Introduction

Roll forming machines are essential tools in the manufacturing industry, used to create a variety of metal profiles and panels with consistent shapes and dimensions. One specialized type of roll forming machine is the wall panel roll forming machine, which is specifically designed to produce metal wall panels used in construction and other applications. In this article, we will provide an overview of roll forming machines in general and then focus on the specifics of it.

Overview of Roll Forming Machines

Roll forming machines are machines that shape metal coils or sheets into continuous profiles by passing them through a series of rollers. These rollers gradually bend the metal into the desired shape, forming a uniform and precise profile. Roll forming machines can produce a wide range of profiles, including panels, channels, and tubes, with consistent dimensions and high precision.

Introduction to Wall Panel Roll Forming Machines

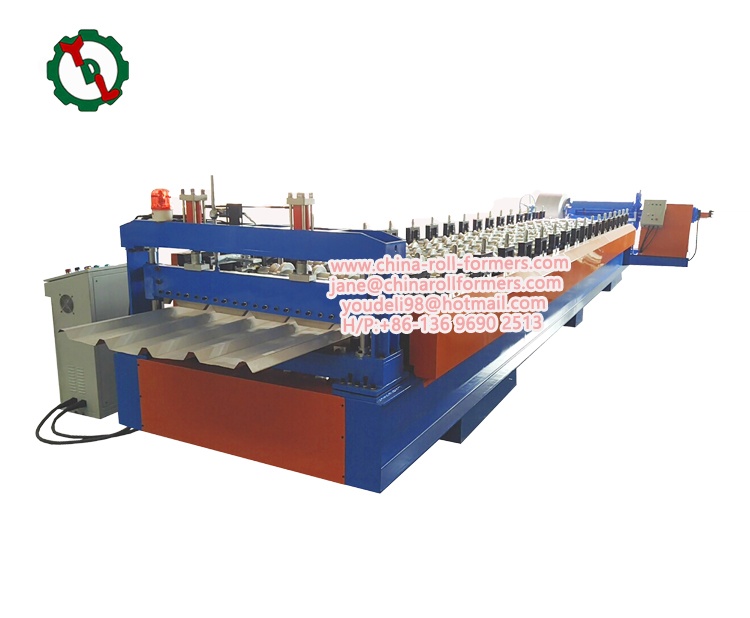

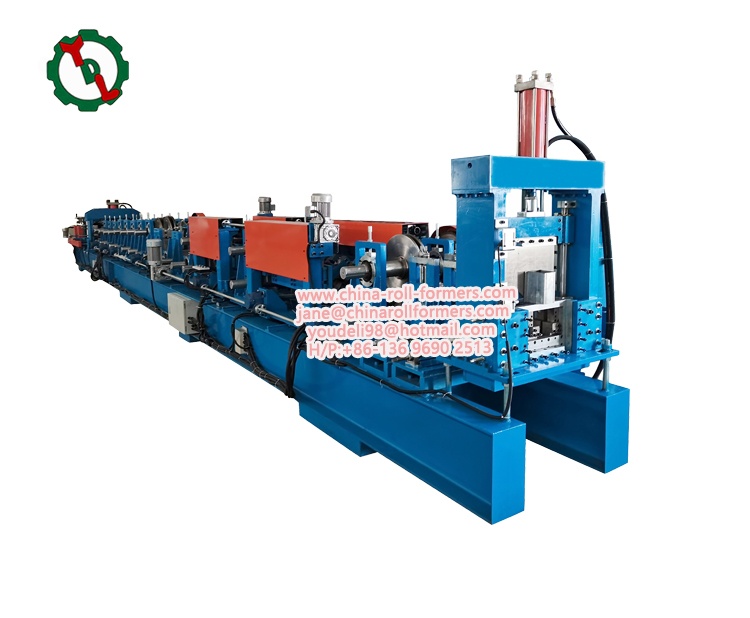

are a type of roll forming machine specifically designed to produce metal wall panels. These machines consist of several main components, including a decoiler, guiding equipment, roll forming stations, cutting equipment, and a control system.

The process begins with a coil of metal being loaded onto the decoiler. The metal strip is then fed into the machine, where it passes through a series of roll forming stations. Each station is equipped with rollers that gradually shape the metal into the desired profile of the wall panel.

Once the metal has been formed, it passes through a cutting station where it is cut to the required length. Finally, the finished panels are stacked or packaged for shipping.

Wall panel roll forming machines can produce a variety of wall panels, including corrugated panels, insulated panels, and standing seam panels. These panels are used in a wide range of applications, including commercial buildings, residential homes, and agricultural structures.

They are a specialized type of roll forming machine used to produce metal wall panels. These machines are an essential tool in the construction industry, providing a cost-effective and efficient way to manufacture high-quality wall panels for various applications.

Understanding Wall Panel Roll Forming Machines

A wall panel roll forming machine is a specialized type of equipment used in manufacturing to create metal wall panels. These machines consist of several key components, each playing a crucial role in the production process.

- Decoiler: The decoiler is responsible for holding and feeding the coil of metal into the machine. It ensures a continuous supply of material for the roll forming process.

- Guiding Equipment: Guiding equipment helps to ensure that the metal strip is properly aligned as it moves through the machine. This helps to prevent misalignment and ensures that the panels are produced accurately.

- Roll Forming Stations: The roll forming stations are the heart of the machine. These stations consist of a series of rollers that gradually shape the metal strip into the desired profile of the wall panel. Each station is responsible for a specific part of the panel’s shape, and multiple stations are used to achieve the final profile.

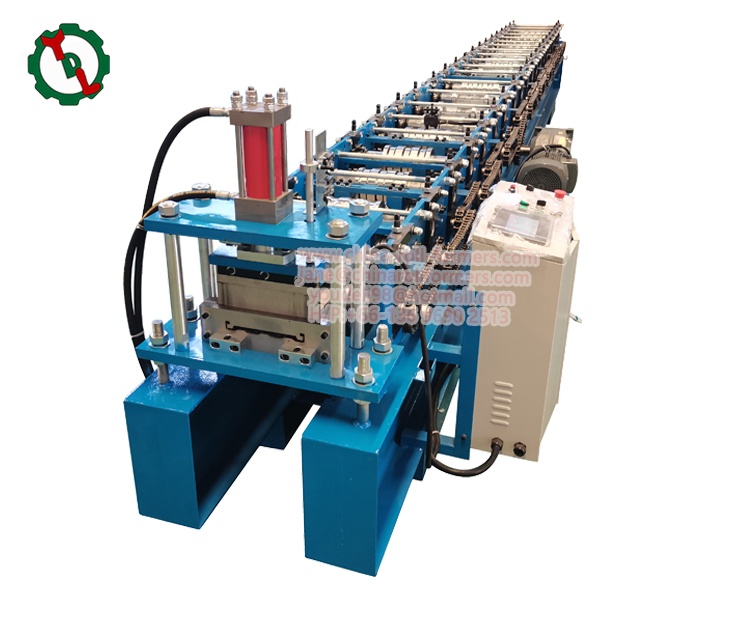

- Cutting Equipment: Once the metal strip has been formed into the desired shape, it passes through a cutting station where it is cut to the required length. This ensures that each panel is the correct size for its intended application.

- Control System: The control system is responsible for overseeing the entire operation of the machine. It controls the speed of the machine, the alignment of the metal strip, and the cutting process to ensure that each panel is produced accurately and efficiently.

How the Machine Works to Produce Wall Panels

The operation of a wall panel roll forming machine begins with the loading of a coil of metal onto the decoiler. The metal strip is then fed into the machine and passed through the guiding equipment to ensure proper alignment.

As the metal strip moves through the machine, it passes through a series of roll forming stations. Each station gradually shapes the metal strip into the desired profile of the wall panel. The metal strip is then cut to the required length before being stacked or packaged for shipping.

Different Types of Wall Panels That Can Be Produced

They can produce a wide variety of wall panels, including:

- Corrugated Panels: These panels have a wavy or corrugated profile and are commonly used for roofing and siding applications.

- Insulated Panels: These panels are constructed with an insulating material sandwiched between two layers of metal, providing both structural support and thermal insulation.

- Standing Seam Panels: These panels feature vertical ribs or seams that stand up from the surface of the panel, creating a distinctive look and providing additional strength.

Benefits of Using a Wall Panel Roll Forming Machine

There are several benefits to using a wall panel roll forming machine, including:

Efficiency and Speed of Production: These machines can produce wall panels quickly and efficiently, making them ideal for high-volume production.

Precision and Consistency in Panel Dimensions: They can produce panels with tight tolerances, ensuring that each panel is exactly the same size and shape.

Cost-Effectiveness Compared to Other Methods: The automated nature of these machines reduces labor costs and increases productivity, resulting in lower overall production costs.

Applications of Wall Panel Roll Forming Machines

They are used in a variety of industries for their versatility and efficiency. Some of the industries where these machines are commonly used include:

- Construction: They are extensively used in the construction industry to produce panels for building exteriors, interior walls, roofing, and cladding. These panels are durable, weather-resistant, and can be customized to suit different architectural styles.

- Manufacturing: In the manufacturing sector, they are used to produce panels for various applications, such as enclosures, partitions, and equipment housing. These panels are used in factories, warehouses, and other industrial settings to create functional and efficient spaces.

Examples of wall panel applications in construction and manufacturing include:

- Siding: Wall panels are commonly used as siding for residential and commercial buildings. They provide insulation, weather protection, and aesthetic appeal.

- Roofing: Wall panels are also used as roofing material, providing a durable and weather-resistant covering for buildings.

- Interior Wall Cladding: Wall panels can be used to clad interior walls, providing a decorative and easy-to-maintain surface.

Choosing the Right Wall Panel Roll Forming Machine

When selecting a wall panel roll forming machine, several factors should be considered to ensure that it meets your production needs and requirements:

- Panel Size and Thickness: The machine should be capable of producing panels of the desired size and thickness for your application.

- Production Speed: Consider the production speed of the machine and whether it meets your production volume requirements.

- Material Compatibility: Ensure that the machine is compatible with the materials you plan to use for your wall panels, such as steel, aluminum, or other metals.

- Customization Options: Look for machines that offer customization options, such as the ability to change panel profiles or add features like embossing or perforation.

Maintenance and Care of Wall Panel Roll Forming Machines

Regular maintenance is essential to ensure the optimal performance and longevity of a Wall panel forming machine. Some key maintenance procedures include:

- Cleaning and Lubrication: Regularly clean and lubricate the machine to prevent rust and ensure smooth operation.

- Inspection and Repair: Periodically inspect the machine for worn or damaged parts and replace them as needed.

- Safety Precautions: Follow all safety precautions when operating the machine, including wearing appropriate protective gear and ensuring that the machine is properly grounded.

By considering these factors and following proper maintenance procedures, you can ensure that your wall panel roll forming machine operates efficiently and produces high-quality panels for your applications.

Conclusion

In summary, wall panel roll forming machines play a crucial role in modern manufacturing and construction industries. These machines offer numerous benefits, including efficiency and speed of production, precision and consistency in panel dimensions, and cost-effectiveness compared to other methods. They are used in various industries for applications such as siding, roofing, and interior wall cladding. The importance of these machines cannot be overstated, as they enable the efficient and cost-effective production of high-quality wall panels that are essential for modern buildings and structures.