What is a Step Tile Roll Forming Machine?

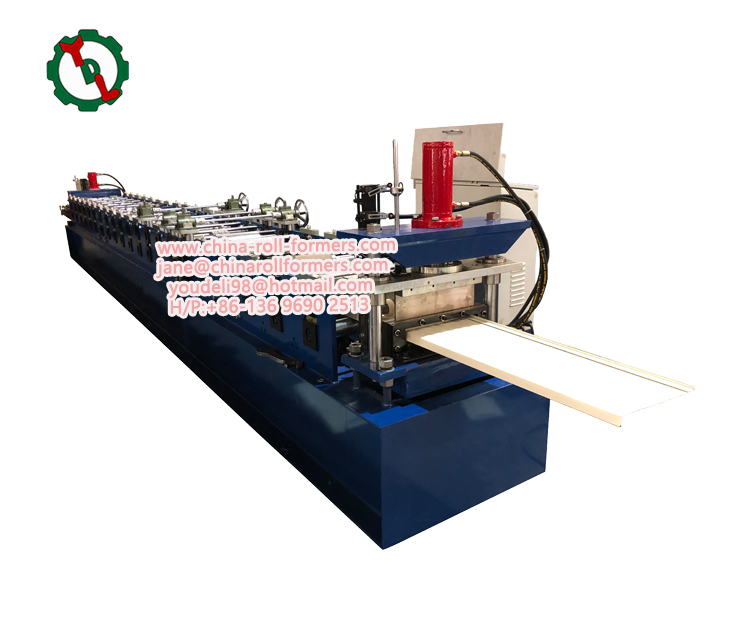

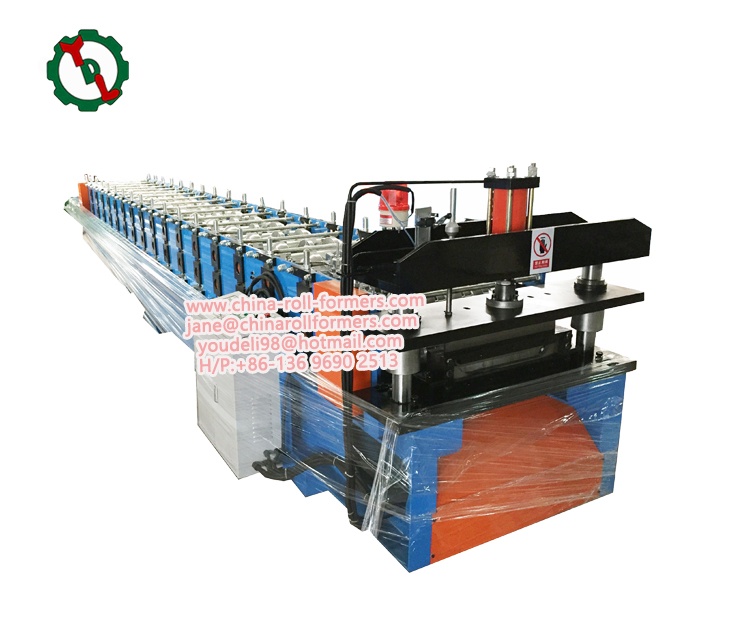

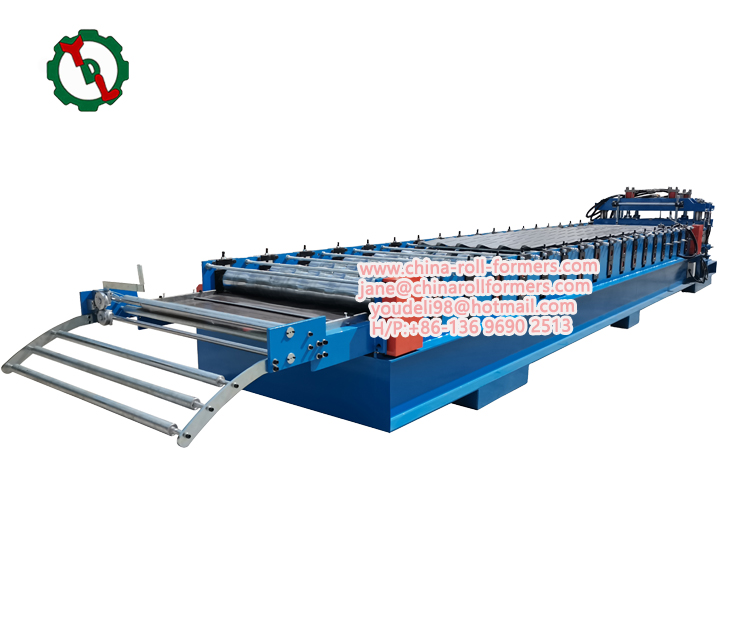

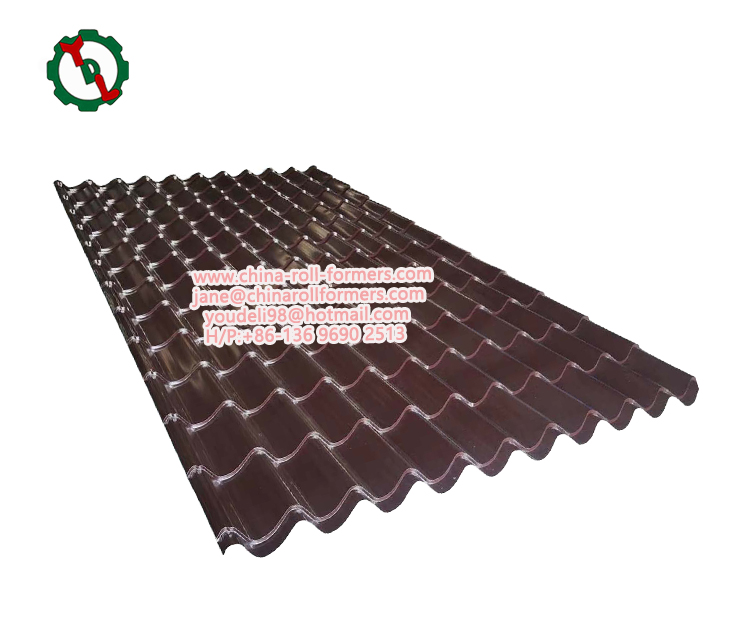

A step tile roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce step tiles, also known as Spanish tiles or profiled tiles. It is a type of roll forming equipment that is designed to produce step tiles from metal coils. The machine operates by passing a continuous strip of metal through a series of rollers, which gradually shape the metal into the desired profile. The process is continuous, allowing for the efficient production of large quantities of step tiles with consistent quality.

Advancements in technology have revolutionized the manufacturing industry, and the roll forming process is no exception. These tiles are commonly used for roofing purposes due to their distinctive shape and aesthetic appeal. In this article, we will explore what it is, how it works, and its key components.

Working Principles of a Step Tile Roll Forming Machine

The operation of a step tile roll forming machine can be divided into several key steps:

- Material Loading: The process begins with loading a coil of metal material, such as steel or aluminum, onto the machine. The coil is mounted on a decoiler, which feeds the material into the machine at a controlled rate.

- Material Feeding: The metal strip is fed into the roll forming machine, where it passes through a series of rollers. Each set of rollers is designed to gradually bend the metal strip into the desired shape, forming the profile of the step tile.

- Profile Shaping: As the metal strip passes through the rollers, it undergoes a series of bending and shaping operations. The rollers are configured in such a way that they progressively shape the metal into the final step tile profile.

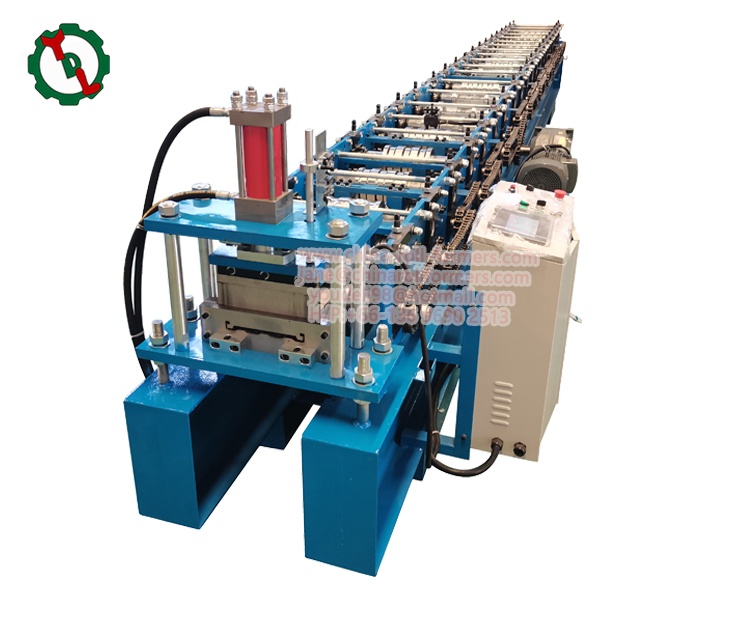

- Cutting: Once the metal strip has been formed into the desired profile, it is cut to the appropriate length. The cutting operation is typically performed using a flying cutoff die, which cuts the metal strip as it moves through the machine.

- Stacking: Finally, the finished step tiles are stacked and ready for further processing or shipment. Some machines may include an automatic stacking system, which can stack the tiles in a neat and organized manner for easy handling.

Key Components of a Step Tile Roll Forming Machine

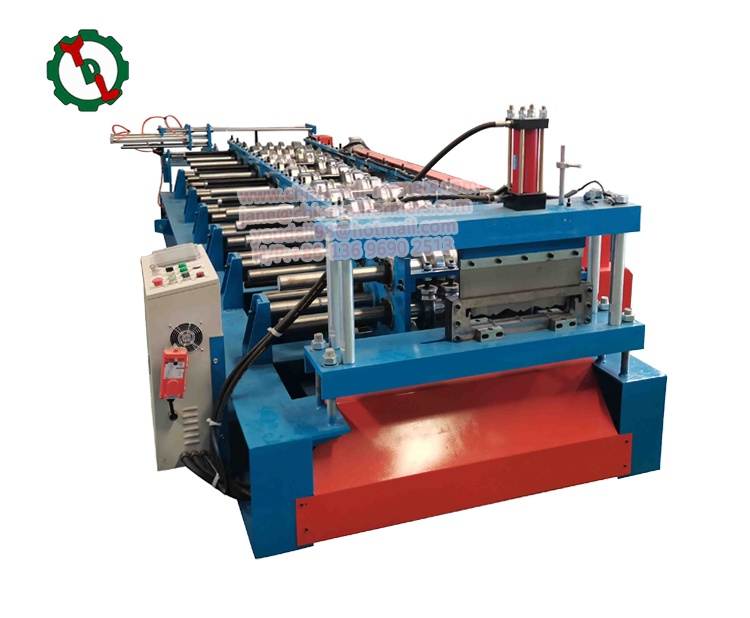

A step ladder brick forming machine typically consists of the following key components:

- Decoiler: The decoiler is used to hold and feed the coil of metal material into the machine. It ensures a continuous supply of material during the roll forming process.

- Roll Forming Mill: The roll forming mill is the heart of the machine, where the metal strip is shaped into the final step tile profile. It consists of a series of rollers that are arranged in a sequence to gradually bend the metal strip into shape.

- Cutting System: The cutting system is used to cut the metal strip into individual step tiles. It typically consists of a flying cutoff die, which can cut the metal strip with high precision and speed.

- Control System: The control system is used to operate and monitor the machine. It allows the operator to set parameters such as speed, length, and cutting dimensions, ensuring consistent quality and performance.

Benefits of Using a Step Tile Roll Forming Machine

There are several benefits to using a step tile roll forming machine for the production of step tiles:

- High Efficiency: Roll forming machines are capable of producing large quantities of step tiles in a relatively short period. This high level of efficiency can result in cost savings and increased productivity for manufacturers.

- Consistent Quality: Roll forming machines are designed to produce step tiles with consistent quality and dimensions. This ensures that each tile meets the required specifications, leading to fewer defects and rejections.

- Versatility: Roll forming machines can be easily adjusted to produce different profiles and sizes of step tiles. This versatility allows manufacturers to quickly switch between different products, making the machine suitable for a wide range of applications.

- Cost-Effectiveness: Roll forming machines are a cost-effective solution for producing step tiles. The automated nature of the machine reduces the need for manual labor, resulting in lower production costs.

The Role of Step Tile Roll Forming Machines in the Roofing Industry

Step ladder brick forming machines play a crucial role in the roofing industry by providing a streamlined and efficient method for producing step tiles. Their versatility allows for the production of a wide range of step tile profiles to meet diverse customer needs. These machines ensure consistent quality and dimensions, reducing the risk of defects and rejections.

Moreover, step tile roll forming machines offer significant cost savings for manufacturers. Their automated nature reduces the need for manual labor, leading to lower production costs and increased profitability. The high efficiency of these machines also results in shorter production times, allowing manufacturers to meet tight deadlines and fulfill customer orders promptly.

Additionally, these machines contribute to the sustainability of the roofing industry by producing step tiles efficiently and with minimal waste. This helps reduce the environmental impact of roofing manufacturing processes. Furthermore, the consistent quality and precision of step tiles produced using these machines contribute to the overall durability and longevity of roofing systems, ensuring that roofs remain intact and functional for years to come.

Conclusion

In conclusion, a step tile roll forming machine is a valuable piece of equipment for the manufacturing of step tiles. Its ability to produce high-quality tiles efficiently and cost-effectively makes it an essential tool for manufacturers in the roofing industry. By understanding how these machines work and their key components, manufacturers can make informed decisions about their use in their operations.