Shutter doors are an essential component of many modern buildings, offering both security and convenience. These doors are commonly used in commercial establishments, warehouses, garages, shopping malls, and even homes, due to their ability to provide enhanced protection and efficient access. The machine used to manufacture these shutter doors is called a shutter door machine, which automates the production of these versatile and durable doors. This article will explore what this machine is, how it works, its different types, the materials used in shutter door production, and its key advantages.

What is a Shutter Door Machine?

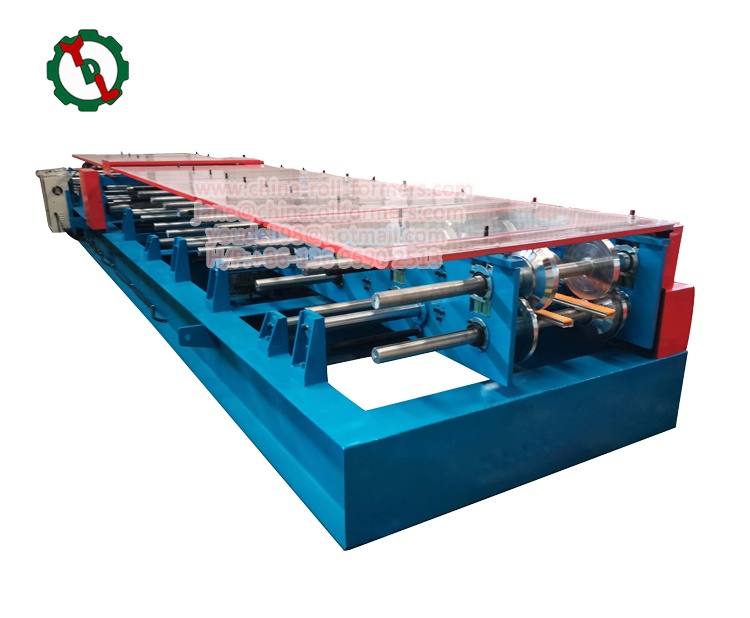

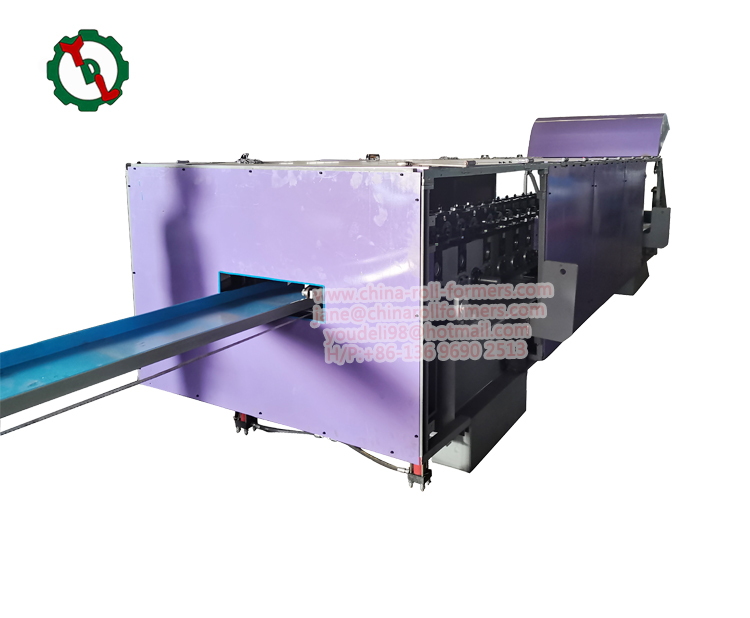

A shutter door machine is an automated system used to manufacture rolling shutter doors, which consist of interlocking slats made from materials like steel, aluminum, or PVC. It forms, cuts, punches, and rolls the slats to create the final door system. These machines can be customized for specific designs or produce standard models for bulk production. The main advantage is the automation of the process, improving speed, accuracy, and cost-effectiveness compared to manual methods.

Key Components of a Shutter Door Machine

A shutter door machine is made up of several components that work in tandem to manufacture rolling shutters. These components include:

- Uncoiler: The uncoiler unwinds the metal coils that are fed into the machine. The coil is the raw material used for the slats of the shutter door. The uncoiler helps to feed the coil through the machine smoothly, ensuring an uninterrupted production process.

- Roll Forming Machine: The roll forming machine is the heart of the shutter door machine. It is responsible for shaping the metal strip into the interlocking slats that make up the shutter door. The metal strip is fed into the machine and passes through a series of rollers, each designed to progressively bend the material into the desired shape. This process ensures uniformity and precision in the manufacturing of each slat.

- Cutting Mechanism: After the slats have been shaped, the cutting mechanism ensures that the slats are the correct length. This part of the machine uses high-speed blades or shear cutters to precisely cut the slats to the desired size, reducing waste and ensuring accuracy in the final product.

- Punching and Embossing Station: Some machines include stations for punching holes or embossing patterns onto the slats, enhancing the aesthetic appeal or adding functional openings for locks and other components.

- Assembly Station: After the slats are cut and shaped, they are moved to the assembly station, where they are connected to each other to form the complete door. The assembly process involves aligning and interlocking the slats, which are then attached to the rolling system that will allow the door to open and close smoothly.

- Rolling System: The rolling system is a crucial part of the shutter door machine. It allows the door to be rolled up into a compact coil when it is not in use. The system includes a motorized drum and side rails that guide the slats into the coiled configuration. This feature is especially important for applications like garages or warehouses, where space-saving is a priority.

- Control Panel: The operator uses this panel to adjust settings like speed, cut length, and shaping parameters, with some models offering automated controls for increased efficiency.

- Output Conveyor: After the shutter door is formed and assembled, the output conveyor moves the finished product for packaging, inspection, or delivery. This helps in managing the flow of production and ensures that the final products are efficiently processed for shipment.

Types of Shutter Door Machines

There are various machines designed for manufacturing shutter doors, each catering to specific needs. The choice depends on factors such as material, design, and automation level. Below are the main types:

1. Manual Shutter Door Machines

Manual machines are basic and often smaller machines designed for low-volume production. They are operated by hand, with the operator manually adjusting settings and guiding the material through the production process. While they are less efficient than automatic machines, manual machines are cost-effective and suitable for small businesses or workshops that do not require large-scale production.

2. Semi-Automatic Shutter Door Machines

Semi-automatic machines combine manual and automated processes. The machine may automatically form and cut the slats, but the operator is still required to handle certain tasks, such as loading material and making adjustments. These machines are typically faster than manual machines and are suitable for businesses that need medium-level production volumes.

3. Fully Automatic Shutter Door Machines

Fully automatic machines are the most advanced and efficient option. These machines require minimal human intervention and are capable of high-volume production with precision and consistency. They are designed to automatically handle all steps of the manufacturing process, including uncoiling, forming, cutting, punching, and assembling the shutter door. Fully automatic machines are ideal for large-scale manufacturers or businesses looking to maximize productivity and reduce labor costs.

4. Custom Shutter Door Machines

In some cases, businesses require customized doors to meet specific needs, such as unique sizes, designs, or materials. These machines are equipped with specialized features that allow for the production of tailored doors. They can be designed with additional options for embossing, branding, or cutting specific patterns or holes in the slats, ensuring the final product meets customer specifications.

Materials Used in Shutter Door Manufacturing

A shutter door machine can work with various materials depending on the application and customer preferences. Some of the most commonly used materials for shutter doors include:

1. Steel

Steel is one of the most popular materials for manufacturing shutter doors because of its strength, durability, and resistance to external elements. Steel shutter doors are often used in commercial and industrial settings where high security is essential.

2. Aluminum

Aluminum is a lightweight, rust-resistant material that is often used for shutter doors in areas exposed to harsh weather conditions. Aluminum doors are suitable for both residential and commercial properties, providing a good balance between strength and weight.

3. PVC

PVC (polyvinyl chloride) is another material used in the production of shutter doors. PVC is lightweight, resistant to corrosion, and offers excellent insulation properties. PVC shutters are typically used for residential applications, especially in areas requiring insulation from heat or noise.

4. Stainless Steel

Stainless steel is another strong and corrosion-resistant material that is used for high-end shutter doors. It is typically used in environments where both aesthetics and durability are critical, such as in high-end retail stores or secure facilities.

5. Galvanized Steel

Galvanized steel, coated with a layer of zinc to prevent rust, is also commonly used for shutter door manufacturing. Galvanized steel is highly resistant to corrosion and offers long-lasting durability, making it ideal for outdoor or industrial applications.

How Does a Shutter Door Machine Work?

The shutter door machine works by following a series of steps to convert raw metal coils into fully functional shutter doors. Here is an overview of the process:

- Coil Feeding: The raw material, typically a metal coil, is fed into the machine using the uncoiler.

- Roll Forming: The metal strip passes through a series of rollers that gradually shape it into the interlocking slats that form the shutter door.

- Cutting: After the slats are formed, they are cut to the required length by the machine’s cutting mechanism.

- Punching and Embossing: If needed, punching or embossing is done to add holes or patterns on the slats.

- Assembly: The cut and shaped slats are assembled together, interlocked, and connected with the necessary hardware.

- Rolling: The completed slats are then moved into the rolling system, where they are rolled up to form the compact shutter door.

- Packaging: The finished shutter door is transported to the output conveyor and packaged for shipping.

Conclusion

The shutter door machine plays a crucial role in the modern manufacturing of rolling shutter doors, automating and streamlining the production process to achieve high-quality, durable, and customized products. With various types of machines available, ranging from manual to fully automated systems, manufacturers can choose the right machine to meet their production needs. By offering a range of materials such as steel, aluminum, PVC, and stainless steel, allowing for a variety of applications in residential, commercial, and industrial sectors. Ultimately, these machines are essential for providing secure and reliable door solutions across multiple industries globally.