support.

Importance

- Stability: A sturdy frame minimizes vibrations, leading to more precise forming and higher quality finished products.

- Durability: High-strength materials ensure the machine can withstand long-term use and heavy workloads, reducing the need for frequent repairs or replacements.

- Safety: A solid frame structure enhances operational safety by maintaining the integrity of the machine under load.

2. High-Quality Rollers

Description

The rollers are the heart of a floor deck machine, responsible for shaping the metal sheets into deck panels. These rollers are typically made from hardened steel or other wear-resistant materials and are precisely machined to specific profiles.

Importance

- Accuracy: High-quality rollers ensure the deck panels are formed with precise dimensions and consistent quality.

- Longevity: Hardened and wear-resistant rollers have a longer service life, reducing downtime and maintenance costs.

- Surface Finish: Well-machined rollers produce a smooth surface finish on the deck panels, which is critical for both aesthetic and functional purposes.

3. Advanced Control System

Description

Modern floor deck machines are equipped with advanced control systems, often featuring Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs). These systems enable precise control over the roll forming process and allow operators to adjust various parameters easily.

Importance

- Precision: PLCs can control the roll forming process with high accuracy, ensuring consistent product quality.

- Ease of Use: HMIs provide a user-friendly interface for operators to monitor and adjust the machine settings, reducing the likelihood of errors.

- Automation: Advanced control systems enable automation, which increases production efficiency and reduces the need for manual intervention.

4. Versatility in Profile Sizes

Description

A versatile floor deck machine can produce deck panels in various profiles and sizes. This flexibility is achieved through adjustable roller setups and interchangeable forming tools.

Importance

- Adaptability: The ability to produce different profiles and sizes makes the machine suitable for a wide range of construction projects.

- Cost-Efficiency: Versatility reduces the need for multiple machines, saving space and investment costs.

- Market Demand: Being able to meet diverse market demands enhances the competitiveness of manufacturers.

5. High Production Speed

Description

Production speed is a critical factor in the efficiency of a floor deck machine. High-speed machines can produce more deck panels in a shorter time, meeting large-scale production requirements.

Importance

- Productivity: Higher production speeds increase overall productivity, allowing manufacturers to meet tight deadlines.

- Cost Savings: Efficient production reduces labor and operational costs, improving profitability.

- Competitive Advantage: Faster production capabilities provide a competitive edge in the market by enabling quicker project completions.

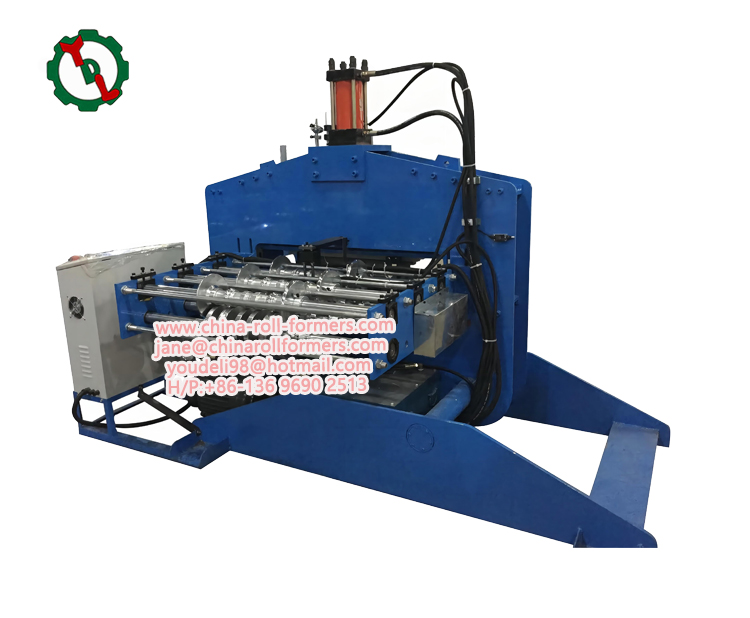

6. Precision Cutting System

Description

After the roll forming process, the deck panels need to be cut to the desired length. A precision cutting system, often featuring hydraulic or pneumatic shears, ensures clean and accurate cuts.

Importance

- Accuracy: Precise cutting minimizes material waste and ensures the deck panels fit correctly in construction applications.

- Efficiency: Automated cutting systems reduce the need for manual measurement and cutting, speeding up the production process.

- Quality: Clean cuts enhance the overall quality and appearance of the finished product.

7. Safety Features

Description

Safety features are essential to protect operators and ensure the safe operation of the floor deck machine. These may include emergency stop buttons, safety guards, and sensors.

Importance

- Operator Safety: Proper safety features reduce the risk of accidents and injuries during operation.

- Compliance: Adhering to safety standards and regulations is crucial for legal compliance and avoiding penalties.

- Machine Protection: Safety features also protect the machine from damage due to operational errors or malfunctions.

8. Energy Efficiency

Description

Energy efficiency is an important consideration in the design and operation of it. Energy-efficient machines consume less power, reducing operational costs and environmental impact.

Importance

- Cost Savings: Lower energy consumption reduces electricity bills, contributing to overall cost savings.

- Environmental Impact: Energy-efficient machines help reduce the carbon footprint of manufacturing operations, supporting sustainability goals.

- Long-Term Benefits: Investing in energy-efficient equipment provides long-term financial and environmental benefits.

9. Ease of Maintenance

Description

Regular maintenance is essential for the optimal performance and longevity of a floor deck machine. Features that facilitate easy maintenance include accessible components, modular design, and clear maintenance guidelines.

Importance

- Uptime: Easy maintenance reduces downtime, ensuring the machine remains productive for longer periods.

- Longevity: Proper maintenance extends the lifespan of the machine, providing a better return on investment.

- Cost-Effectiveness: Reducing the complexity and frequency of maintenance lowers maintenance costs and operational disruptions.

10. Customization Options

Description

Customization options allow manufacturers to tailor the floor deck machine to specific production requirements. This may include custom roller designs, specialized cutting systems, or additional automation features.

Importance

- Specific Needs: Customization ensures the machine meets the unique needs of different projects and clients.

- Flexibility: The ability to customize enhances the machine’s versatility and adaptability to changing market demands.

- Competitive Edge: Offering customized solutions provides a competitive advantage in the market, attracting more customers.

Conclusion

A floor deck machine is a vital tool in the construction industry, enabling the efficient production of high-quality floor deck panels. The key features of a floor deck machine include a robust frame structure, high-quality rollers, advanced control systems, versatility in profile sizes, high production speed, precision cutting systems, safety features, energy efficiency, ease of maintenance, and customization options. Understanding these features helps manufacturers and construction professionals choose the right machine to meet their specific needs, ensuring efficient and cost-effective production of floor deck panels.

By investing in a floor deck machine with these essential features, businesses can enhance their production capabilities, improve product quality, and achieve a competitive edge in the market.