In the world of modern manufacturing and construction, precision and efficiency are paramount. One of the critical tools that contribute to these objectives is the step tile roll forming machine. This specialized equipment plays a significant role in producing step tiles used in various architectural and structural applications. This article delves deeply into the step tile roll forming machine, exploring its functions, benefits, components, and applications to provide a comprehensive understanding of this essential manufacturing tool.

Understanding Step Tile Roll Forming Machines

A step tile roll forming machine is a sophisticated piece of equipment designed to create step tiles through a continuous and automated process. These machines utilize roll forming technology, which involves feeding metal strips through a series of rollers to achieve the desired shape and profile. The term “step tile” refers to tiles with a stepped or layered design, often used for roofing, flooring, and decorative purposes.

How Step Tile Roll Forming Machines Work

The operation of a step tile roll forming machine involves several key stages:

- Material Feeding: The process begins with the feeding of metal strips, typically made from steel or aluminum, into the machine. These strips are usually pre-coated to enhance durability and appearance.

- Roll Forming Process: The metal strips pass through a series of rollers, each designed to progressively shape the material. The rollers are arranged in a specific sequence to ensure the precise formation of the step tile profile. As the metal moves through the rollers, it is gradually shaped into the final form.

- Cutting and Forming: Once the metal strip reaches the desired length and shape, it is cut to size. Some machines may also include additional forming processes to add specific details or features to the tiles.

- Quality Control: The finished tiles undergo quality control checks to ensure they meet the required specifications and standards. This may involve measuring dimensions, checking for defects, and verifying the overall quality of the tiles.

- Packaging: After quality control, the tiles are packaged for distribution and installation. Packaging is crucial to protect the tiles during transportation and handling.

Key Components of a Step Tile Roll Forming Machine

A step tile roll forming machine comprises several essential components, each playing a crucial role in the manufacturing process:

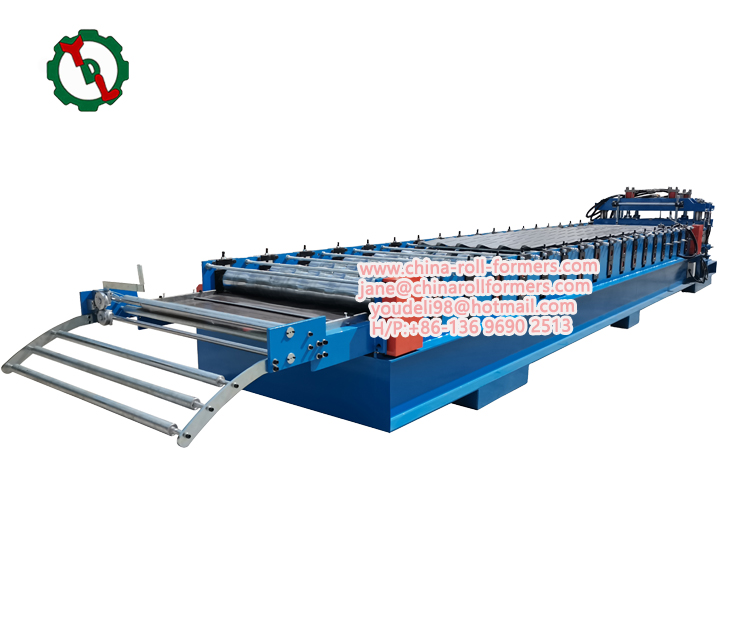

- Uncoiler: This component is responsible for feeding the metal strips into the machine. It unwinds the coils of metal and ensures a steady and consistent feed rate.

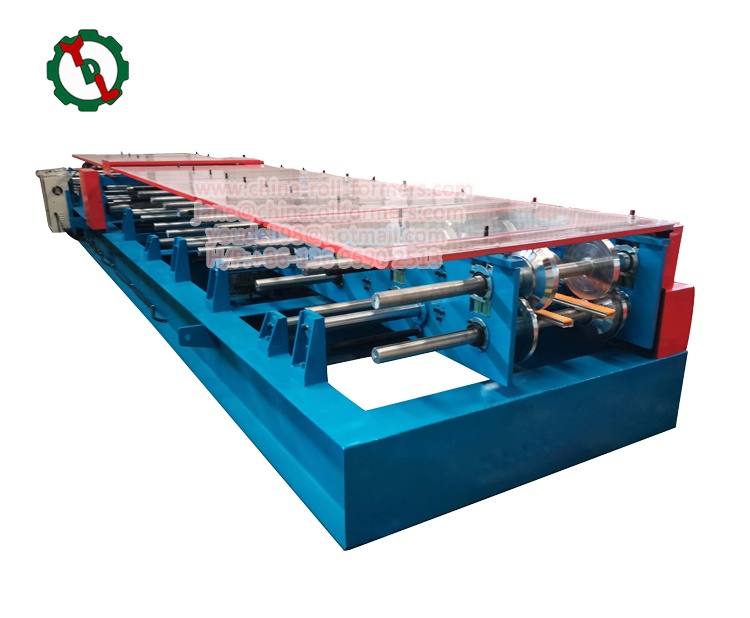

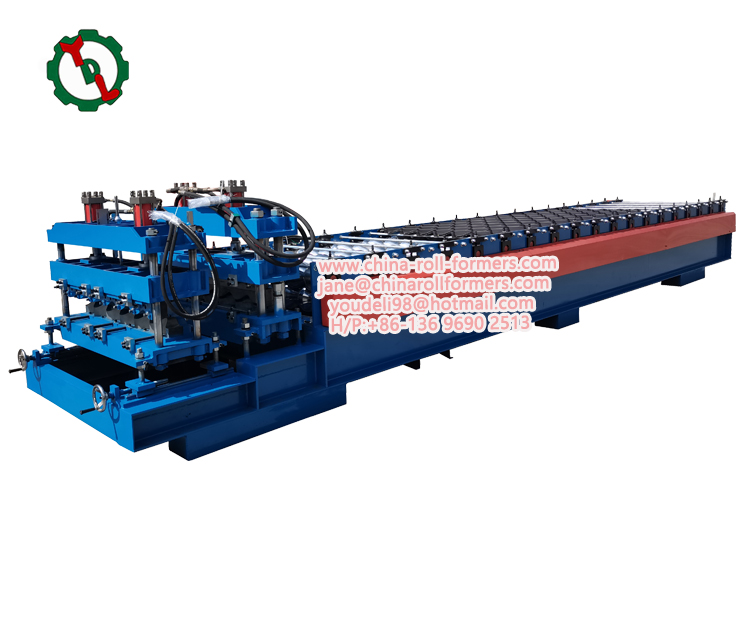

- Roll Forming Stations: The heart of the machine, these stations consist of multiple rollers arranged in a specific sequence. Each roller performs a particular shaping task, gradually transforming the metal strip into the step tile profile.

- Cutting Device: After forming, the metal strip is cut to the required length. The cutting device ensures accurate and clean cuts to achieve the desired tile dimensions.

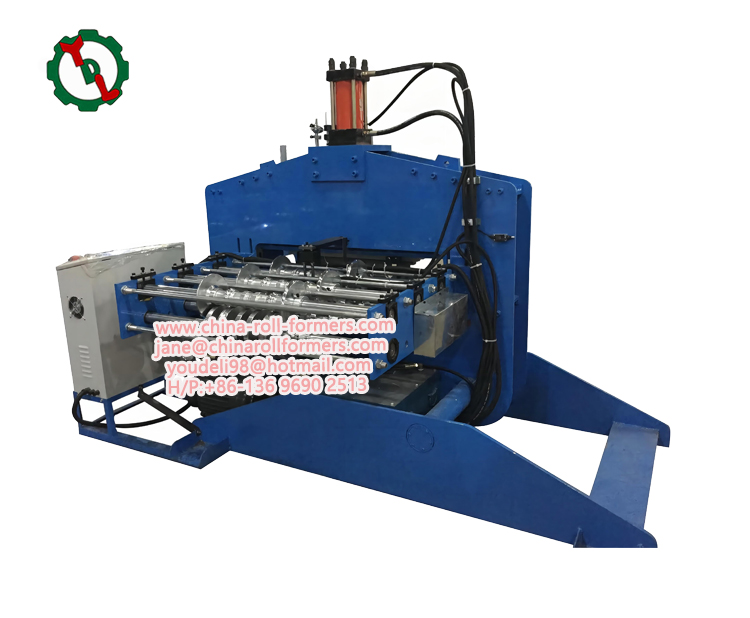

- Hydraulic System: Many roll forming machines use a hydraulic system to operate various components, including the cutting device and forming rollers. This system provides the necessary force and control for precise operations.

- Control Panel: The control panel allows operators to adjust settings, monitor the machine’s performance, and troubleshoot any issues. Modern machines often feature computerized controls for enhanced precision and ease of use.

- Conveyor System: This system transports the finished tiles from the forming area to the packaging station. It ensures a smooth and efficient workflow, minimizing manual handling.

Benefits of Using a Step Tile Roll Forming Machine

They offers several advantages that make it a valuable tool in manufacturing and construction:

- High Precision: Roll forming technology ensures high precision in producing step tiles, with consistent dimensions and shapes. This precision is crucial for applications where uniformity and accuracy are essential.

- Efficiency: The automated nature of roll forming machines allows for high production rates with minimal manual intervention. This efficiency translates to reduced labor costs and faster manufacturing times.

- Versatility: They can produce a wide range of step tile profiles and sizes. This versatility makes them suitable for various applications, from residential roofing to commercial flooring.

- Cost-Effective: The use of roll forming technology reduces material waste and minimizes production costs. The continuous process also allows for long runs of tiles, further reducing costs per unit.

- Durability: The metal tiles produced by roll forming machines are often more durable and resilient than those made through other methods. This durability contributes to the longevity of the finished product.

Applications of Step Tile Roll Forming Machines

Step tiles produced by roll forming machines find applications in various industries and settings:

- Roofing: Step tiles are commonly used in roofing systems, providing both functional and aesthetic benefits. Their stepped design enhances water drainage and adds a distinctive appearance to buildings.

- Flooring: In flooring applications, step tiles offer a durable and visually appealing surface. They are often used in commercial and residential settings to create attractive and functional flooring solutions.

- Facade Cladding: Step tiles can be used as part of facade cladding systems, adding texture and visual interest to building exteriors. They contribute to both the aesthetics and protection of the building’s facade.

- Decorative Features: Beyond functional applications, step tiles are also used for decorative purposes. Their unique design can enhance the visual appeal of various architectural elements.

Factors to Consider When Choosing a Step Tile Roll Forming Machine

Selecting the right step tile roll forming machine involves considering several factors to ensure it meets your production needs:

- Production Capacity: Assess the machine’s production capacity to ensure it aligns with your manufacturing requirements. Consider factors such as production speed, tile dimensions, and material types.

- Customization Options: Determine whether the machine offers customization options for producing different tile profiles and sizes. This flexibility can be valuable for meeting diverse project requirements.

- Quality and Reliability: Choose a machine from a reputable manufacturer known for producing high-quality and reliable equipment. Quality and reliability are crucial for minimizing downtime and ensuring consistent performance.

- Ease of Operation: Consider the ease of operation and maintenance when selecting a machine. Look for user-friendly controls, clear instructions, and support from the manufacturer.

- Cost: Evaluate the cost of the machine in relation to its features and capabilities. Consider the long-term benefits and potential cost savings associated with using the machine.

Maintenance and Care for Step Tile Roll Forming Machines

Proper maintenance is essential for ensuring the longevity and optimal performance of a step tile roll forming machine. Key maintenance practices include:

- Regular Cleaning: Keep the machine clean by removing dust, debris, and metal shavings. Regular cleaning prevents buildup that can affect performance and accuracy.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations. Proper lubrication reduces friction and wear, extending the machine’s lifespan.

- Inspection: Conduct regular inspections to identify any signs of wear, damage, or misalignment. Addressing issues promptly can prevent more significant problems and minimize downtime.

- Calibration: Periodically check and calibrate the machine to ensure accurate forming and cutting. Proper calibration is crucial for maintaining the quality and consistency of the finished tiles.

- Operator Training: Ensure that operators are trained in the proper use and maintenance of the machine. Well-trained operators are better equipped to handle the machine effectively and address any issues that may arise.

Conclusion

The step tile roll forming machine is a vital tool in modern manufacturing and construction, offering precision, efficiency, and versatility in producing step tiles. Its advanced technology and automated processes make it an invaluable asset for various applications, from roofing and flooring to decorative features and facade cladding. By understanding its operation, benefits, and maintenance requirements, manufacturers and construction professionals can leverage the capabilities of step tile roll forming machines to achieve high-quality results and meet their project needs.